Plant enzyme solid preparation and preparation method thereof

A solid preparation, plant enzyme technology, applied in the field of enzyme processing, can solve problems such as waste, achieve the effect of being convenient to carry and promote intestinal health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

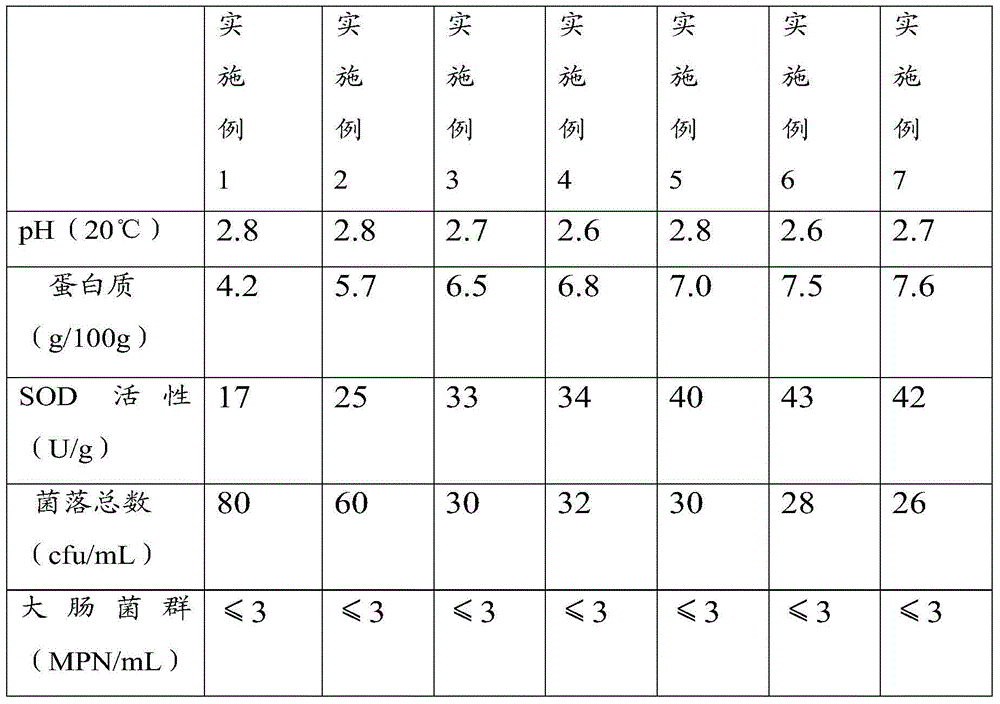

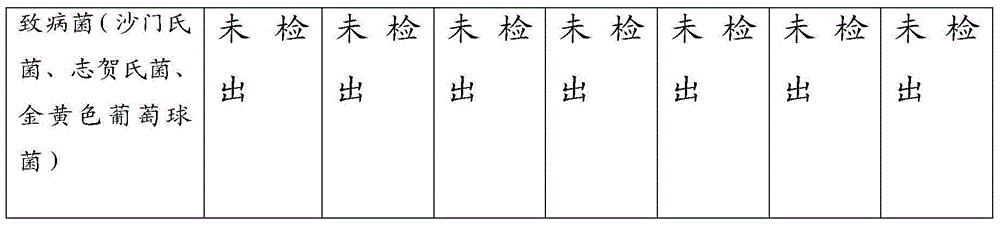

Examples

Embodiment 1

[0031] The plant enzyme solid preparation provided by the present embodiment, raw material comprises:

[0032] 4.5kg of carrots, 0.6kg of beneficial bacteria agent (4 bacteria compound lactic acid bacteria original bacteria powder), 0.9kg of mixed enzyme preparation (composite flavor enzyme) and 1kg of starch are used as auxiliary materials.

[0033] The preparation method comprises the following steps:

[0034] Crush the carrots in a blender to a pulp. The slurry was heated to 50°C, and then the slurry was cooled to 25°C. The slurry was then put into a sealed container and fermented at 25°C for 60 days.

[0035] After the above fermentation was finished, the slurry was left to stand for 24 hours. After 24 hours, the slurry is layered, the upper layer is the fermented enzyme liquid, and the lower layer is the residue after fermentation. Separate the upper enzyme solution. The separated upper enzyme liquid can be used as an enzyme drink through disinfection. Then add bene...

Embodiment 2

[0038] The plant enzyme solid preparation provided by the present embodiment, raw material comprises:

[0039] 5.5kg of kiwi fruit, 1kg of beneficial bacteria agent (4 bacteria compound lactic acid bacteria original bacteria powder), 1.5kg of mixed enzyme preparation (composite flavor enzyme) and 3kg of starch are used as auxiliary materials.

[0040] The preparation method comprises the following steps:

[0041] Peel the kiwi and crush into a paste in a blender. The slurry was heated to 60°C, and then the slurry was cooled to 25°C. The slurry was then put into a sealed container and fermented at 30°C for 60 days.

[0042] After the above fermentation was finished, the slurry was left to stand for 24 hours. After 24 hours, the slurry is layered, the upper layer is the fermented enzyme liquid, and the lower layer is the residue after fermentation. Separate the upper enzyme solution. The separated upper enzyme liquid can be used as an enzyme drink through disinfection. The...

Embodiment 3

[0045] The plant enzyme solid preparation provided by the present embodiment, raw material comprises:

[0046] 5k of soybeans, 0.5kg of Bifidobacterium powder, 0.3kg of Lactobacillus bulgaricus powder, 0.2kg of Streptococcus thermophilus powder, 0.5kg of amylase, 0.5kg of protease and 1kg of lactose are used as auxiliary materials.

[0047] The preparation method comprises the following steps:

[0048] Soybeans are put into water and soaked for 4 hours and then pulverized into a slurry. The slurry was heated to 70°C, and then the slurry was cooled to 25°C. The slurry was then put into a sealed container and fermented at 40°C for 30 days.

[0049] After the above fermentation is finished, the slurry is filtered, and the filtered filter residue is collected. 0.5kg of Bifidobacterium powder, 0.3kg of Lactobacillus bulgaricus powder, 0.2kg of Streptococcus thermophilus powder, 0.5kg of amylase, and 0.5kg of protease in the raw materials were added to the filter residue and mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com