Method for enabling metal surface to penetrate nano powder by laser-induced impact

A metal surface, laser-induced technology, applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of complex operation process, shedding, strict requirements on the shape and size of the test piece, etc., and achieve low cost and easy operation. The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The base metal in this example is: 6082 aluminum alloy (200mm×100mm×3mm), which is mechanically polished, then cleaned with 75% alcohol, dried for later use, and the nanoparticles are nickel alloy;

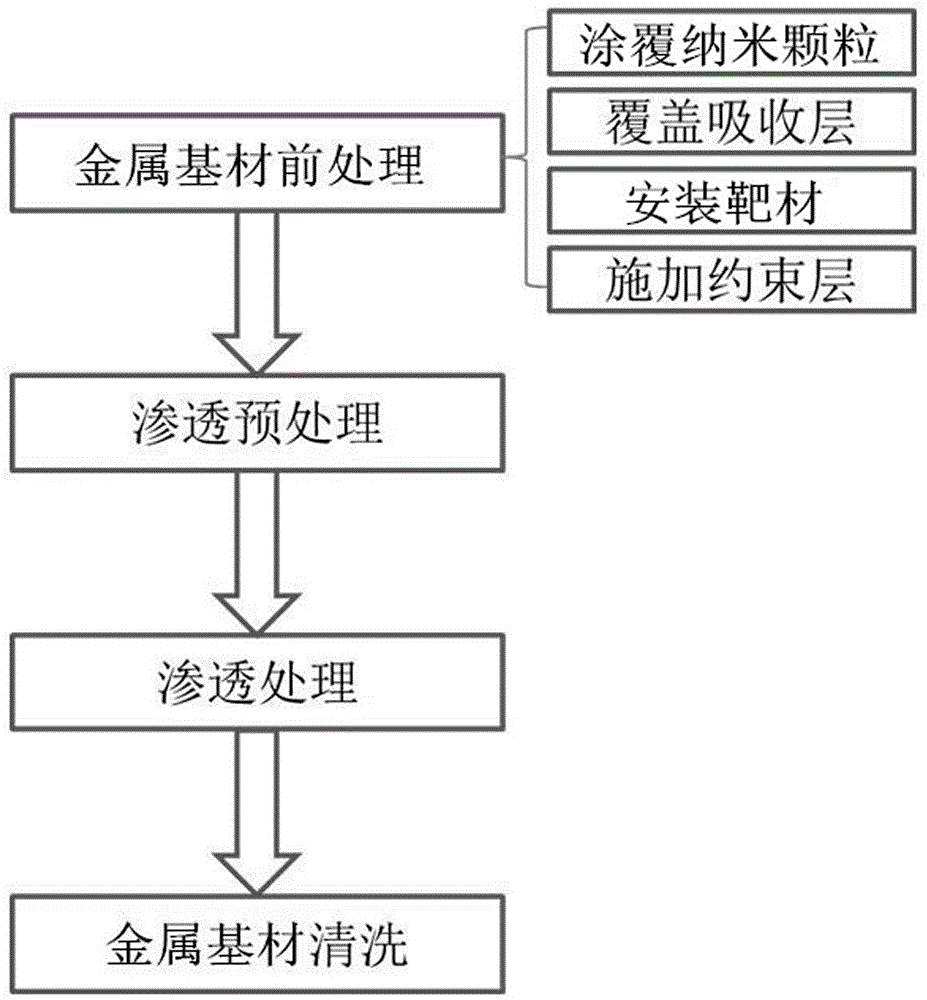

[0026] This embodiment proceeds according to the following steps:

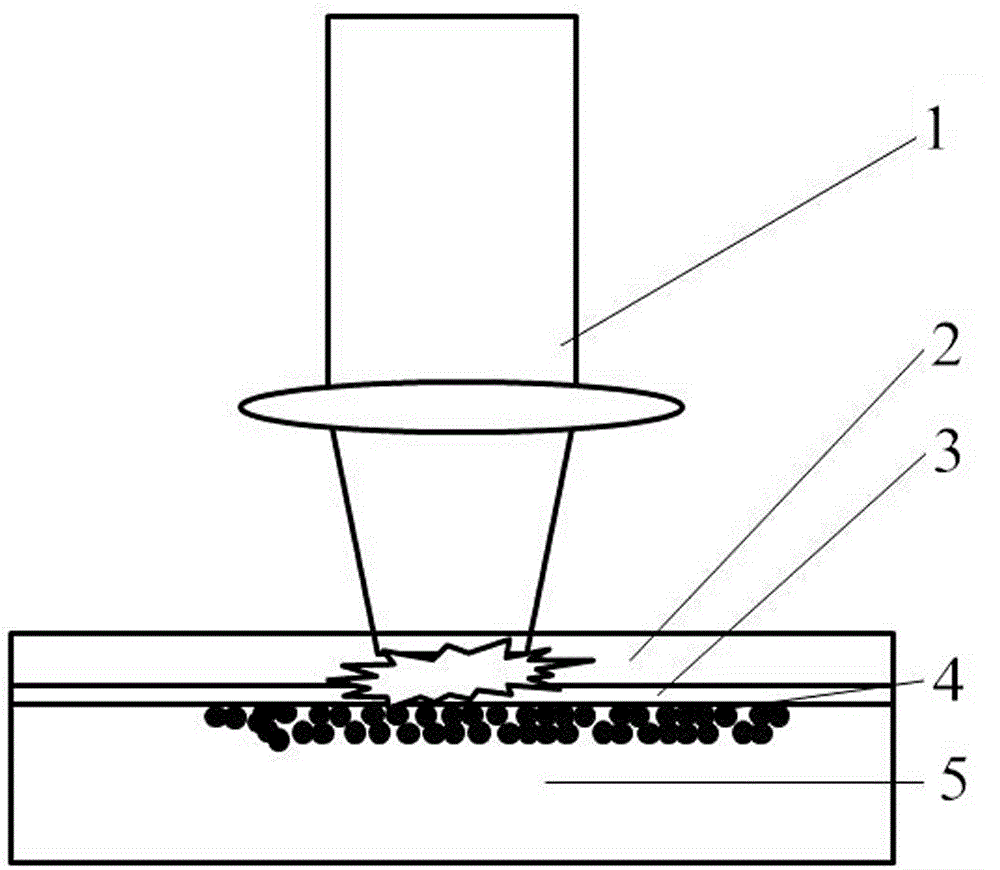

[0027] (1) In the clean room, coat the surface of the absorbing layer to form a 0.1mm thick nanoparticle coating layer, and cover the above absorbing layer on the working end surface of the target;

[0028] (2) Install the working end surface of the target covered with the absorbing layer on the workbench, and apply a constrained layer with a thickness of 1mm on the absorbing layer;

[0029] (3) Face the metal surface of the substrate to be treated to the laser beam, and perform pre-infiltration treatment with a laser beam with a laser pulse width of 20ns, a laser wavelength of 1064nm, a laser beam diameter of 5mm, a laser energy of 1J, and a repetition rate of 2Hz. Among them, the overlapping rate is ...

Embodiment 2

[0034] The base metal in this example is TC4 titanium alloy (100mm×100mm×2mm), after mechanical polishing, then the surface is cleaned with 75% alcohol, dried for later use, and the nano metal particles are tungsten carbide;

[0035] This embodiment proceeds according to the following steps:

[0036] (1) In the clean room, coat the surface of the absorbing layer to form a 0.1mm thick nanoparticle coating layer, and cover the above absorbing layer on the working end surface of the target;

[0037] (2) Install the working end surface of the target covered with the absorbing layer on the workbench, and apply a constrained layer with a thickness of 2mm on the absorbing layer;

[0038] (3) Face the metal surface of the base material to be treated to the laser beam, and perform pre-infiltration treatment with a laser beam with a laser pulse width of 40ns, a laser wavelength of 1064nm, a laser beam diameter of 3mm, a laser energy of 5J, and a repetition rate of 2Hz. Among them, the ...

Embodiment 3

[0043]The base metal in this example is: 6082 aluminum alloy (200mm×100mm×3mm), which is mechanically polished, then cleaned with 75% alcohol, dried for later use, and the nanoparticles are nickel alloy;

[0044] This embodiment proceeds according to the following steps:

[0045] (1) In the clean room, coat the surface of the absorbing layer to form a 0.1mm thick nanoparticle coating layer, and cover the above absorbing layer on the working end surface of the target;

[0046] (2) Install the working end surface of the target covered with the absorbing layer on the workbench, and apply a constrained layer with a thickness of 3 mm on the absorbing layer;

[0047] (3) Face the metal surface of the substrate to be treated to the laser beam, and perform pre-infiltration treatment with a laser beam with a laser pulse width of 30ns, a laser wavelength of 1064nm, a laser beam diameter of 2mm, a laser energy of 3J, and a repetition rate of 2Hz. Among them, the overlapping rate is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com