Heterogeneous Cu-Mn-Ce Fenton-like catalyst, and preparation method and use thereof

A cu-mn-ce, heterogeneous technology, applied in the field of heterogeneous Cu-Mn-Ce Fenton catalyst and its preparation, can solve the problems of uneven dispersion of active components, small contact surface, limited catalytic activity, etc. , to achieve the effect of wide application range of pH, uniform and orderly pores, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) First, configure a mixed solution of 1mol / L copper nitrate, manganese nitrate and cerium nitrate (a mixed solution with copper nitrate, manganese nitrate and cerium nitrate concentration of 1mol / L each) for use;

[0029] (2) Next, repeatedly dip 1g of SBA-15 into 50mL of the above-mentioned mixed solution of copper nitrate, manganese nitrate and cerium nitrate (20g / L) and stir for 8h, then filter and dry;

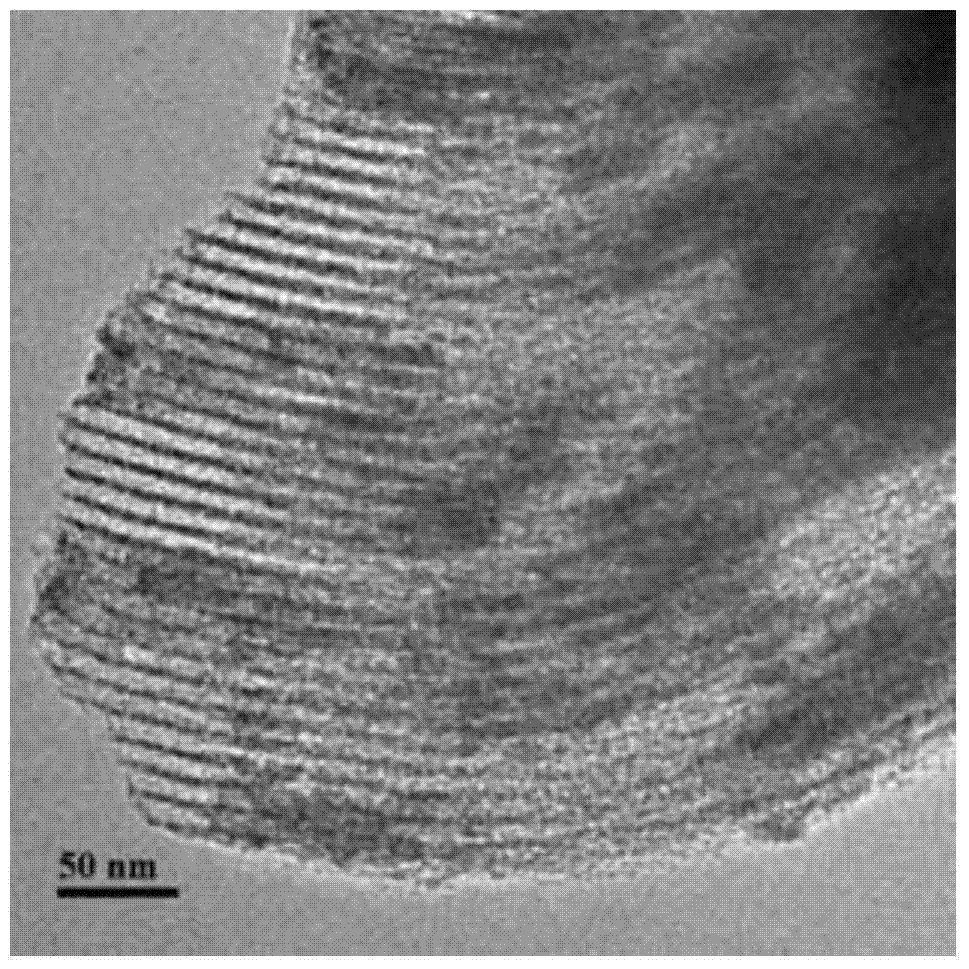

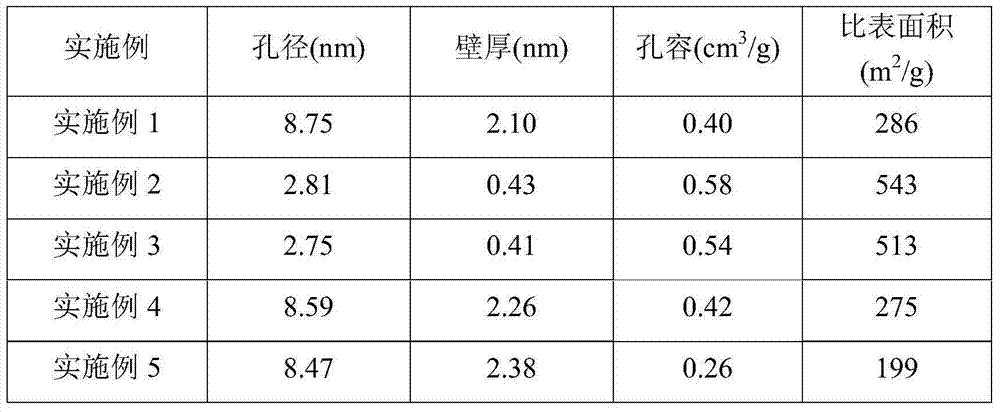

[0030] (3) Next, place the sample obtained in step (2) in a muffle furnace and calcinate at 300°C for 6 hours to obtain a heterogeneous Cu-Mn-Ce-based Fenton catalyst. The TEM picture is as follows figure 1 shown. Depend on figure 1 It can be seen that the catalyst shows a wide range of ordered strip structures along the [110] direction, and the shaded part in the figure is the active metal oxide successfully supported on the mesoporous silica. Its structural parameters are shown in Table 1;

[0031] (4) Then, add 0.2 g / L heterogeneous Cu-Mn-Ce Fenton catalyst...

Embodiment 2

[0034] (1) First, configure a mixed solution of 0.1mol / L copper nitrate, manganese nitrate and cerium nitrate for use (a mixed solution with a concentration of 0.1mol / L each of copper nitrate, manganese nitrate and cerium nitrate);

[0035] (2) Next, repeatedly dip 0.5g of MCM-41 into the above 50mL mixed solution of copper nitrate, manganese nitrate and cerium nitrate (10g / L) and stir for 4h, then filter and dry;

[0036] (3) Next, place the sample obtained in step (2) in a muffle furnace and calcinate at 500°C for 6 hours to obtain a heterogeneous Cu-Mn-Ce-based Fenton catalyst;

[0037] (4) Then, add 0.1 g / L heterogeneous Cu-Mn-Ce Fenton catalyst and 0.2 mol / L hydrogen peroxide to the 2000 mg / L high-concentration acid red 1 solution, adjust the pH to 3, and heat the solution to 70 ℃, let the system react for 210min, the results are shown in Table 2.

Embodiment 3

[0039] (1) First, configure a mixed solution of 0.5mol / L copper nitrate, manganese nitrate and cerium nitrate (a mixed solution with copper nitrate, manganese nitrate and cerium nitrate concentrations of 0.5mol / L each) for use;

[0040] (2) Next, repeatedly dip 2g of MCM-41 into 50mL of a mixed solution of copper nitrate, manganese nitrate and cerium nitrate (40g / L) and stir for 6h, then filter and dry;

[0041] (3) Next, place the sample obtained in step (2) in a muffle furnace and calcinate at 400°C for 6 hours to obtain a heterogeneous Cu-Mn-Ce-based Fenton catalyst;

[0042] (4) Then, add 0.4 g / L heterogeneous Cu-Mn-Ce Fenton catalyst and 0.8 mol / L hydrogen peroxide to the 1500 mg / L high-concentration rhodamine B solution, adjust the pH to 5, and heat the solution to 80 ℃, let the system react for 210min, the results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com