Preparation method of highly efficient amorphous zno/agcl composite visible light photocatalyst

A photocatalyst and amorphous technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., to achieve the effects of easy mass synthesis, enhanced photocatalytic performance, and environmentally friendly raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

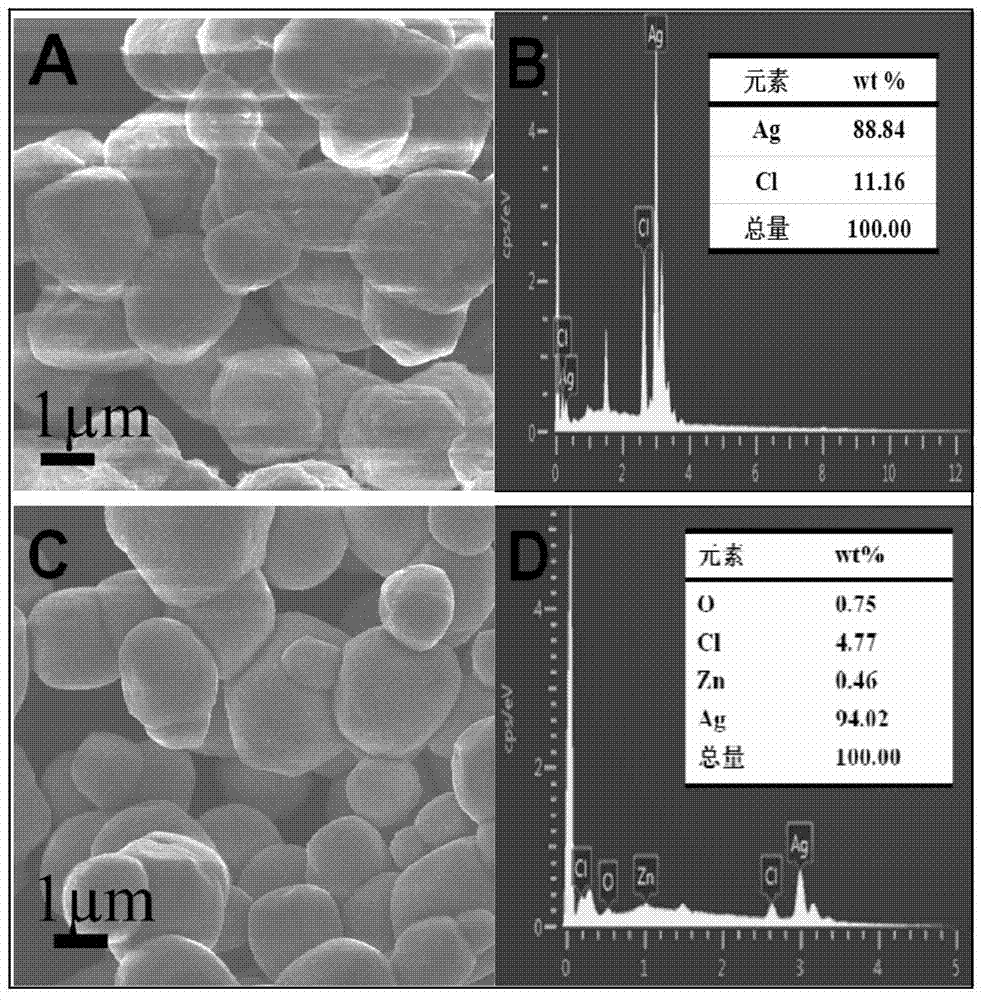

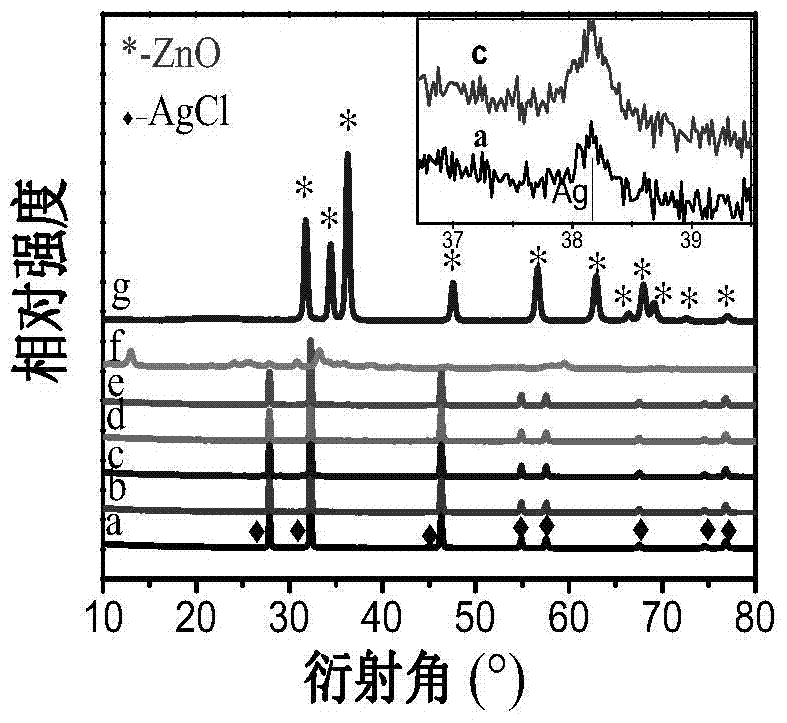

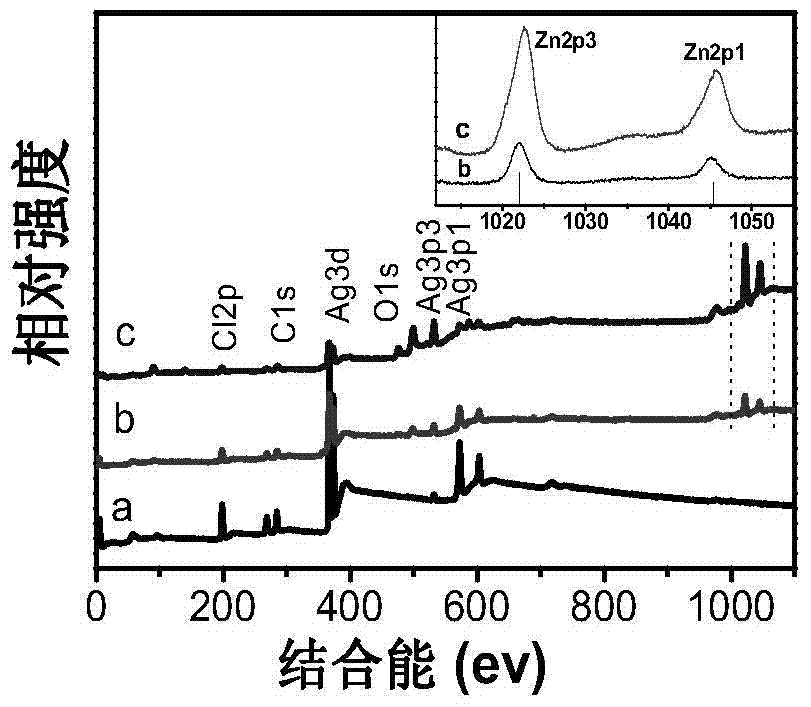

[0034] The preparation process of amorphous ZnO-modified AgCl composite high-efficiency visible light photocatalyst is as follows: 1) Preparation of AgCl powder: under stirring, 34.9 mL of 0.1 mol / L silver nitrate solution was added dropwise to 34.9 mL of 0.1 mol / L chlorine In potassium chloride solution, after reacting for 15 minutes, the resulting product was washed 3 times with deionized water to obtain AgCl powder; 2) Modification of amorphous ZnO on the surface of AgCl powder: take 0.5g AgCl powder and add it to 1ml with a concentration of 7.36× 10 -2 mol / L Zn(NO 3 ) 2 solution and 100ml of urea solution with a concentration of 0.5mol / L, heated to 90°C while stirring, and then stirred for 60min; 3) Light pretreatment: Filter the obtained AgCl powder and wash it with deionized water for 3 times, then add it to 10mL of formazan In base orange solution (20 mg / L), irradiate for 30 min under a xenon lamp that filters out ultraviolet light; 4) Wash the obtained precipitate th...

Embodiment 2

[0042] In order to test the effect of a-ZnO content on the photocatalytic performance of a-ZnO / AgCl composite visible light photocatalyst, in addition to different a-ZnO content, other reaction conditions such as soaking and stirring reaction temperature (90°C) and time (60min), drying temperature (60°C) and drying time (3h) etc. are all the same as in Example 1. The results show that when the content of a-ZnO is 0.1, 0.25, 0.5, 1, 5 and 10wt%, the obtained a-ZnO / AgCl composite visible light photocatalyst has degradation rate constants of methyl orange of 0.0289, 0.0309, 0.0594, 0.0574, 0.0342 and 0.0315min -1 . The main reason is that when the content of a-ZnO is 0.1-0.25wt%, because the content of a-ZnO is too low, only a small amount of a-ZnO is compounded on the surface of AgCl powder, which makes the photocatalytic performance of a-ZnO / AgCl lower ; When the content of a-ZnO is 0.25-1wt%, because a-ZnO can be well compounded on the surface of AgCl powder, it shows signif...

Embodiment 3

[0044] In order to test the effect of soaking and stirring temperature on the photocatalytic performance of a-ZnO / AgCl composite visible light photocatalyst, in addition to different soaking and stirring temperatures, other reaction conditions such as amorphous a-ZnO content (0.5wt%), soaking and stirring time (60min) , drying temperature (60°C) and drying time (3h) etc. are all the same as in Example 1. The results showed that when the immersion and stirring temperatures were 20, 50, 70, 90°C and 95°C, the degradation rate constants of the obtained a-ZnO / AgCl composite visible light photocatalyst for methyl orange were 0.0258, 0.0389, 0.0509, 0.0594 and 0.0436min -1 . The main reason is that when the soaking and stirring temperature is low (20-50°C), urea cannot be fully hydrolyzed, and the amount of amorphous a-ZnO generated by reacting with zinc nitrate is very small, and a-ZnO cannot be well combined with AgCl particles ;When soaking and stirring temperature is 70-90℃, u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com