Pretreatment method of high-concentration cutting fluid sewage

A cutting fluid and high-concentration technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, metallurgical wastewater treatment, etc., can solve the problem of destabilization and oil removal, micro-electrolysis scaling and silting failure , Difficult long-term stability, effective handling and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

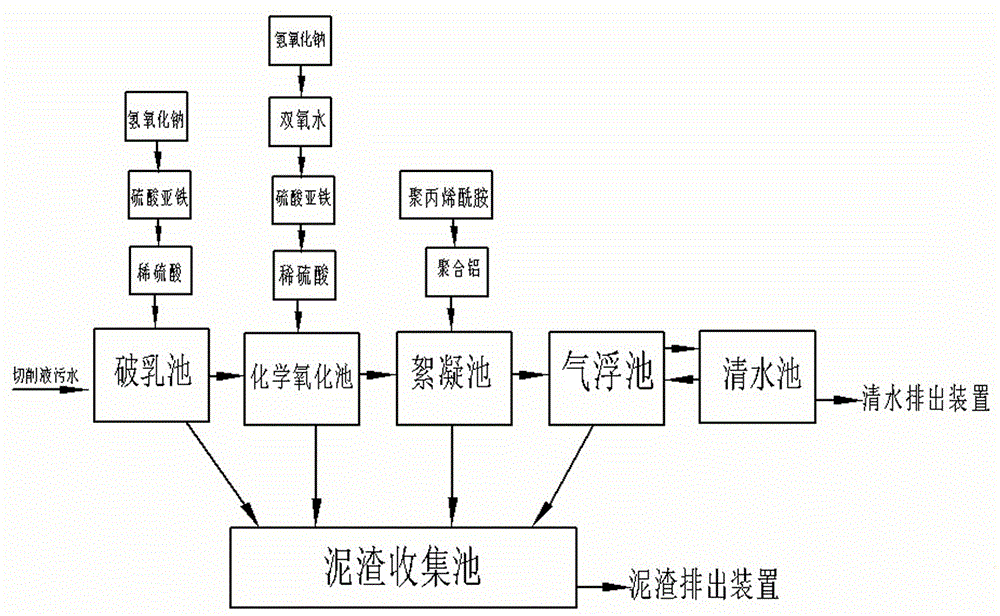

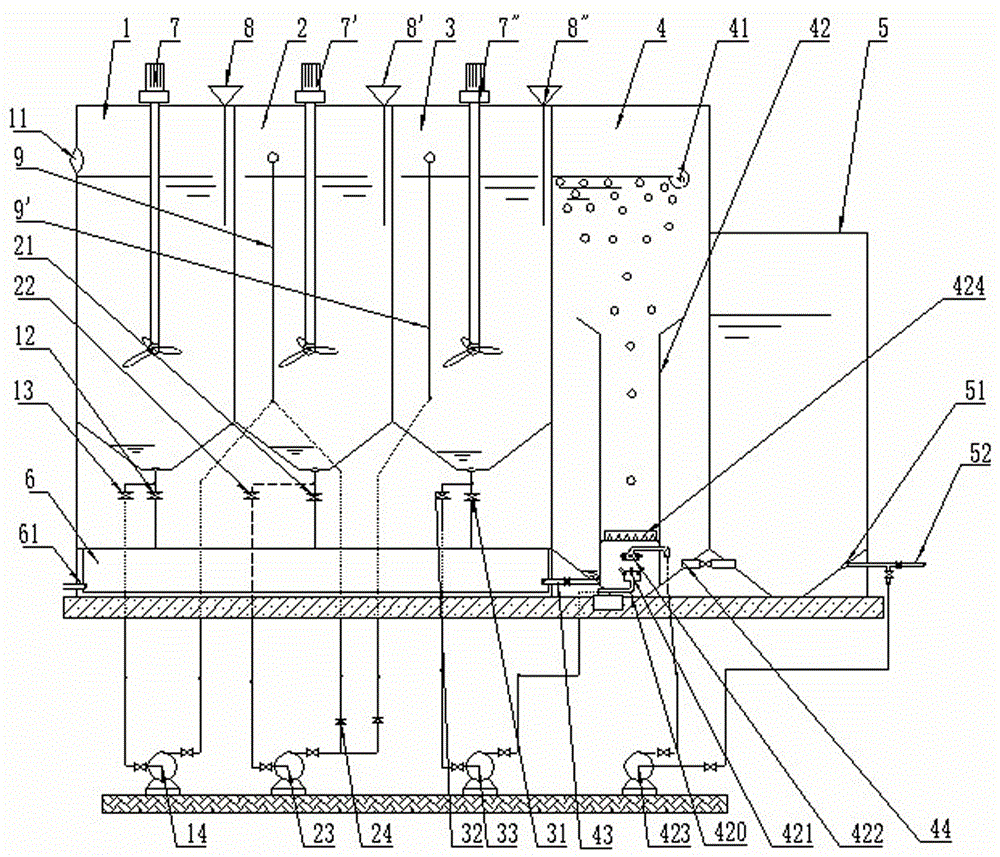

[0012] Below in conjunction with accompanying drawing, the pretreatment method of high-concentration cutting fluid sewage of the present invention is further described;

[0013] Depend on figure 1 , figure 2 Visible, the pretreatment method of high-concentration cutting fluid sewage of the present invention, comprises the following steps:

[0014] a. Inject the high-concentration cutting fluid sewage into the demulsification tank 1 through the water inlet 11. After reaching the normal liquid level, start the first vertical mixer 7 to make the sewage in a turbulent state, and then carry out the treatment through the first long-handle dosing funnel 8. Dosing: first add dilute sulfuric acid, adjust the pH of the cutting fluid sewage to 5, and react for 20 minutes; then add ferrous sulfate solution to the sewage at a weight ratio of 2‰ of the chemical to the sewage for demulsification reaction; 30-40 minutes Finally, add NaOH solution with a weight concentration of 10%, and adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com