Medium-infrared gain sulfide optical fibers and preparation method thereof

A gain fiber and sulfide technology, applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problems of weak luminous intensity, low luminous quantum efficiency, no luminescence, etc., achieve strong luminescence, high luminous quantum efficiency, and reduce relaxation rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] A method for preparing a mid-infrared gain sulfide optical fiber, the method is a rod-tube method, comprising the following steps:

[0025] (1) drawing the optical fiber core glass rod into a thin glass rod near the softening temperature;

[0026] (2) Drilling the optical fiber cladding glass rod along the central axis to obtain a glass sleeve, and polishing the inner wall of the glass sleeve;

[0027] (3) Insert the thin glass rod obtained in step (1) into the glass sleeve obtained in step (2), and draw it into an optical fiber at the softening temperature of the glass, namely 310°C-320°C, to obtain the mid-infrared gain optical fiber of the present invention.

[0028] The optical fiber core glass rod and the cladding glass rod are prepared by the vacuum melting and quenching method commonly used in preparing chalcogenide glass.

Embodiment 1

[0030] Example 1: 0.05% Dy 3+ doped Ga 0.08 Sb 0.32 As 0.05 S 0.55 / Ga 0.08 Sb 0.31 As 0.06 S 0.55 Optical fiber preparation

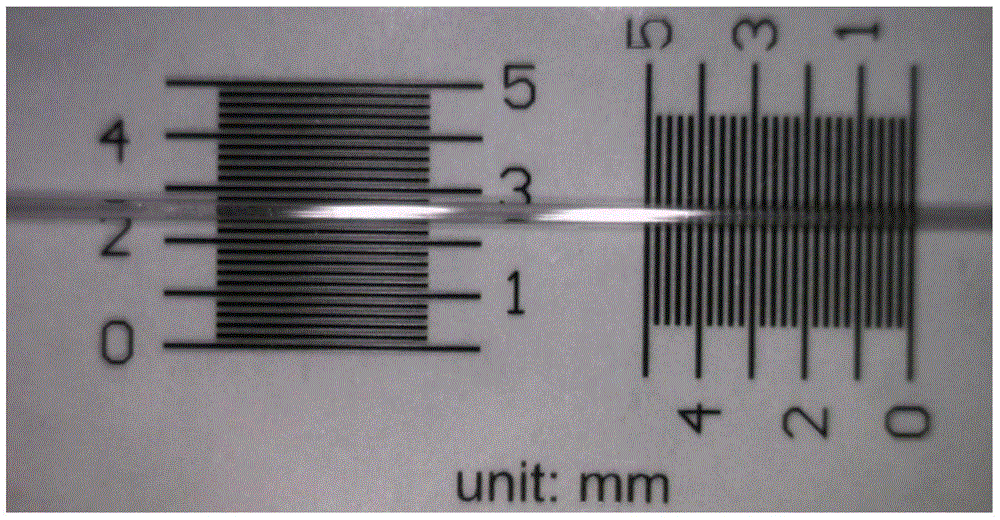

[0031] 0.05% Dy with a diameter of 10 mm was prepared by the vacuum melting-quenching method commonly used in the preparation of chalcogenide glasses 3+ doped Ga 0.08 Sb 0.32 As 0.05 S 0.55 Core glass rod and 10mm diameter Ga 0.08 Sb 0.31 As 0.06 S 0.55 Clad glass rod. Pull the core glass rod at 320°C into a thin glass rod with a diameter of 2.3 mm; drill the fiber cladding glass rod along the central axis to obtain a glass sleeve with an inner diameter of 2.3 mm, and polish the inner wall of the glass sleeve; Insert the obtained thin glass rod with a diameter of 2.3 mm into a glass sleeve, and draw it into an optical fiber with a diameter of 300 μm at 320 ° C to obtain the mid-infrared gain optical fiber of the present invention, as shown in figure 1 shown.

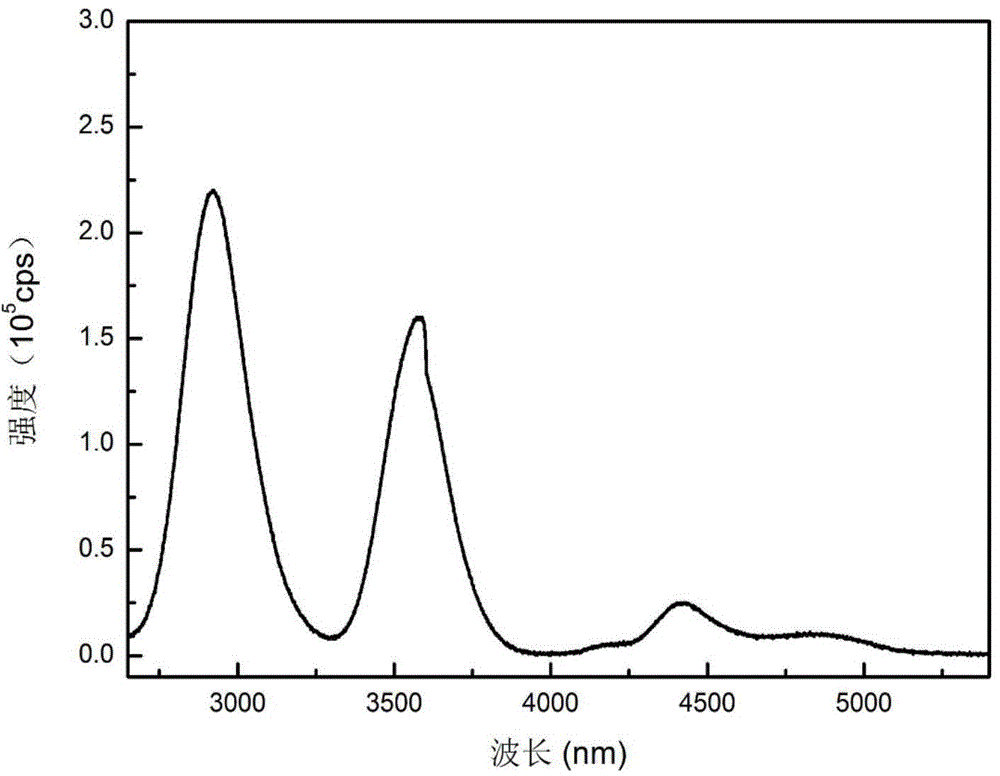

[0032] The test results show that the optical fiber has strong luminescenc...

Embodiment 2

[0033] Example 2: 1% Er 3+ doped Ga 0.06 Sb 0.30 As 0.04 S 0.60 / Ga 0.06 Sb 0.28 As 0.06 S 0.60 Optical fiber preparation

[0034] 1% Er with a diameter of 10 mm was prepared by the vacuum melting-quenching method commonly used in the preparation of chalcogenide glasses 3+ doped Ga 0.06 Sb 0.30 As 0.04 S 0.60 Core glass rod and 10mm diameter Ga 0.06 Sb0.28 As 0.06 S 0.60 Clad glass rod. The core glass rod is drawn at 315°C into a thin glass rod with a diameter of 2.3mm; the fiber cladding glass rod is drilled along the central axis to obtain a glass sleeve with an inner diameter of 2.3mm, and the inner wall of the glass sleeve is polished; The obtained thin glass rod with a diameter of 2.3 mm was inserted into a glass sleeve, and drawn at 315° C. to form an optical fiber with a diameter of 300 μm to obtain the mid-infrared gain optical fiber of the present invention.

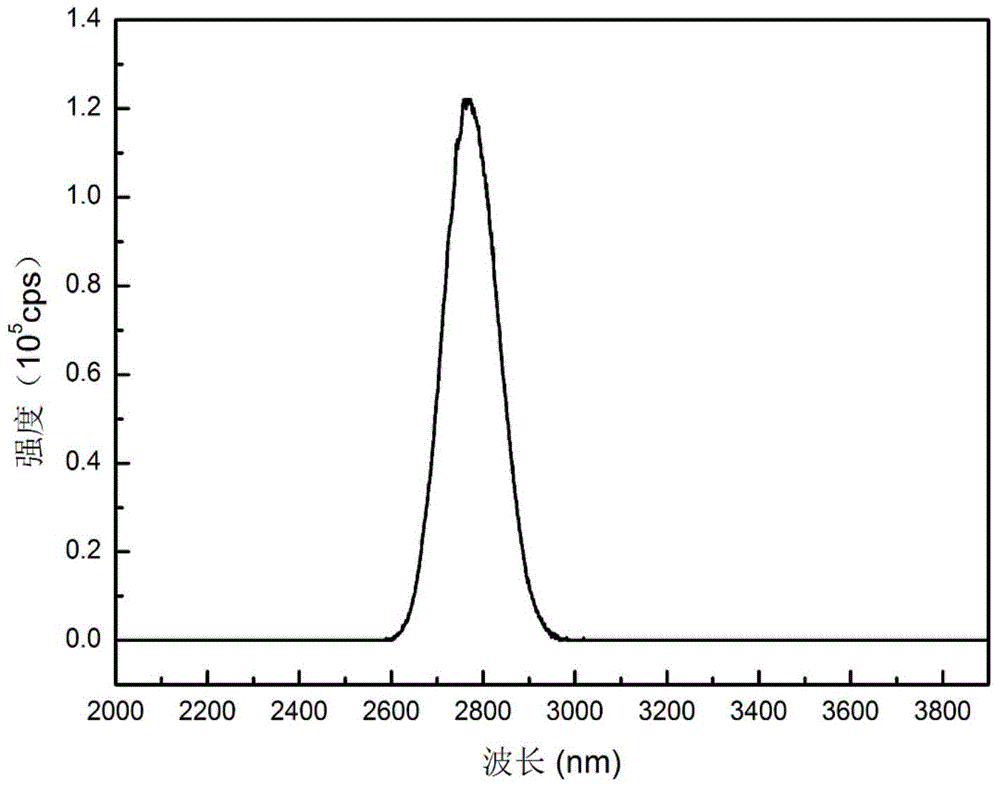

[0035] The test results show that the optical fiber has a strong luminescence at 2.77μm, suc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com