Method of preparing nano-level metal grid transparent conductive film

A technology of transparent conductive film and metal grid, which is applied in the direction of nanotechnology, circuits, electrical components, etc., can solve the problems of passing through, not solving nanoscale graphics, and inability to perform photolithography, etc., and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

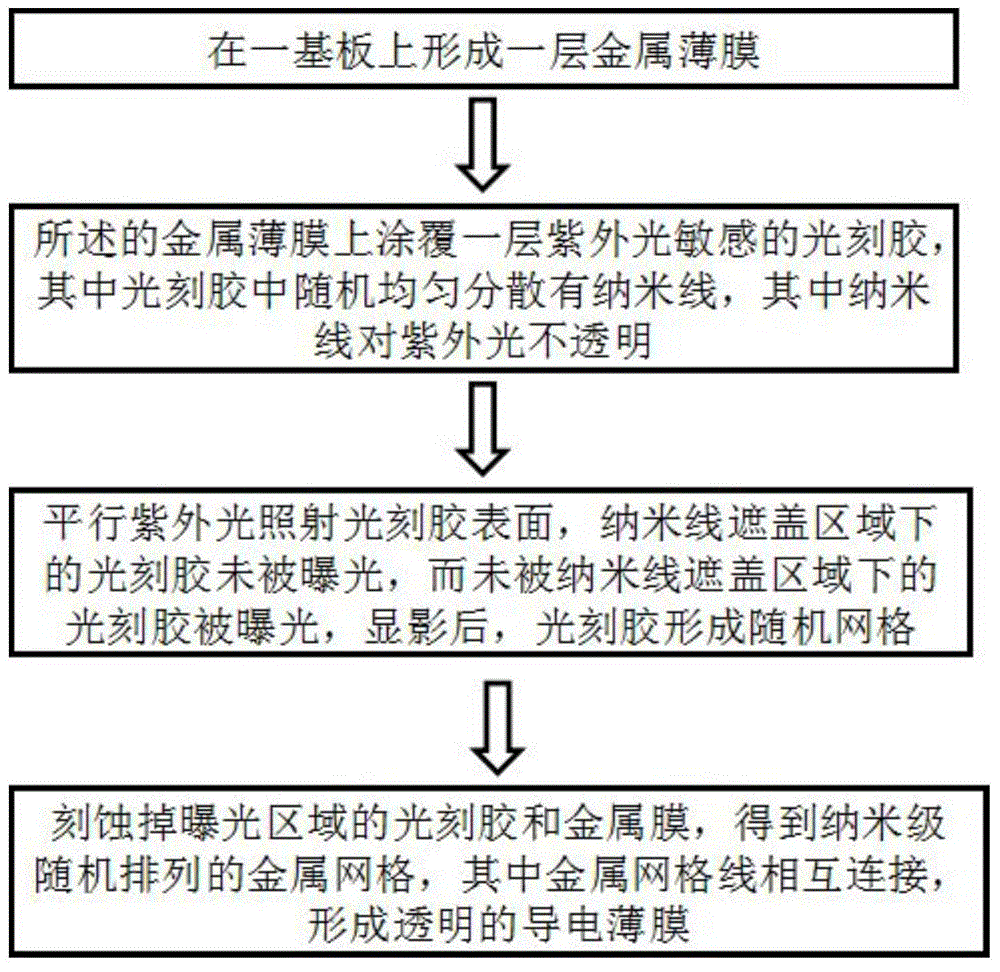

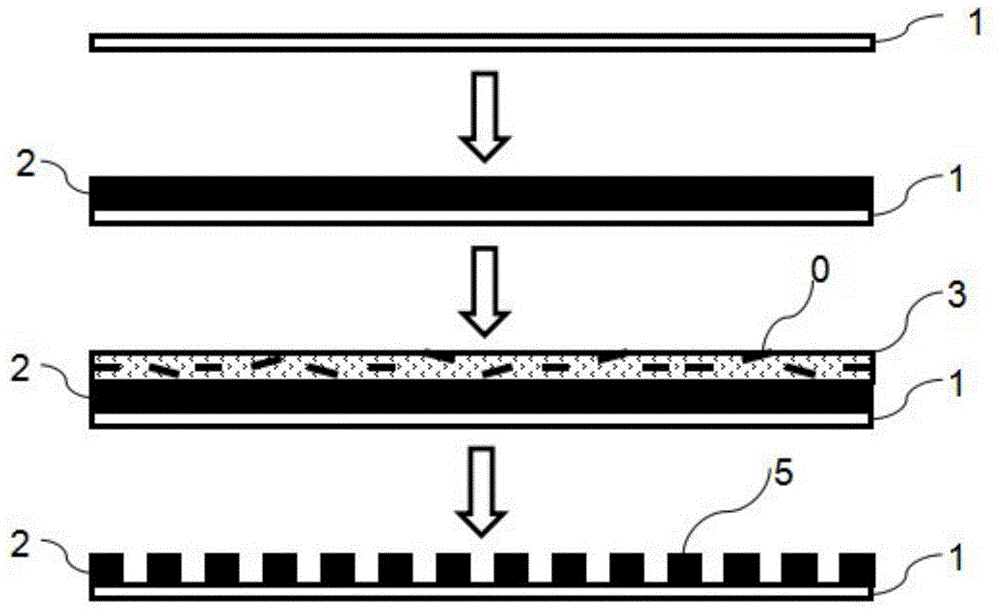

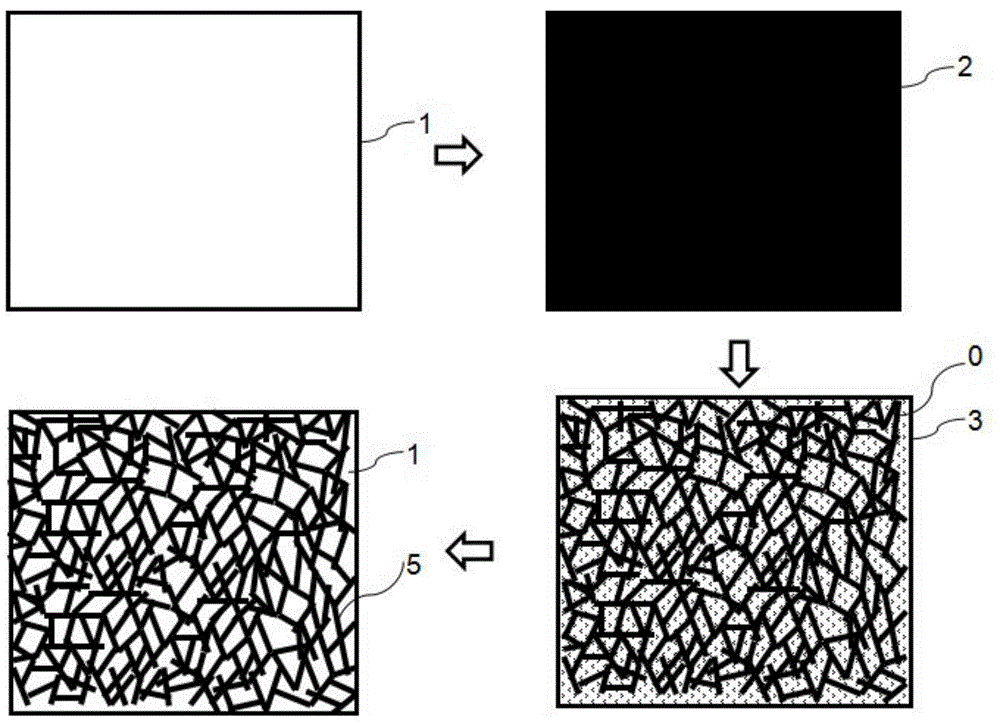

[0035] A method for preparing nanoscale metal grid transparent conductive film, such as figure 1 , figure 2 , image 3 , Figure 4 shown, including the following steps:

[0036] 1) forming a layer of metal thin film 2 on a substrate 1;

[0037] 2) Coating a layer of UV-sensitive photoresist 3 on the metal film 2, wherein the photoresist 3 is randomly and uniformly dispersed with nanowires 0, wherein the nanowires 0 are opaque to ultraviolet light;

[0038] 3) Parallel ultraviolet light irradiates the surface of the photoresist 3, the photoresist 3 under the area covered by the nanowire 0 is not exposed, and the photoresist 3 under the area not covered by the nanowire 0 is exposed, after development, the photoresist 3 form a random grid;

[0039] 4) Etching away the photoresist and the metal film in the exposed area to obtain a metal grid randomly arranged at the nanoscale, wherein the metal grid lines 5 are connected to each other to form a transparent conductive film. ...

Embodiment 2

[0044] A method for preparing nanoscale metal grid transparent conductive film, such as Figure 5 , Figure 6 , Figure 7 , Figure 8 shown, including the following steps:

[0045] 1) forming a layer of metal thin film 2 on a substrate 1;

[0046] 2) Coating a layer of UV-sensitive photoresist 3 on the metal film 2;

[0047]3) Apply a layer of high light-transmitting resin 4 on the photoresist 3, wherein the high light-transmitting resin 4 is randomly and uniformly dispersed with nanowires 0, wherein the nanowires 0 are opaque to ultraviolet light;

[0048] 4) Parallel ultraviolet light is irradiated on the surface of the high light-transmitting resin 4, and the photoresist 3 under the area covered by the nanowire 0 is not exposed, while the photoresist 3 under the area not covered by the nanowire 0 is exposed. Glue 3 forms a random grid;

[0049] 5) Removing the high light-transmitting resin 4, etching away the photoresist 3 and the metal film 2 in the exposed area, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com