Preparation method of diamond heat sink piece

A diamond and heat sink technology, applied in metal material coating process, gaseous chemical plating, coating and other directions, can solve the problems of low thermal conductivity, slow diamond growth rate, rough surface, etc., achieve uniform growth, improve The effect of heat dissipation and increasing growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

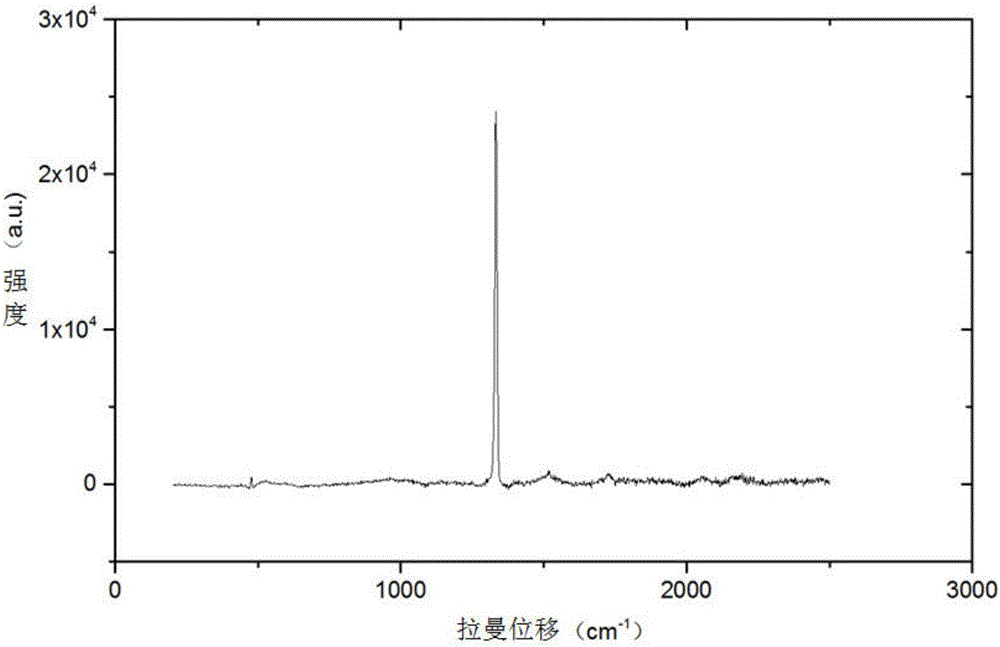

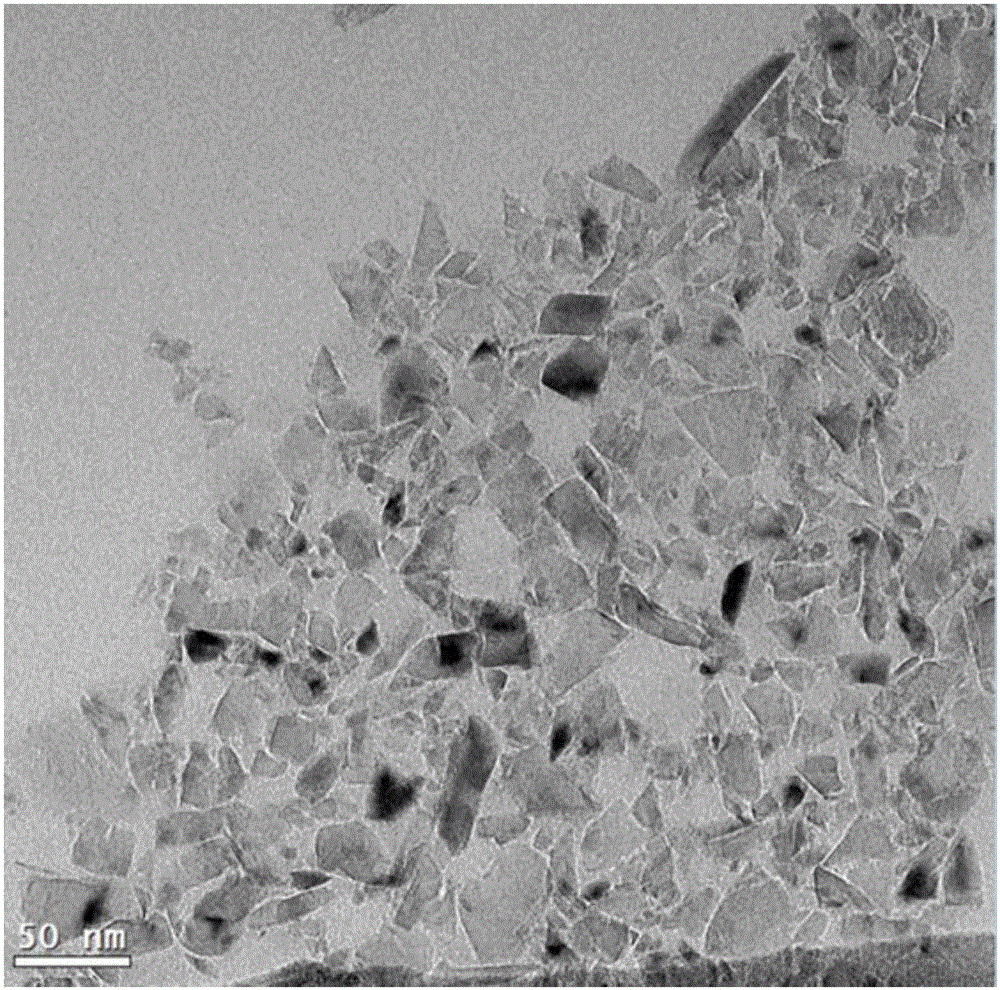

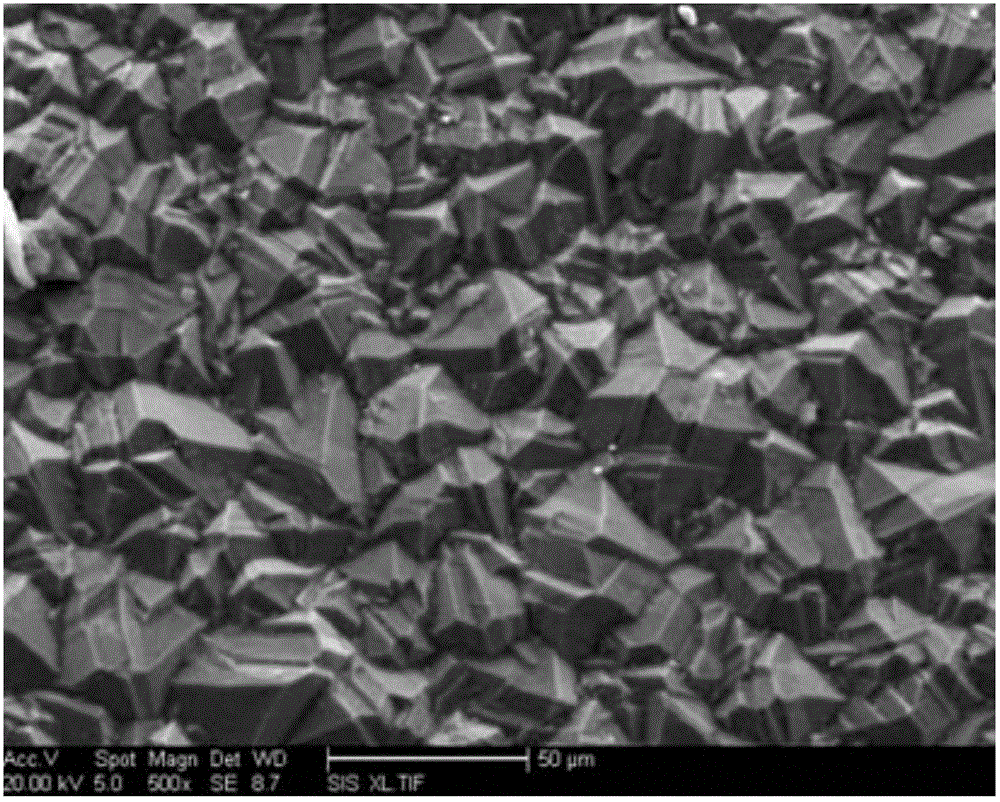

[0024] Specific implementation mode 1: The preparation method of the diamond heat sink of this embodiment is implemented in the following steps:

[0025] 1. Perform wire cutting on the silicon wafer, and then place it in absolute ethanol and deionized water for ultrasonic cleaning to obtain a clean silicon wafer substrate;

[0026] 2. Uniformly coat nano-diamond suspension on the surface of a clean silicon wafer substrate to obtain a silicon wafer coated with diamond suspension;

[0027] 3. Place the silicon wafer coated with diamond suspension obtained in step 2 in a MWCVD (plasma assisted chemical vapor deposition) device, and pump the vacuum of the vacuum chamber to 3×10 -6 Below Pa, pass in hydrogen and methane, control the hydrogen flow rate from 150 to 500 sccm, and the methane flow rate from 3 to 30 sccm. The silicon wafer coated with diamond suspension is heated to 700 to 1100°C and then chemical vapor deposition is performed, and the silicon substrate is taken out. Diamond h...

specific Embodiment approach 2

[0034] Specific embodiment two: this embodiment is different from specific embodiment one in that in step one, ultrasonic cleaning is performed for 15-30 minutes under the condition of an ultrasonic power of 300-600W. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0035] Embodiment 3: This embodiment is different from Embodiment 1 or 2 in that the particle size of nanodiamonds in the nanodiamond suspension described in step 2 is 5-50 nanometers. Other steps and parameters are the same as those in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com