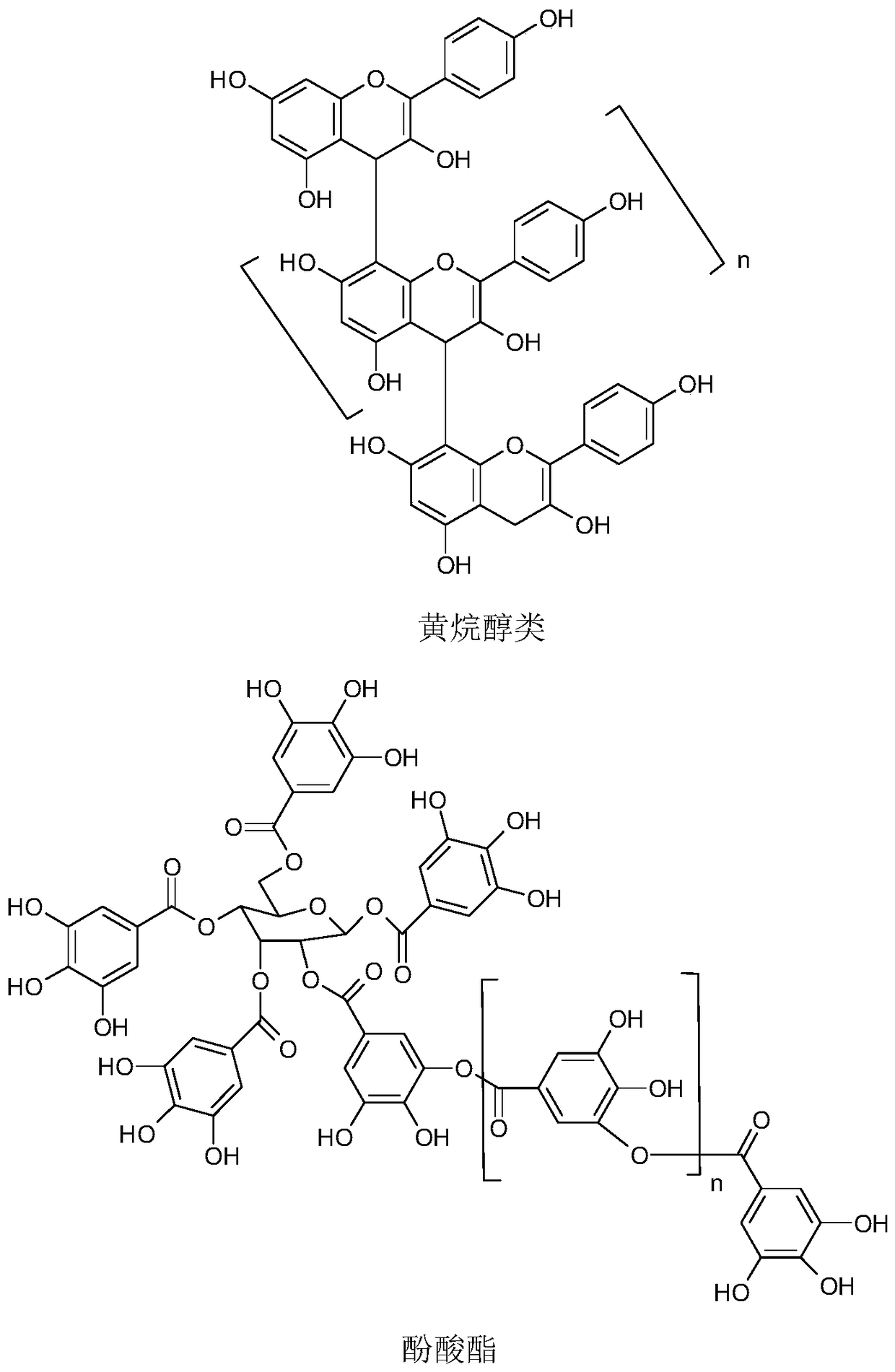

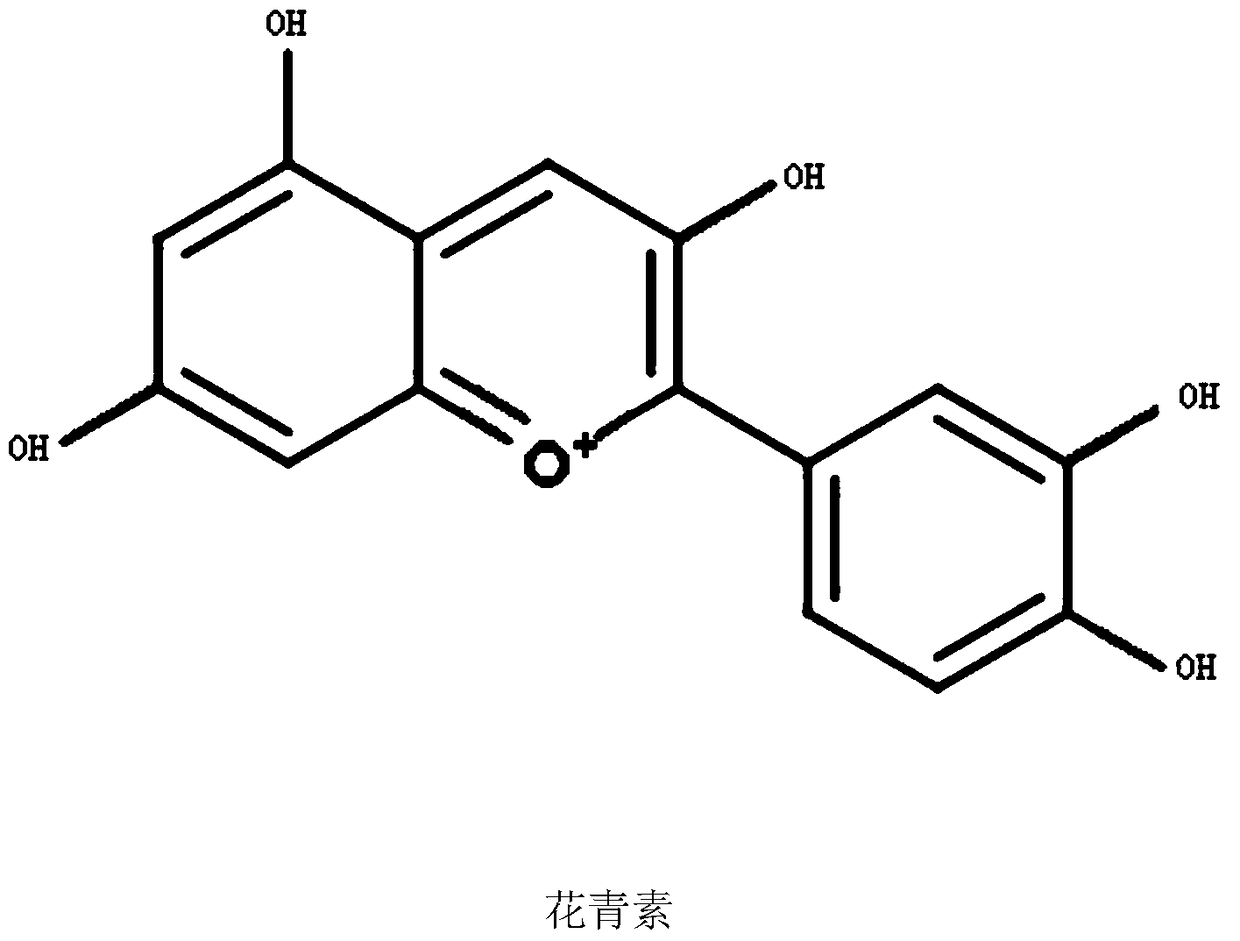

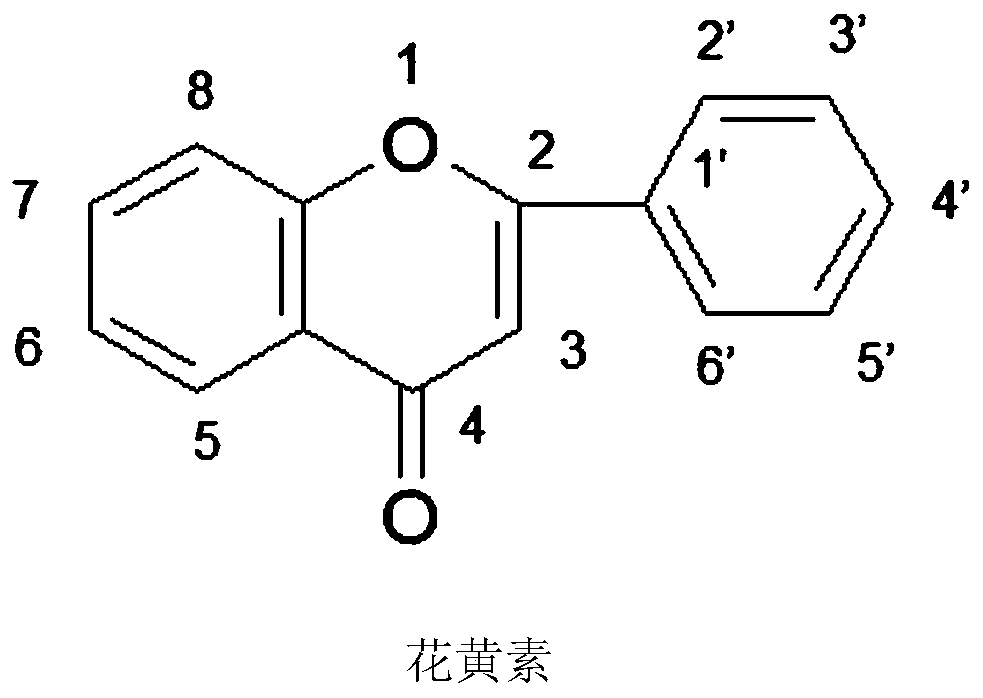

Sugarcane bioactive ingredient composition, functional health food and preparation method thereof

A bioactive ingredient, health food technology, applied in food extraction, food ingredients, food science and other directions, can solve the problems of brown sugar with many harmful impurities, white sugar without nutrition, loss of beneficial substances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0132] Extraction of sugarcane polyphenols extract:

[0133] Step 1: Remove impurities such as old leaves and soil from the sugarcane tips and blanch to kill enzymes. The blanching temperature is 80°C, and water is used as the blanching liquid. The blanching time is 2 minutes: immerse the blanched sugarcane tips in ice In the water mixture, the temperature of the sugarcane tip is lowered to below 8°C; the cooled sugarcane tip is immediately drained to prevent residual water from entering the extraction process and causing errors. Cut into small pieces, put them into a crusher, and extract the broken sugarcane tips with ethanol at a temperature of 60°C. The extraction time is 2 hours, the extract is combined with the juice extruded from sugarcane shoots, filtered, heated to concentrate the combined juice, the obtained concentrate is crude polyphenols, the volatilized organic solvent is recovered, and the polyphenol content is determined by the Folin method. The determination m...

preparation example 2

[0137] Extraction of sugarcane flavonoids extract:

[0138] 100 g of sugarcane tip raw material after chopping use 60% ethanol to extract 2 times ultrasonically with the solid-liquid ratio impregnation method of 1: 15 (mass volume ratio), each 1 hour, extracting solution merges, decompression (pressure<0.09MPa ) concentrated to obtain raw material extract. Then the raw material extract is passed through a chromatographic column filled with D101 macroporous adsorption resin, and sugar and other water-soluble impurities are washed off with pure water. , after washing off sugar and other water-soluble impurities with pure water, then use the ethanol-water solution with a volume percentage concentration of 60% to carry out gradient elution, collect the eluent with a volume percentage concentration of 60%, and decompress (pressure<0.09 MPa) concentrated, use alkaline solution to adjust the pH value of the concentrated eluent to be 10, then extract 2 times with 2 times the volume o...

Embodiment 1

[0140] Nutritious sucrose containing octacosanol, sugarcane polyphenols extract and sugarcane flavonoids extract: 40mg of octacosanol (nominal content 50%), 30mg of sugarcane polyphenols extract and sugarcane flavonoids Mix 20 mg of sucrose, add sucrose to 98g, grind into fine powder, mix evenly, and then sterilize, and pack the fine powder in bags, which is No. 2 nutritional sucrose.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com