A structure-controllable brush-type multi-quaternary ammonium salt antibacterial agent and its preparation method

A technology of multiple quaternary ammonium salts and antibacterial agents, applied in the field of quaternary ammonium salt antibacterial agents, can solve the problems of complex preparation methods of antibacterial agents, and achieve good water solubility, prevent bacterial growth, and good antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Add 40.0g (0.095 mole) AG80 and 60g (0.57 mole) diethanolamine into a 250ml round bottom flask, and at a reaction temperature of 90°C, the reaction time is 5h to obtain the first step product - modified AG80, after decompression Distillation and vacuum oven drying to obtain pure modified AG80;

[0025] Take 5.6g (0.0066 moles) of modified AG80 and add 10g (0.08 moles) of benzyl chloride, and react dropwise at 80°C for 12 hours to obtain the final product brush-shaped structure multi-quaternary ammonium salt antibacterial agent, which is subjected to vacuum distillation, drying, etc. After the procedure, pure brush-shaped structure polyquaternary ammonium salt antibacterial agent S-1 is obtained, and its degree of quaternization is 98.9%.

Embodiment 2

[0027] Add 40.0g (0.095 mole) AG80 and 60g (0.57 mole) diethanolamine into a 250ml round bottom flask, and at a reaction temperature of 80°C, the reaction time is 4h to obtain the first step product - modified AG80, after decompression Distillation and vacuum oven drying to obtain pure modified AG80;

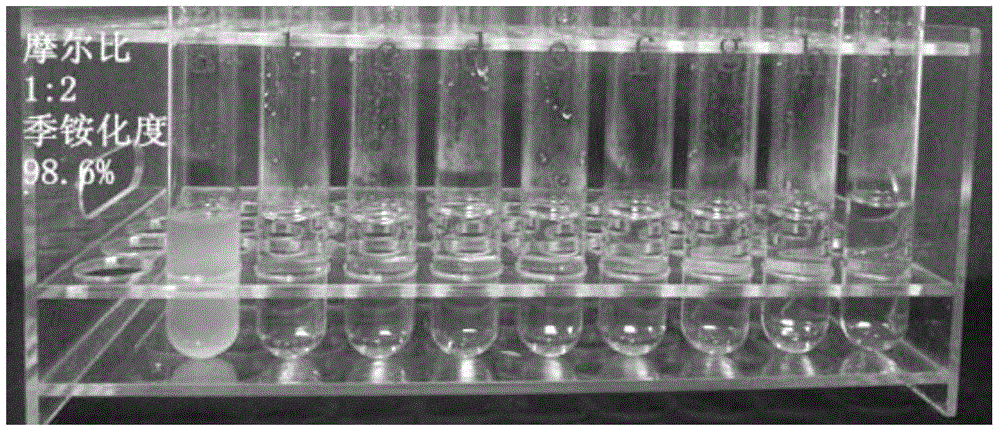

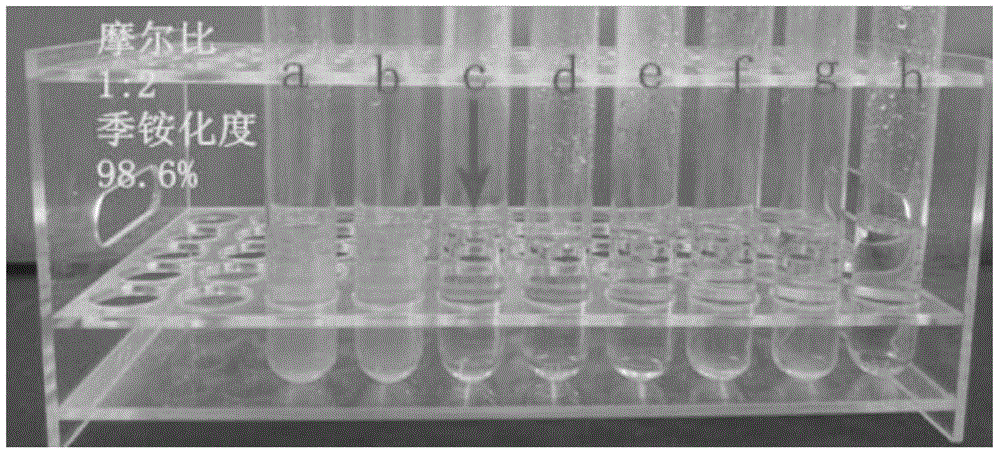

[0028] Take 11g (0.013 moles) of modified AG80 and add 10g (0.08 moles) of benzyl chloride, and react dropwise at 90°C for 14 hours to obtain the final product-brush-shaped structure multi-quaternary ammonium salt antibacterial agent, which is subjected to vacuum distillation and drying. Obtain pure brush-type structure polyquaternary ammonium salt antibacterial agent S-2 after the procedure, and its degree of quaternization is 80.5%.

Embodiment 3

[0030] Add 40.0g (0.095 mole) AG80 and 60g (0.57 mole) diethanolamine into a 250ml round bottom flask, and at a reaction temperature of 100°C, the reaction time is 7h to obtain the first step product - modified AG80, after decompression Distillation and vacuum oven drying to obtain pure modified AG80;

[0031] Take 14g (0.017 moles) of modified AG80 and add 10g (0.08 moles) of benzyl chloride, and react dropwise at 95°C for 13 hours to obtain the final product-a multi-quaternary ammonium antibacterial agent with a brush structure, which is distilled under reduced pressure, dried, etc. After the procedure, pure brush-type structure polyquaternary ammonium salt antibacterial agent S-3 is obtained. Its degree of quaternization is 63.8%.

[0032] The multi-quaternary ammonium salt antibacterial agents with brush structure prepared by the above method all have good water solubility.

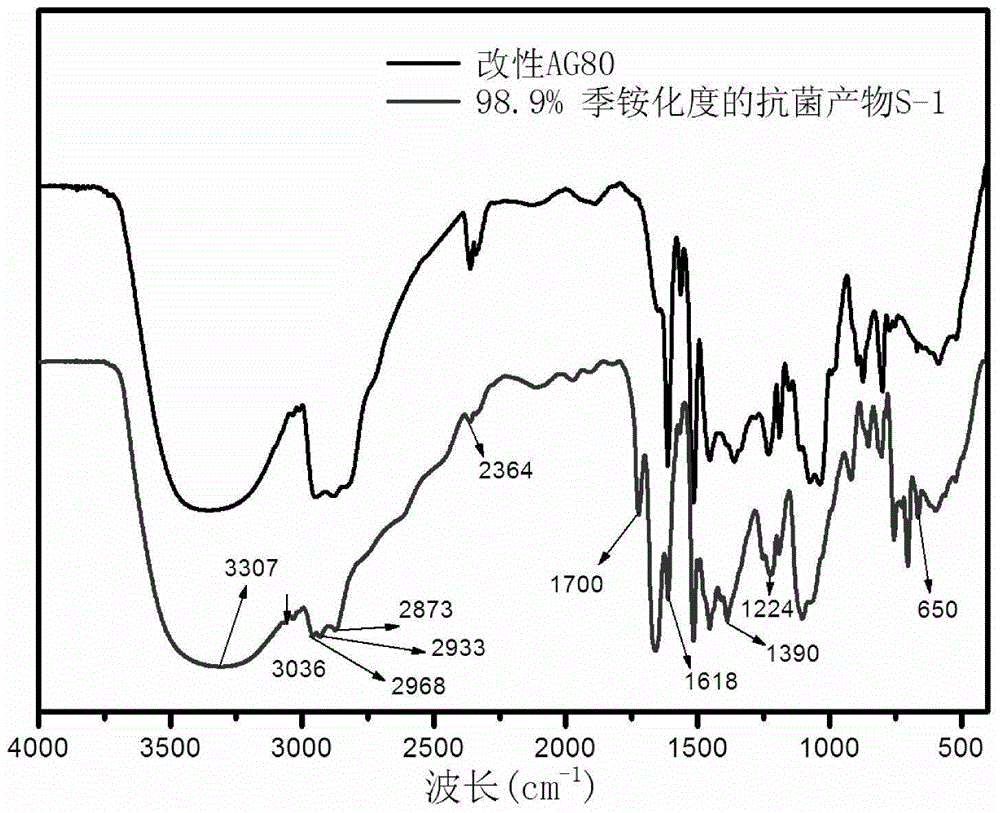

[0033] The molecular structure of the modified AG80 obtained in the above embodiment 1 and the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com