A kind of phase change energy storage aggregate and preparation method thereof

A technology of phase change energy storage and phase change materials, which is applied in the field of phase change energy storage aggregate and its preparation, can solve the problems of occupying large land, endangering resources, waste, etc., and achieve a phase change energy storage with good effect and high strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

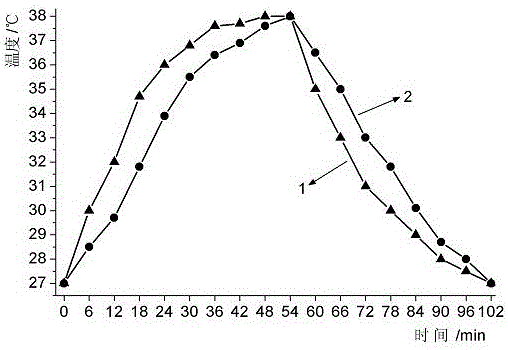

Image

Examples

Embodiment 1

[0024] Put a sufficient amount of phase change material with a phase change temperature of 25.7°C (the weight ratio is liquid paraffin:paraffin wax=85:15, and the phase change enthalpy is 105.1J / g) into the container, and heat up to melt the phase change material; Add 10 parts of waste aerated concrete particles with a particle size of 2-7 mm, stir evenly, seal the container, and absorb for 2 hours under a vacuum of 0.06 MPa to make a phase change material core.

[0025] Sodium methyl siliconate emulsion, steel slag powder (the specific surface area is 417m 2 / kg), 32.5# ordinary Portland cement and water to make a mixed slurry according to the mass ratio of 2.7:5.5:1.2:2; building gypsum and manganese slag powder (specific surface area is 532m 2 / kg) to make mixed powder according to the mass ratio of 1.5:3.8. Immerse the core of the phase change material in the mixed slurry for 4 seconds, take it out and wrap a layer of the mixed powder on the outside; keep it for 28 days n...

Embodiment 2

[0027] Put a sufficient amount of phase change material with a phase change temperature of 29.3°C (liquid paraffin:stearic acid=78:22 by weight, phase change enthalpy is 135.2J / g) into the container, heat up to melt the phase change material Add 10 parts of waste aerated concrete particles with a particle size of 2-7 mm, stir evenly, seal the container, and absorb for 2 hours under a vacuum of 0.08 MPa to make a phase change material core.

[0028] White latex, steel slag powder (the specific surface area is 453m 2 / kg), 32.5# fly ash portland cement and water to make a mixed slurry according to the mass ratio of 2.2:5:1.5:2.2; building gypsum and manganese slag powder (specific surface area is 516m 2 / kg) to make mixed powder according to the mass ratio of 1.7:3.5. Immerse the core of the phase change material in the mixed slurry for 6 seconds, take it out, and then wrap a layer of the mixed powder on its outside; keep it for 28 days naturally to obtain the phase change ener...

Embodiment 3

[0030] Put a sufficient amount of phase change material with a phase change temperature of 35.2°C (liquid paraffin: butyl stearate = 75:25 by weight, phase change enthalpy is 143.2J / g) into the container, and raise the temperature to make the phase change The material is melted; 10 parts of waste aerated concrete particles with a particle size of 2-7 mm are added, stirred evenly, the container is sealed, and adsorbed for 2 hours under a vacuum of 0.07 MPa to make a phase change material core.

[0031] Sodium methyl siliconate emulsion, white latex, steel slag powder (the specific surface area is 485m 2 / kg), 32.5# slag salt cement and water to make a mixed slurry according to the mass ratio of 1:0.7:4.5:1.8:2.5; building gypsum and manganese slag powder (specific surface area is 464m 2 / kg) to make mixed powder according to the mass ratio of 2:3. Immerse the core of the phase change material in the mixed slurry for 8 seconds, take it out and wrap a layer of the mixed powder on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com