Degradable hydrate generating accelerant and preparation method thereof

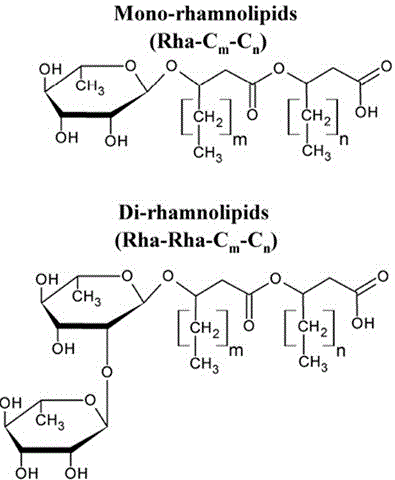

A technology of hydrate formation and accelerator, which is applied in the field of degradable hydrate formation accelerator and its preparation, can solve the problems of large environmental pollution and high cost, achieve good effect, promote foam generation, and reduce surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

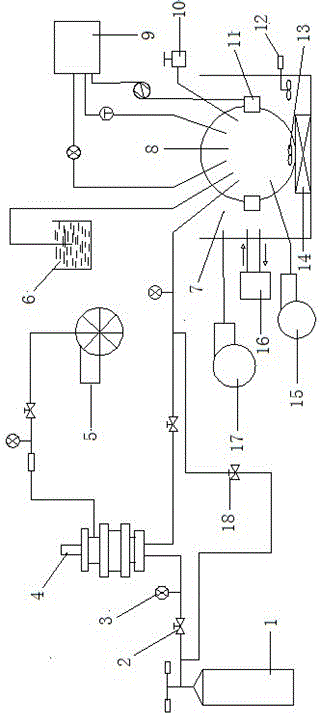

[0037] Configure a composite accelerator solution with a mass concentration of 0.03% rhamnolipid + 0.03% lignin + 0.015% sodium bicarbonate, inject 170 ml into the reaction kettle, set the temperature of the constant temperature water bath, the given initial temperature is 2.5 °C, and the experimental gas is 99.9% CO 2 Gas, inhale after the temperature is stable, turn on the stirrer in the kettle 10 minutes after the inflow is completed, the stirring speed is maintained at 1450r / min, and the reaction kettle is filled with hydrate for 180 minutes and the pressure is no longer reduced, which is shorter than the reaction time when there is no additive in the same system 21.8%, and the phase equilibrium pressure measured by constant temperature pressure search method is 2.45Mpa.

[0038] Specific steps are as follows:

[0039] Prepare the solution: Use an electronic balance with an accuracy of 0.001g to accurately weigh the reagents and configure the reaction solution of the corr...

Embodiment 2

[0045] A composite accelerator solution with a mass concentration of 0.05% rhamnolipid + 0.05% lignin + 0.02% sodium bicarbonate was prepared, 170 ml was injected into the reaction kettle, and the temperature of the constant temperature water bath was set. The given initial temperature was 2.5 °C, and the experimental gas was 99.9% CO 2 Gas, inhale after the temperature is stable, turn on the stirrer in the kettle 10 minutes after the gas intake is completed, the stirring speed is maintained at 1450r / min, and the reaction kettle is filled with hydrate for 170min and the pressure is no longer reduced, which is shorter than the reaction time when there is no additive in the same system 26.1%, using the constant temperature pressure search method, the phase equilibrium pressure is 2.4Mpa.

Embodiment 3

[0047] Configure a composite accelerator solution with a mass concentration of 0.07% rhamnolipid + 0.07% lignin + 0.025% sodium bicarbonate, inject 170 ml into the reaction kettle, set the temperature of the constant temperature water bath, the given initial temperature is 2.5 °C, and the experimental gas is 99.9% CO 2 Gas, inhale after the temperature is stable. After 10min of air intake, the stirring speed of the agitator in the kettle is maintained at 1450r / min. After 140min of reaction, the reaction kettle is filled with hydrate and the pressure is no longer reduced. The reaction time is shortened by 39.1% compared with the same system without additives. %, using the constant temperature pressure search method, the phase equilibrium pressure is 2.38Mpa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com