Concentrated liquid degreasing agent for silicon steel continuous annealing production line and preparation method thereof

A production line and degreaser technology, applied in the field of concentrated liquid degreaser and its preparation, can solve the problems of reduced cleaning cost, poor cleaning effect, large amount of foam, etc., and achieve the effects of cost saving, good cleaning effect and strong saponification ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] A preparation method for a concentrated liquid degreasing agent used in a silicon steel continuous annealing production line, the steps of which are:

[0039] Step 1. Add sodium hydroxide to the pure water under the condition of uniform stirring, and the sodium hydroxide dissolves and releases heat;

[0040] Since the sodium hydroxide content reaches 20% to 35%, it will form concentrated lye after dissolution, which can improve its saponification ability and make it easier to remove grease.

[0041] Step 2. When the temperature of the solution reaches 50-80° C., add linear alkenyl dicarboxylic anhydride to the solution, and stir for 10-30 minutes to lower the temperature. Linear alkenyl dicarboxylic acid anhydride is easily soluble in hot alkaline solution, and has good solubility at a temperature of 50-80°C, and can be used as a solubilizer to improve the solubility of other substances; in addition, sufficient stirring can make the reaction proceed quickly, Accelerate...

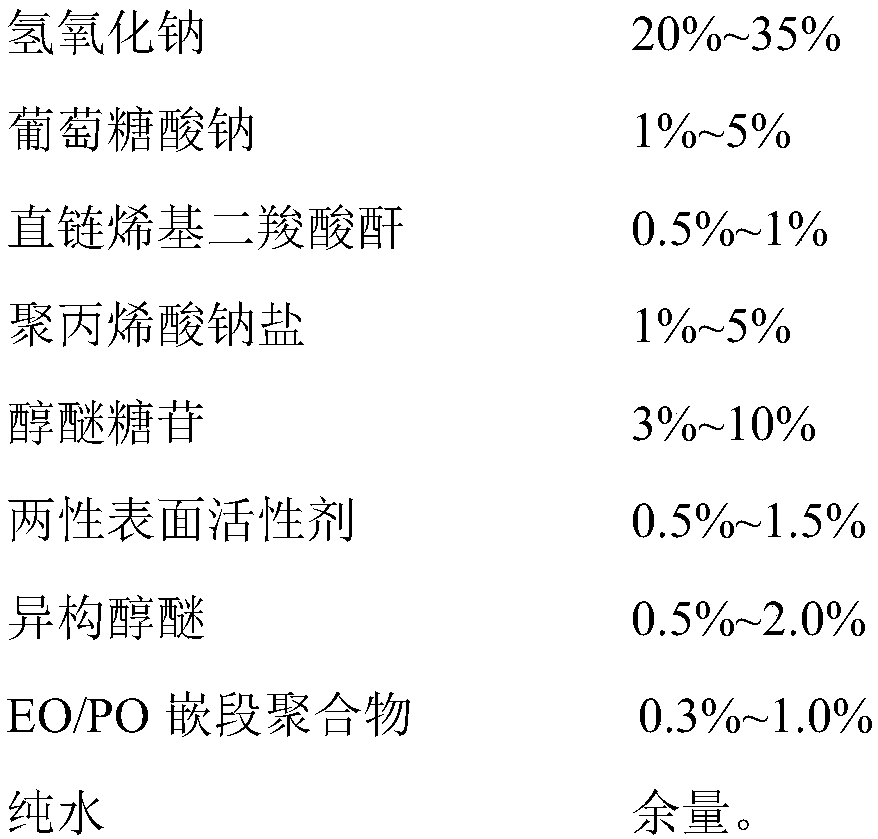

Embodiment 1

[0046] The composition and percentage ratio of the concentrated liquid degreasing agent used in the silicon steel continuous annealing production line in this embodiment are:

[0047]

[0048]

[0049] Prepare the above materials, add pure water into the reactor equipped with thermometer, stirrer and dripping device, start stirring, then slowly add sodium hydroxide until it dissolves completely, and the sodium hydroxide releases a lot of heat when dissolving, making the The water temperature rises; when the water temperature reaches 60°C, add linear alkenyl dicarboxylic anhydride and stir for 10 minutes to dissolve it completely; when the temperature drops to 50°C, add sodium gluconate, polyacrylic acid sodium salt, and alcohol ether in sequence Glycosides and amphoteric surfactants, continue to stir for 60 minutes; finally cool down to 35°C, add isomeric alcohol ethers, EO / PO block polymers in sequence, and stir for 10 minutes to obtain the degreasing agent of the cost e...

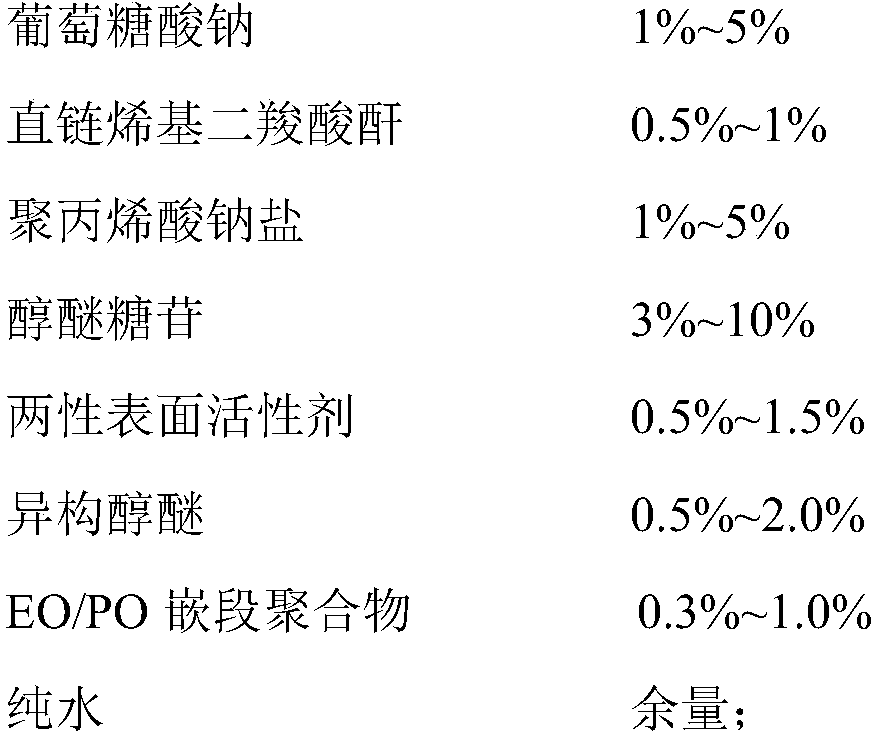

Embodiment 2

[0052] The composition and percentage ratio of the concentrated liquid degreasing agent used in the silicon steel continuous annealing production line in this embodiment are:

[0053]

[0054] Prepare the above materials, add pure water into the reactor equipped with thermometer, stirrer and dripping device, start stirring, add sodium hydroxide in pure water to dissolve completely (exothermic when dissolving), and then add at 80°C Linear alkenyl dicarboxylic acid anhydride, stir for 20min; then cool down to 45°C, add sodium gluconate, polyacrylic acid sodium salt, alcohol ether glycoside, amphoteric surfactant in turn, continue stirring for 30min; finally cool down to 20°C, add iso Construct alcohol ether, EO / PO block polymer, stir 20min namely the degreasing agent of cost embodiment.

[0055] Among the raw materials of the degreasing agent, the linear alkenyl dicarboxylic anhydride is Genapur ASA from Clariant, the sodium polyacrylic acid salt is Sokalan PA30; the alcohol ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com