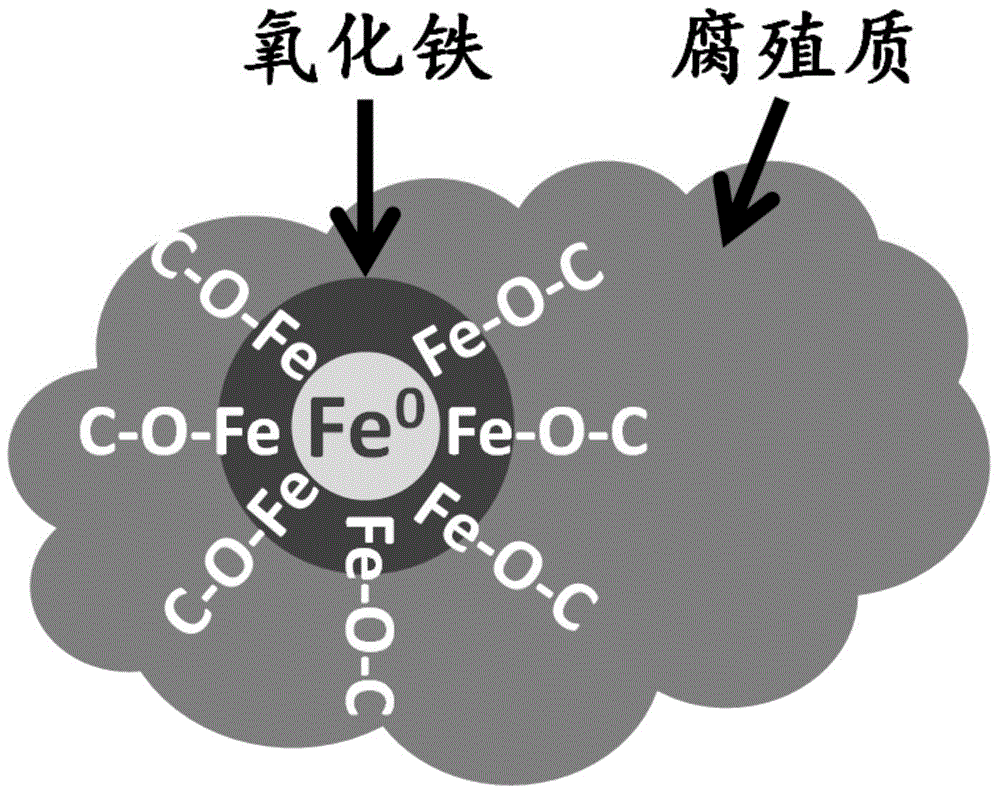

Iron based-humus composite material and application thereof in soil heavy metal pollution control

A composite material and humus technology, which is applied to iron-based-humus composite materials and its application in soil heavy metal pollution control, can solve the problem that arsenic and cadmium composite pollutants are not adsorbed stably at the same time, do not use the high adsorption capacity of humus, and limit adsorption. capacity and other issues, to achieve the effect of accelerating soil microbial metabolism, conducive to healthy growth and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1: the preparation of iron base-humus composite material

[0040] The preparation of the iron-based-humus composite material of the present embodiment comprises the following steps:

[0041] (1) The zero-valent iron powder and the manganese dioxide powder that particle diameter is 50nm are mixed according to the ratio of mass ratio 1:1, then make the iron-manganese suspension of mass percent 10%; Iron-manganese suspension and mass percent 10 % humus aqueous suspension is mixed according to the volume ratio of 1:5, and then the mixed solution is stirred and reacted in a mixer for 4.0h;

[0042] Wherein the humus is the humus extracted from peat soil by the NaOH extraction method launched by the International Humus Association;

[0043] Centrifuge the reacted sample, remove the upper aqueous solution, and retain the solid matter; the solid matter is washed with distilled water for 3 times, dried at 40°C, and pulverized;

[0044] (2) Mix the product obtained i...

Embodiment 2

[0050] Embodiment 2: the preparation of iron base-humus composite material

[0051] The preparation of the iron-based-humus composite material of the present embodiment comprises the following steps:

[0052] (1) The zero-valent iron powder and the manganese dioxide powder that particle diameter is 500nm are mixed according to the ratio of mass ratio 1:0.5, then make the iron-manganese suspension of mass percentage 10%; % humus aqueous suspension is mixed according to the volume ratio of 1:5; then the mixed solution is stirred and reacted in a mixer for 1.5h;

[0053] Wherein the humus is the humus extracted from peat soil by the NaOH extraction method launched by the International Humus Association;

[0054] Centrifuge the reacted sample, remove the upper aqueous solution, and retain the solid matter; the solid matter is washed with distilled water for 3 times, dried at 60°C, and pulverized;

[0055] (2) Mix the product prepared in step (1) with 10wt% polyvinylpyrrolidone s...

Embodiment 3

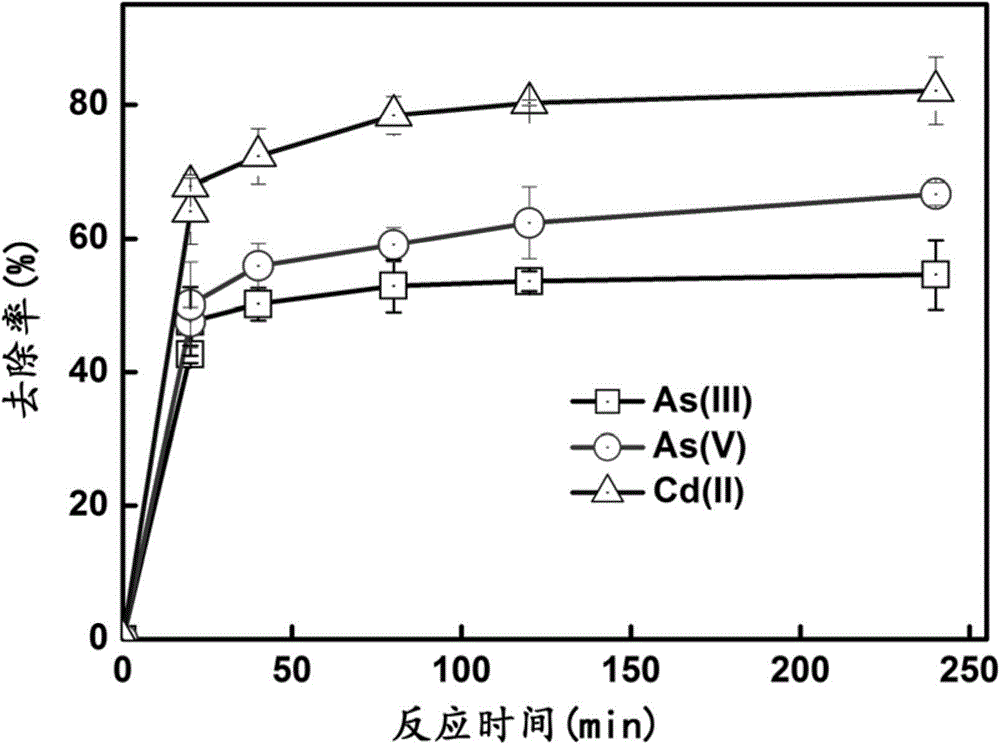

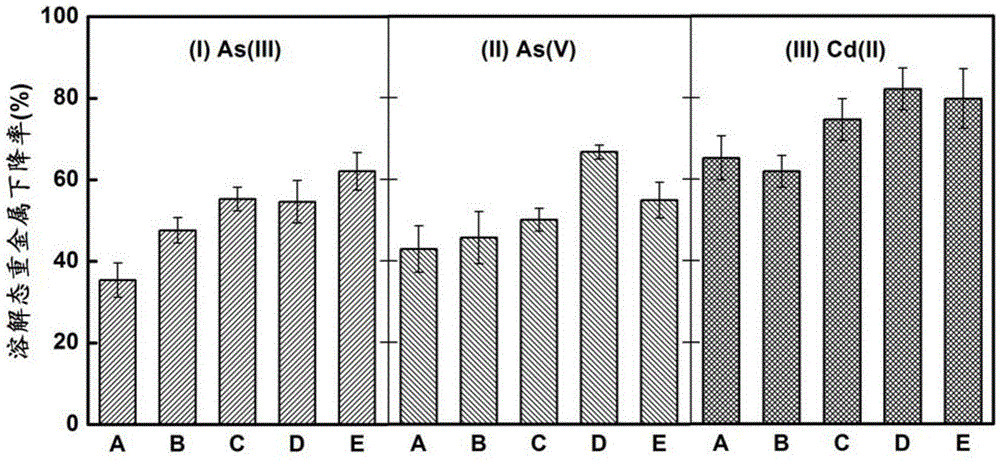

[0060] Example 3: Adsorption experiment of trivalent arsenic, pentavalent arsenic and cadmium ions by iron-based-humic substance composite material

[0061] The iron-based-humus composite material of this embodiment adsorbs and removes arsenic and cadmium. The specific steps are as follows:

[0062] (1) Weigh 0.15g of the iron-based-humus composite material C with an iron loading of 4.7% obtained in Example 1 and add it to a 15mL centrifuge tube, add 2 ), 10mg / L (NaAsO 3 ) and 20mg / L (CdNO 3 ) Mixed solution 15mL, determine the number of reaction centrifuge tubes that need to be arranged according to the number of samples taken and repeated samples;

[0063] (2) Oscillate the mixed reaction solution on a horizontal shaker under dark conditions;

[0064] (3) After the reaction was carried out for 10, 20, 40, 80, 120, and 240 minutes, three reaction samples were taken out and centrifuged; after the supernatant was diluted to an appropriate multiple, the concentration of the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com