Preparation method of carbon nanotube

A technology of carbon nanotubes and nanowire arrays, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of high cost, difficult large-scale preparation, high equipment, etc., and achieve low reaction temperature , The preparation method is simple, the effect of easy purification and separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

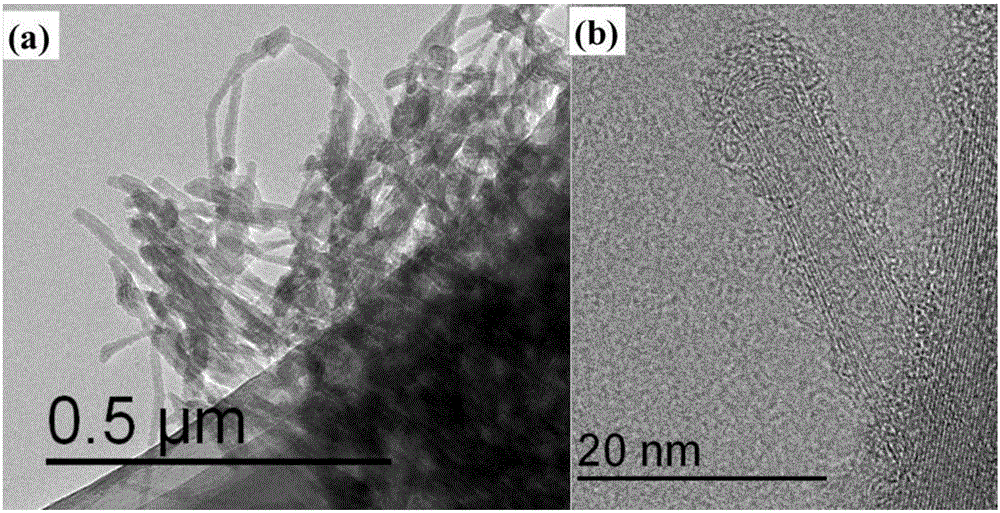

Image

Examples

preparation example Construction

[0028] A method for preparing carbon nanotubes, comprising the steps of:

[0029] A. The silicon wafer is subjected to single-groove electrochemical constant-current corrosion processing to obtain a porous silicon nanowire array;

[0030] B, cutting the porous silicon nanowire array obtained in step A into small pieces, placing it in a reaction vessel, and then adding hexafluoropropylene oxide to the reaction vessel;

[0031] C, heating reaction vessel, then insulation reaction;

[0032] D. After the insulation reaction is completed, reduce the temperature of the reaction vessel, pass the generated gas into the alkaline aqueous solution, then take out the porous silicon nanowire array, and ultrasonically separate it in ethanol or pure water, and finally dry it to obtain carbon nanotubes.

[0033] According to a preferred embodiment of the present invention, the silicon wafer described in step A is a single-sided polished silicon wafer, and the resistivity of the silicon wafer...

Embodiment 1

[0039] The single-sided polished silicon wafer with a resistivity of 3Ω·cm is subjected to single-slot electrochemical constant-current corrosion processing. The electrolyte is 40% hydrofluoric acid, 30% hydrogen peroxide and monohydric alcohol in a volume ratio of 1:2:2. mixed solution;

[0040] The porous silicon nanowire array obtained above was cut into small pieces with a size of 2*2cm, placed in a reaction vessel, and then 5000ml of hexafluoropropylene oxide was added to the reaction vessel;

[0041] Heating the reaction vessel so that the temperature in the reaction vessel is 150°C, and keeping it warm for 60 minutes;

[0042] The temperature of the reaction vessel was lowered to room temperature by natural cooling, the generated gas was passed into an alkaline aqueous solution for absorption, and then the porous silicon nanowire array was taken out, and ethanol was added for ultrasonic separation for 5 minutes, and finally dried to obtain carbon nanotubes.

Embodiment 2

[0044] The single-sided polished silicon wafer with a resistivity of 8Ω cm is subjected to single-slot electrochemical constant-current corrosion processing. The electrolyte is 40% hydrofluoric acid, 30% hydrogen peroxide and monohydric alcohol in a volume ratio of 1:2:2. mixed solution;

[0045] The porous silicon nanowire array obtained above was cut into small pieces with a size of 2*2cm, placed in a reaction vessel, and then 5000ml of hexafluoropropylene oxide was added to the reaction vessel;

[0046] Heat the reaction vessel so that the temperature in the reaction vessel is 180°C, and keep it warm for 30 minutes;

[0047] The temperature of the reaction vessel was lowered to room temperature by natural cooling, the generated gas was passed into an alkaline aqueous solution for absorption, and then the porous silicon nanowire array was taken out, and ethanol was added for ultrasonic separation for 10 minutes, and finally dried to obtain carbon nanotubes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com