Copper ion fiber prepared by two-step method and socks

A copper ion, antibacterial fiber technology, applied in the direction of fiber type, fiber treatment, socks, etc., can solve the problems of difficult control and high spinning process requirements, and achieve the effect of enhancing the antibacterial ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

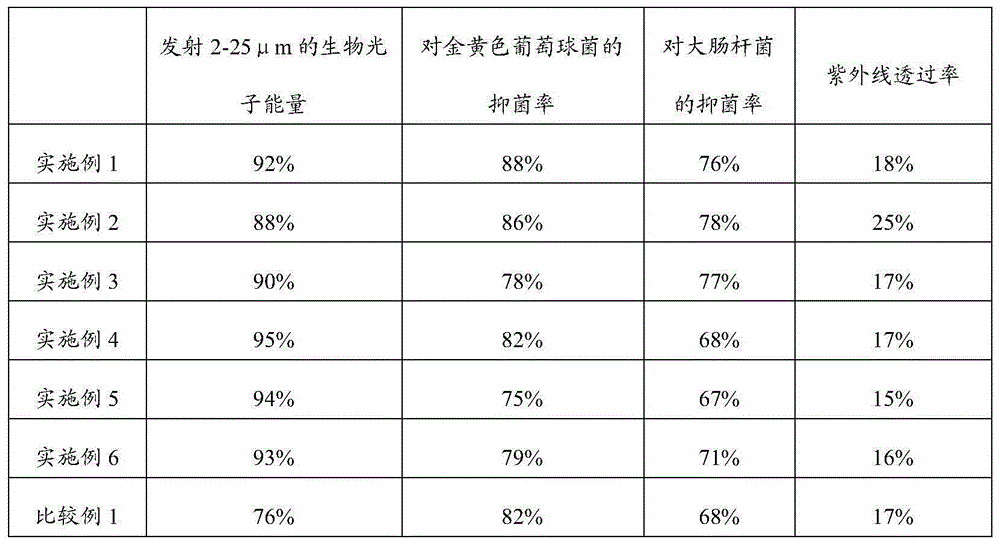

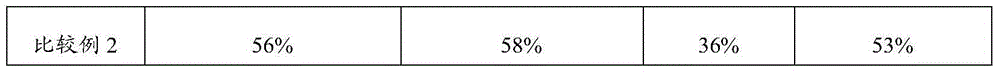

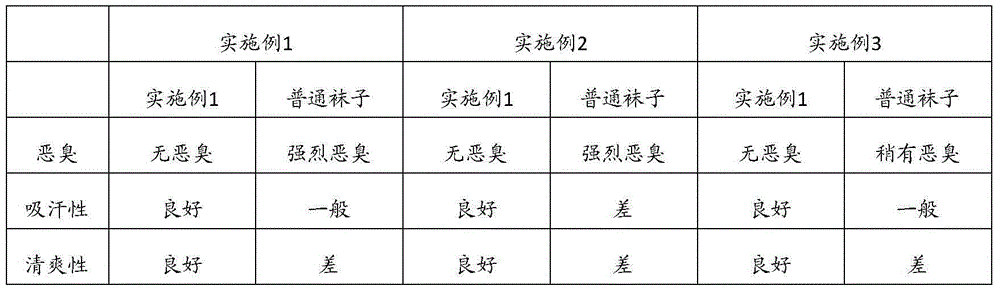

Examples

Embodiment 1

[0021] In the first process, copper sulfate: sodium thiosulfate: sodium citrate is mixed in water according to the ratio of 1:0.1:0.08 by weight to obtain the first treatment solution with copper sulfate as a concentration of 1.1wt%. Immerse in a treatment solution for 0.5 hours at a temperature of 50°C and dry in the sun;

[0022] In the second process, basic blue 9 (Basic Blue 9) and thiabendazole (TBZ) are mixed in water according to the ratio of 1:0.8 by weight to obtain the second treatment solution with a basic blue content of 0.12wt%. The dried acrylic fibers were dipped in the second treatment solution at room temperature, and then heat-treated at 180° C. for 2 hours to obtain copper ion fibers.

[0023] Copper ion fiber: mint fiber: bamboo fiber is blended according to the weight ratio of 30:30:50 and according to the method disclosed in Chinese patent ZL200810000496.7 to make socks.

Embodiment 2

[0025] In the first process, copper sulfate: sodium thiosulfate: sodium citrate is mixed in water according to the ratio of 1:0.15:0.06 by weight to obtain the first treatment solution with copper sulfate as a concentration of 1.2wt%. Immerse in a treatment solution for 0.6 hours at a temperature of 60°C and dry in the sun;

[0026] In the second process, basic blue 9 (Basic Blue 9) and imazalil are mixed in water according to the ratio of 1:1.2 by weight to obtain the second treatment solution with a basic blue content of 0.15wt%, and the dried The acrylic fibers were dipped in the second treatment solution at room temperature, and then heat-treated at 200° C. for 2 hours to obtain copper ion fibers.

[0027] Copper ion fiber: mint fiber: bamboo fiber is blended according to the weight ratio of 30:50:70 and according to the method disclosed in Chinese patent ZL200810000496.7 to make socks.

Embodiment 3

[0029] In the first process, copper sulfate: sodium thiosulfate: sodium citrate is mixed in water according to the ratio of 1:0.1:0.09 by weight to obtain the first treatment solution with copper sulfate as a concentration of 0.8wt%. Immerse in a treatment solution for 1 hour at a temperature of 70°C and dry in the sun;

[0030] In the second process, basic blue 9 (Basic Blue 9) and imazalil are mixed in water at a ratio of 1:0.9 according to the weight ratio to obtain the second treatment solution with a basic blue content of 0.1wt%, and the dried The acrylic fibers were dipped in the second treatment solution at room temperature, and then heat-treated at 220° C. for 1.5 hours to obtain copper ion fibers.

[0031] Copper ion fiber: mint fiber: bamboo fiber is blended according to the weight ratio of 20:45:65 and according to the method disclosed in Chinese patent ZL200810000496.7 to make socks.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com