A Planning Method for Cartesian Space Trajectories of Robots

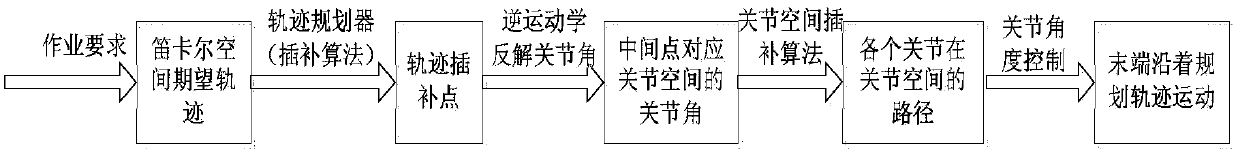

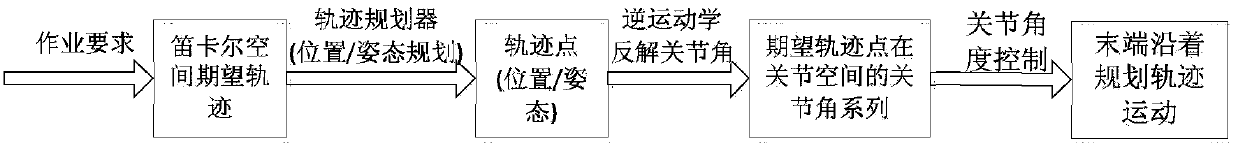

A Cartesian space and robotics technology, applied in the direction of instruments, adaptive control, attitude control, etc., can solve problems such as poor flexibility, heavy computational workload, and singularity of planning paths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0115] Example 1: Connect five-joint Katana and youBot robotic arms in series

[0116] The characteristics of the mechanical arm: the main control joint c of the two is joint 1, the self-optimized joint so is joint 5, and there is no adjustment joint ft, then th=4, mh=3, bh=2, c=1, see Figure 8 and Figure 9 .

[0117] Step 1: Establish the coordinate system of the connecting rod: establish the Z-axis and X-axis of the connecting rod of the robot according to the D-H method, in which the base coordinate system is fixed to the base, and establish each joint coordinate system in turn, and name the rotation angle of each joint axis are θ 1 , θ 2 , θ 3 , θ 4 , θ 5 ; Let the vertical state be the initial shape.

[0118] Step 2: Taking KUKAyouBot as an example, when a 1 =0 means Katana arm, forward kinematics solution process

[0119] Table 1. Mechanical arm D-H connecting rod parameter table

[0120]

[0121]

[0122]

[0123]

[0124]

[0125] Through for...

Embodiment 2

[0217] Example 2: Series five-joint Pioneer-arm arm and series six-joint PUMA560 arm

[0218] The characteristics of the mechanical arm: the main control joint c of the two is joint 1, and the adjustment joint ft is 4. The latter has a self-optimized joint so and is joint 6. If the former does not exist, then th=4, mh=3, bh=2, c= 1, see Figure 10 and Figure 11 . Among them, the serial six-joint type PUMA560 can be regarded as the expansion of the serial five-joint Pioneer type from the less-degree-of-freedom manipulator, achieving five solutions to six.

[0219]Step 1: Establish the coordinate system of the connecting rod: establish the Z-axis and X-axis of the connecting rod of the robot according to the D-H method, in which the base coordinate system is fixed to the base, and establish each joint coordinate system in turn, and name the rotation angle of each joint axis are θ 1 , θ 2 , θ 3 , θ 4 , θ 5 ; Let the vertical state be the initial shape.

[0220] Step 2: ...

Embodiment 3

[0343] Embodiment 3: Humanoid legs of a six-joint humanoid robot in series and its extended redundant legs

[0344] As there is a situation that can move or rotate along or around the base coordinate system x, y, and z directions respectively, the projected position is affected by the movement along the axial direction. At this time, it is necessary to combine the terminal posture to achieve an exact solution for θ c the goal of. The five-axis linkage CNC machine tool can be regarded as a series robot arm, and there are three joints that move along the x, y, and z directions of the base coordinate system.

[0345]Features: For the humanoid leg of a humanoid robot, the main control joint c is joint 1, the self-optimized joint so is the end joint of the redundant leg, and there is no adjustment joint ft, in which the positions of joints 2 and 3 and joints 5 and 6 coincide respectively. Then th=6, mh=4, bh=2, c=1, see Figure 12 and Figure 13 .

[0346] Step 1: Establish the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com