Polypropylene synthetic paper and production method thereof

A polypropylene synthetic paper, polypropylene technology, applied in synthetic resin layered products, chemical instruments and methods, layered products, etc., can solve the problems of surface flatness, thickness uniformity, thickness controllable range, light transmittance and moisturizing Wet tension has not been improved, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

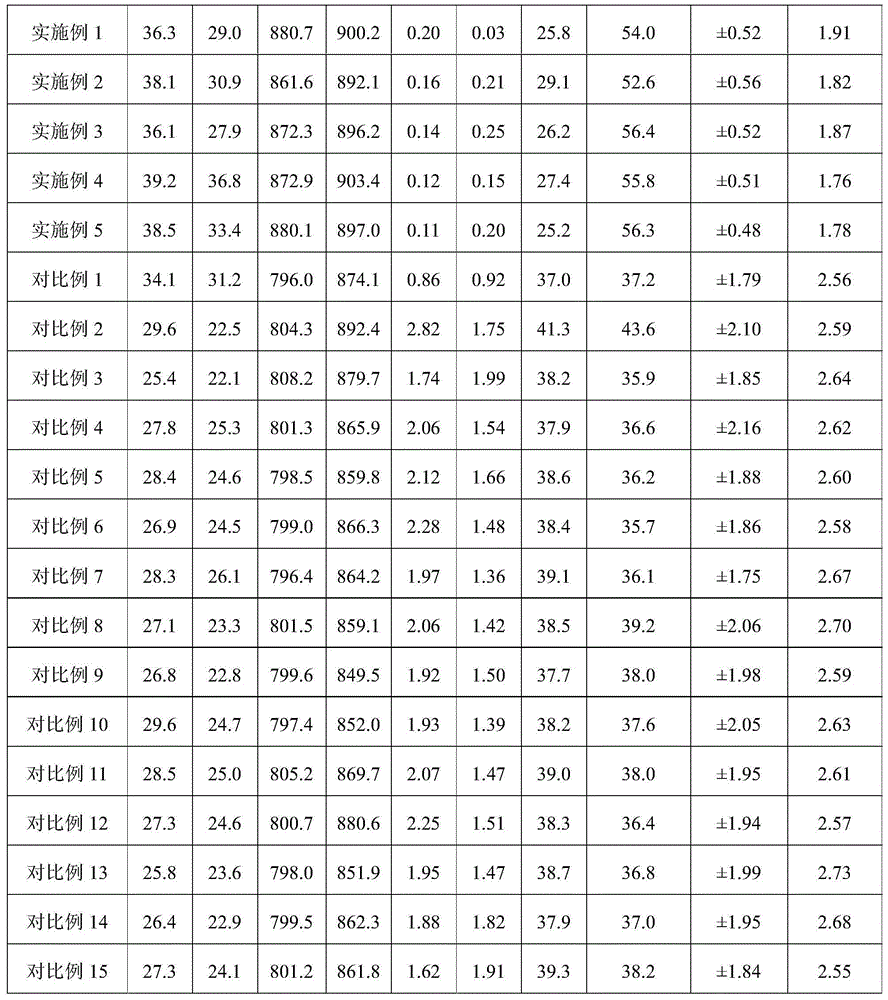

Embodiment 1

[0063] Taking the total thickness of the polypropylene synthetic paper as 100%, the polypropylene synthetic paper of the present embodiment has a thickness ratio of:

[0064] Outer layer: 60%, middle layer: 10% and inner layer: 30%;

[0065] Wherein, the sum of all raw material weights of each layer is respectively 100wt%, the outer layer raw material is: (1#42wt%+6#25wt%+4#33wt%), the middle layer raw material is: (2#46wt%) +4#41wt%+5#13wt%) and the inner surface layer raw material is: (1#25wt%+6#42wt%+4#33wt%).

[0066] The present embodiment adopts following steps to carry out the preparation of polypropylene synthetic paper:

[0067] (1) The raw material for the outer layer, the raw material for the middle layer and the raw material for the inner layer are respectively extruded through the extruder, the extrusion temperature of the raw material for the outer layer and the raw material for the inner layer is 190°C, and the extrusion temperature for the raw material for the...

Embodiment 2

[0072] Taking the total thickness of the polypropylene synthetic paper as 100%, the polypropylene synthetic paper of the present embodiment has a thickness ratio of:

[0073] Outer layer: 5%, middle layer: 80% and inner layer: 15%;

[0074]Wherein, the sum of all raw material weights of each layer is respectively 100wt%, and the outer layer raw material is: (1#28wt%+6#42wt%+4#30wt%), the middle layer raw material is: (2#50wt%+ 4#50wt%) and the raw material of the inner surface layer is: (1#42wt%+6#35wt%+4#23wt%).

[0075] The present embodiment adopts following steps to carry out the preparation of polypropylene synthetic paper:

[0076] (1) The raw material for the outer layer, the raw material for the middle layer and the raw material for the inner layer are respectively extruded through the extruder, the extrusion temperature of the raw material for the outer layer and the raw material for the inner layer is 230°C, and the extrusion temperature for the raw material for the...

Embodiment 3

[0081] Taking the total thickness of the polypropylene synthetic paper as 100%, the polypropylene synthetic paper of the present embodiment has a thickness ratio of:

[0082] Outer layer: 32%, middle layer: 45% and inner layer: 27%;

[0083] Wherein, the sum of all raw material weights of each layer is respectively 100wt%, and the outer layer raw material is: (1#25wt%+6#25wt%+4#50wt%), the middle layer raw material is: (2#50wt%+ 3#50wt%) and the raw material of the inner surface layer is: (1#42wt%+6#25wt%+4#33wt%).

[0084] The present embodiment adopts following steps to carry out the preparation of polypropylene synthetic paper:

[0085] (1) The raw material for the outer layer, the raw material for the middle layer and the raw material for the inner layer are respectively extruded through the extruder, the extrusion temperature of the raw material for the outer layer and the raw material for the inner layer is 210°C, and the extrusion temperature for the raw material for t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com