Comprehensive treatment method for tungsten smelting wastewater

A comprehensive wastewater treatment technology, applied in metallurgical wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as unsatisfactory effect, heavy odor, and unresolved wastewater treatment problems , to achieve the effects of reducing equipment and facility investment and operating cost consumption, shortening the treatment process, and improving wastewater treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

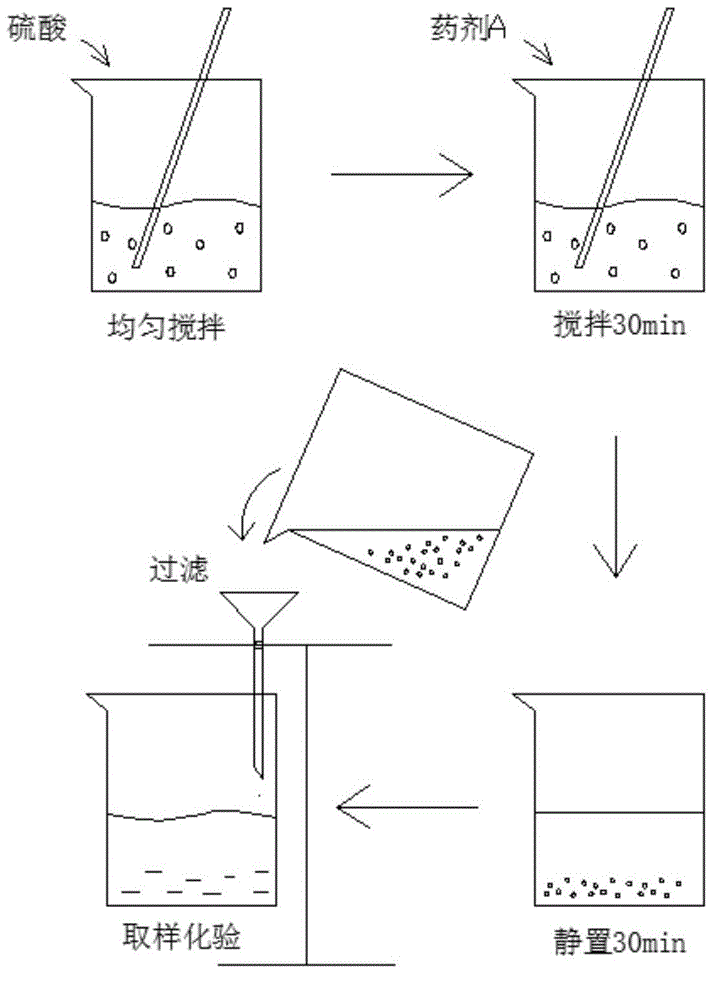

[0034] Example 1: 300ml of waste water, containing 15 mg / l of ammonia nitrogen, 500 mg / l of COD, and 8 mg / l of As in the waste water, adding sulfuric acid to adjust pH=4. Weigh 2.5g of drug A, add it to the waste water, stir for 30min, let the drug A fully dissolve and react, let it stand for 30min, filter it with filter paper, take samples to test ammonia nitrogen, COD, As, the content after treatment is yes, ammonia nitrogen is 0.18mg / l, COD is 76mg / l, As is 0.06mg / l, and the removal rates of the three pollution factors are ammonia nitrogen removal rate of 98.8%, COD removal rate of 84.8%, As removal rate of 99.3%, available chlorine in bleaching powder The effective utilization rate is 78.7%.

Embodiment 2

[0035] Example 2: 300ml of waste water containing 500 mg / l of ammonia nitrogen, 100 mg / l of COD and 50 mg / l of As in the waste water, adding sulfuric acid to adjust pH=6. Weigh 4.5g of medicament A, add it to waste water, stir for 30min to fully dissolve the medicament A, let it stand for 30min, filter it with filter paper, take a sample to test ammonia nitrogen, COD, As, the content of ammonia nitrogen after treatment is 6.37mg / l. COD is 50mg / l, As is 0.36mg / l, and the removal rates of the three pollution factors are ammonia nitrogen removal rate of 98.7%, COD removal rate of 50%, As removal rate of 99.3%, and available chlorine in bleaching powder The effective utilization rate is 88%.

Embodiment 3

[0036] Example 3: 300 ml of waste water, containing 150 mg / l of ammonia nitrogen, 150 mg / l of COD, and 0.5 mg / l of As in the waste water, adding sulfuric acid to adjust the pH to 7. Weigh 1.8g of medicament A, add it to the waste water, stir for 30min, let the medicament A fully dissolve and react, let it stand for 30min, filter with filter paper, take a sample to test ammonia nitrogen, COD, As, and the content of ammonia nitrogen after treatment is 6.5mg / l , COD is 45mg / l, As is 0.016mg / l, and the removal rates of the three pollution factors are ammonia nitrogen removal rate of 95.7%, COD removal rate of 70%, As removal rate of 96.8%. was 86.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com