Turbine machinery

A technology of turbo machinery and sealing coating, which is applied in the direction of mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of reducing the leakage resistance effect, reducing the efficiency of the unit, and the wear of seals, so as to improve the mechanical efficiency, Effects of life extension and energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention is described in detail below in conjunction with accompanying drawing:

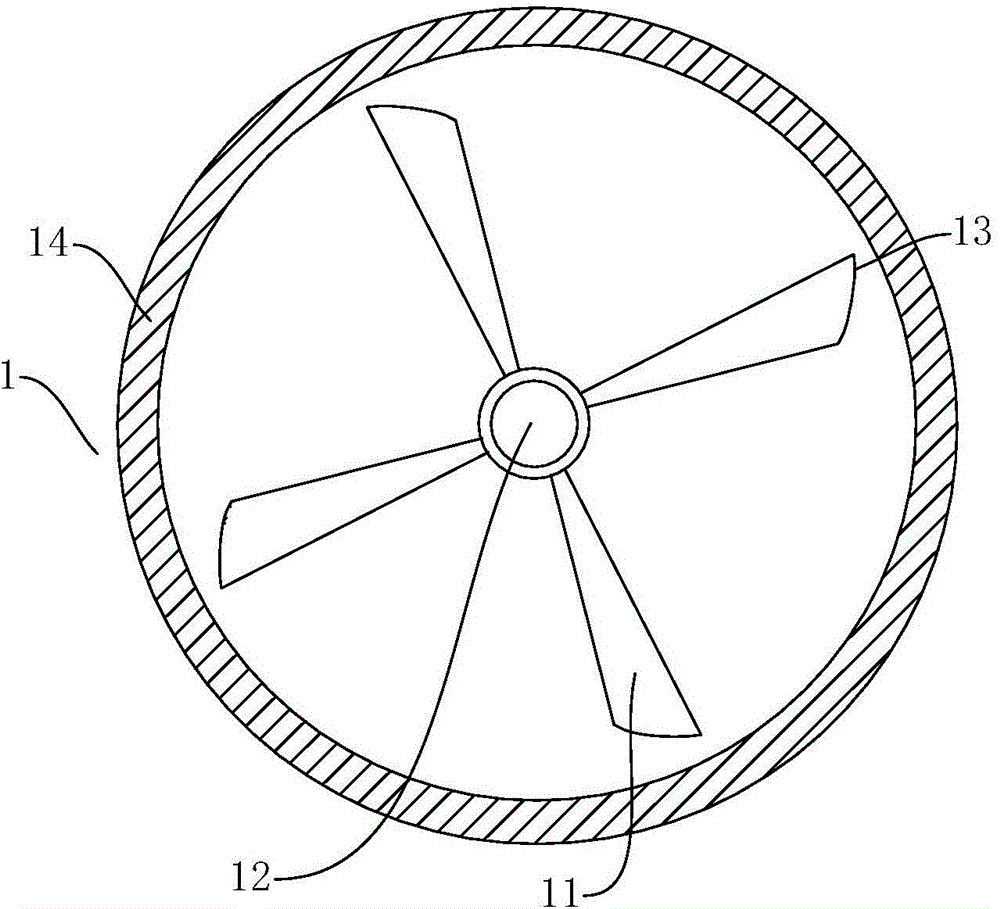

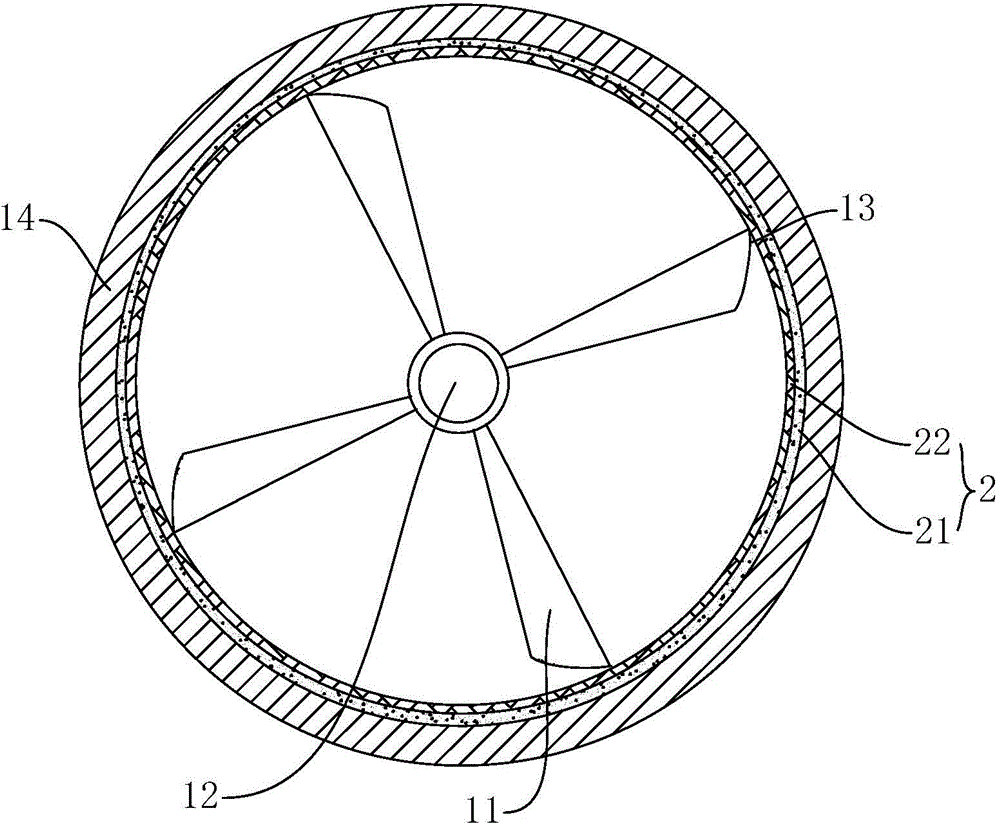

[0041] Such as figure 2 Shown is the internal structure diagram of the turbo compressor. The inner wall of the casing 14 is coated with a sealing coating 2 . The sealing coating 2 includes two layers of sub-coatings, namely an alloy layer 21 coated on the inner wall of the casing 14 and a cermet layer 22 coated on the surface of the alloy layer 21 . In the working state of the turbo compressor, the compressor blades 11 rotate around the rotating shaft 12, and the tip 13 scrapes the cermet layer 22 of the sealing coating 2, so that the gap between the compressor blades 11 and the casing 14 is minimized, reducing the compression. The leakage in the process can be improved, the mechanical efficiency of the turbo compressor can be improved, the energy consumption can be reduced, and the service life can be extended.

[0042] The composition weight percentage content of the all...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com