Silicone rubber high temperature-resistant conveyor belt

A silicone rubber and high temperature resistant technology, applied in the field of silicone rubber high temperature resistant conveyor belts, can solve problems such as economic losses in transportation engineering, major safety accidents, belt damage, etc., and achieve the goals of improving production efficiency, good mechanical properties, and increasing service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

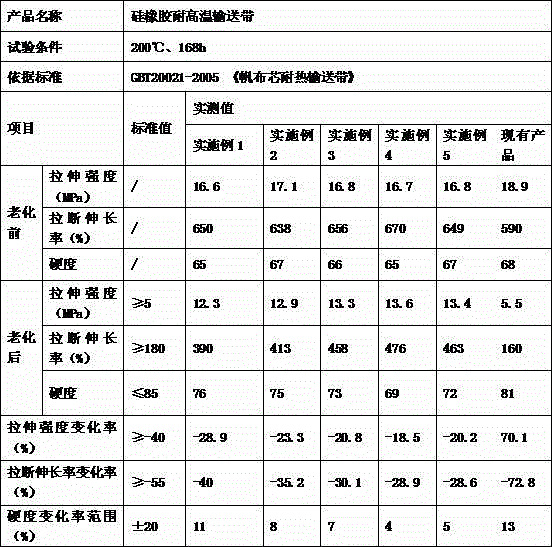

Examples

Embodiment 1

[0016] 1) Turn on the open mill and adjust the temperature. When the temperature rises to about 70°C, put 65 parts of EPDM and 35 parts of silicone rubber into the open mill for mastication, and the masterbatch is well wrapped before feeding;

[0017] 2) Add various compounding agents in sequence: 10 parts of zinc oxide, 5 parts of stearic acid, 2.5 parts of compatibilizer, 6 parts of Si-69 silane coupling agent, 10 parts of coumarone, 3.5 parts of microcrystalline wax, 1.5 parts Anti-aging agent RD, 1.5 parts of anti-aging agent 4020, 1.5 parts of anti-aging agent MB, 50 parts of reinforcing agent N220, 10 parts of white carbon black, 2 parts of accelerator TMTD, 1.5 parts of accelerator CZ, 2 parts of dicumyl peroxide, Fully knead to get the mixed rubber, thin pass 5 times and set aside for use;

[0018] 3) Pass the kneaded film through an open mill to make 2mm×100mm×100mm unvulcanized film, vulcanize it in a vulcanizing machine, the vulcanization condition is 147°C, 30min, ...

Embodiment 2

[0021] 1) Turn on the open mill and adjust the temperature. When the temperature rises to about 70°C, put 70 parts of EPDM and 30 parts of silicone rubber into the open mill for plastication, and the masterbatch is well wrapped before feeding;

[0022] 2) Add various compounding agents in sequence: 10 parts of zinc oxide, 5 parts of stearic acid, 2.5 parts of compatibilizer, 6 parts of Si-69 silane coupling agent, 10 parts of coumarone, 3.5 parts of microcrystalline wax, 1.5 parts Anti-aging agent RD, 1.5 parts of anti-aging agent 4020, 1.5 parts of anti-aging agent MB, 50 parts of reinforcing agent N220, 10 parts of white carbon black, 2 parts of accelerator TMTD, 1.5 parts of accelerator CZ, 2 parts of dicumyl peroxide, Fully knead to get the mixed rubber, thin pass 5 times and set aside for use;

[0023] 3) Pass the kneaded film through an open mill to make a 2mm×100mm×100mm unvulcanized film, and vulcanize it in a vulcanizer under the conditions of 147°C and 30min. Cut th...

Embodiment 3

[0026] 1) Turn on the open mill and adjust the temperature. When the temperature rises to about 70°C, put 70 parts of EPDM and 30 parts of silicone rubber into the open mill for plastication, and the masterbatch is well wrapped before feeding;

[0027] 2) Add various compounding agents in sequence: 15 parts of zinc oxide, 5 parts of stearic acid, 2.5 parts of compatibilizer, 6 parts of Si-69 silane coupling agent, 10 parts of coumarone, 3.5 parts of microcrystalline wax, 1.5 parts Anti-aging agent RD, 1.5 parts of anti-aging agent 4020, 1.5 parts of anti-aging agent MB, 50 parts of reinforcing agent N220, 10 parts of white carbon black, 2 parts of accelerator TMTD, 1.5 parts of accelerator CZ, 2 parts of dicumyl peroxide, Fully knead to get the mixed rubber, thin pass 5 times and set aside for use;

[0028] 3) Pass the kneaded film through an open mill to make a 2mm×100mm×100mm unvulcanized film, and vulcanize it in a vulcanizer under the conditions of 147°C and 30min. Cut th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com