Biogas slurry deep treatment method and application

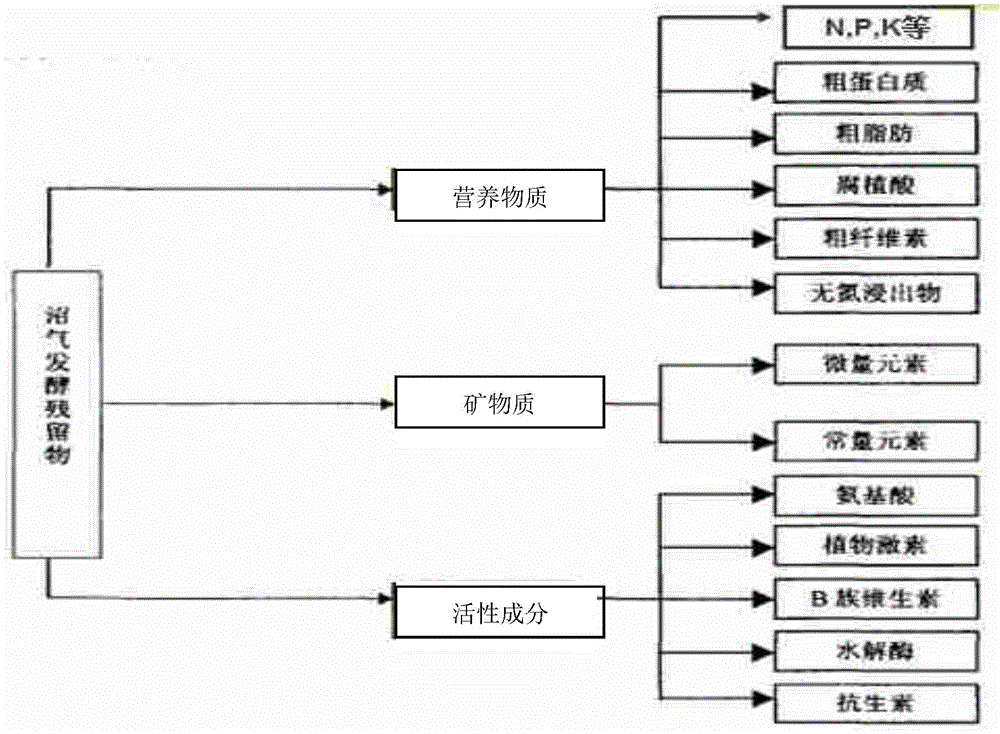

A treatment method and technology for biogas slurry, applied in the field of deep treatment of biogas slurry, can solve problems such as environmental pollution, waste, and inability to reflect the value of nutrients, and achieve simple process flow, loose storage conditions, and flexible control of multi-effect evaporation. The effect of concentration multiples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

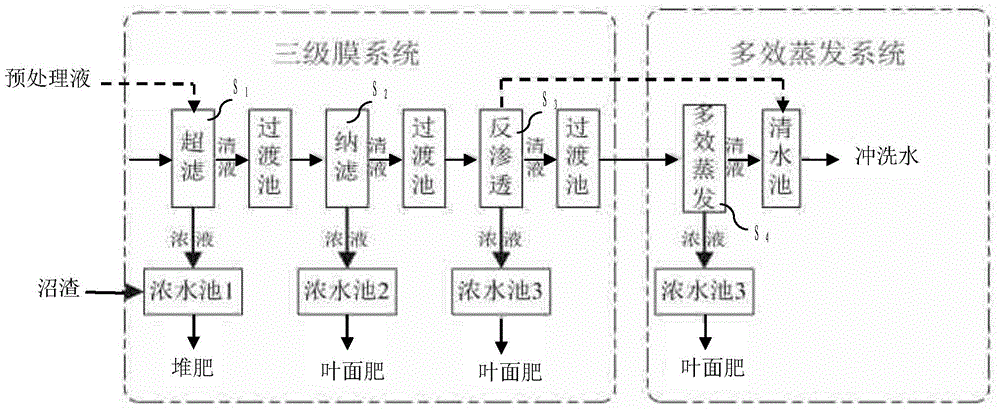

[0024] The biogas slurry deep treatment method of the present invention is mainly through the three-stage membrane system and the multi-effect evaporation system S 4 To be done. Among them, the three-stage membrane system includes ultrafiltration S 1 , nanofiltration S 2 and reverse osmosis system S 3 . Among them, a transition pool is set behind each stage of the membrane system to temporarily store the clear liquid filtered by the membrane system, and each stage of the membrane system and the multi-effect evaporation system are also connected to concentrated water pools 1-4 respectively.

[0025] Such as figure 1 As shown, the method for preparing foliage fertilizer by biogas slurry deep treatment specifically includes the following steps:

[0026] (1) Ultrafiltration: The biogas slurry after pretreatment flows in the tube side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com