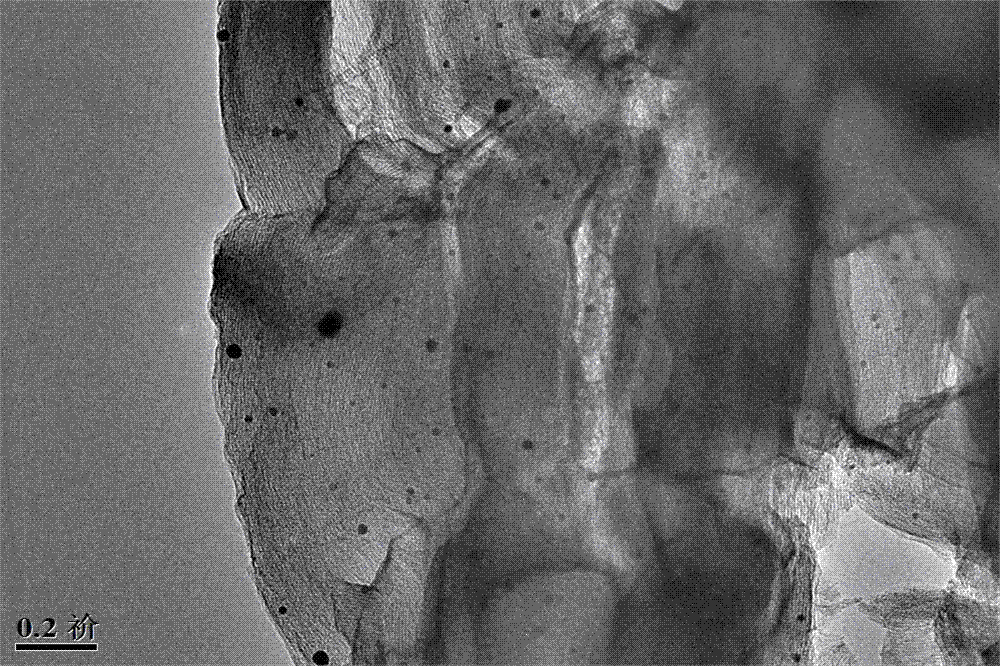

Controllable preparation method of an ordered mesoporous carbon electrocatalyst with metal nanoparticles uniformly embedded in the pore wall structure

A metal nanoparticle, electrocatalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem that the specific surface area is not large enough and the active components are easy to agglomerate and other problems, to achieve the effect of high selectivity, good electrocatalytic effect and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) First, prepare a mixed aqueous solution of palladium chloride and copper nitrate containing 0.5g / LPd element and 0.25g / LCu element for use;

[0031] (2) Next, add 1 g of SBA-15 to 20 mL of the aqueous solution (50 g / L) obtained in step (1) and stir for 3 h, then filter, wash, and dry at 60 °C;

[0032] (3) Next, the sample obtained in step (2) was placed in a tube furnace, calcined at 400 °C for 1 h under a nitrogen atmosphere, and then reduced for 3 h at 400 °C under a hydrogen atmosphere, and then uniformly dispersed Pd- Cu / SBA-15 material;

[0033] (4) Then, configure a mixed solution of sucrose and sulfuric acid, wherein the volume of sucrose is the pore volume of the Pd-Cu / SBA-15 material obtained in step (3);

[0034] (5) Immerse the material obtained in step (3) in the solution obtained in step (4), stir evenly and place in an oven to dry at 100°C and 160°C for 6 hours respectively. Under the dehydration of sulfuric acid, the sucrose Dehydration into carbon...

Embodiment 2

[0040] (1) First, prepare a mixed aqueous solution of palladium chloride and copper nitrate containing 0.5g / LPd element and 0.25g / LCu element for use;

[0041] (2) Next, add 1 g of SBA-15 to 20 mL of the aqueous solution (50 g / L) obtained in step (1) and stir for 3 h, then filter, wash, and dry at 60 °C;

[0042] (3) Next, the sample obtained in step (2) was placed in a tube furnace, calcined at 400 °C for 1 h under a nitrogen atmosphere, and then reduced for 3 h at 400 °C under a hydrogen atmosphere, and then uniformly dispersed Pd- Cu / SBA-15 material;

[0043] (4) Then, configure a mixed solution of sucrose and sulfuric acid, wherein the volume of sucrose is the pore volume of the Pd-Cu / SBA-15 material obtained in step (3);

[0044] (5) Immerse the material obtained in step (3) in the solution obtained in step (4), stir evenly and place in an oven to dry at 100°C and 160°C for 6 hours respectively. Under the dehydration of sulfuric acid, the sucrose Dehydration into carbon...

Embodiment 3

[0051] (1) First, prepare a mixed aqueous solution of palladium chloride and copper nitrate containing 0.5g / LPd element and 0.25g / LCu element for use;

[0052] (2) Next, add 1 g of SBA-15 to 20 mL of the aqueous solution (50 g / L) obtained in step (1) and stir for 3 h, then filter, wash, and dry at 60 °C;

[0053] (3) Next, the sample obtained in step (2) was placed in a tube furnace, calcined at 400 °C for 1 h under a nitrogen atmosphere, and then reduced for 3 h at 400 °C under a hydrogen atmosphere, and then uniformly dispersed Pd- Cu / SBA-15 material;

[0054] (4) Then, configure a mixed solution of sucrose and sulfuric acid, wherein the volume of sucrose is the pore volume of the Pd-Cu / SBA-15 material obtained in step (3);

[0055] (5) Immerse the material obtained in step (3) in the solution obtained in step (4), stir evenly and place in an oven to dry at 100°C and 160°C for 6 hours respectively. Under the dehydration of sulfuric acid, the sucrose Dehydration into carbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com