Sol and method for preparing surface-enhanced Raman substrate

A surface-enhanced Raman and substrate technology, applied in Raman scattering, liquid chemical plating, coating, etc., can solve the problems of high preparation cost, low enhancement factor, complicated and tedious process, etc., and achieves easy preparation and high sensitivity. , the effect of strong performance enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Silver Nanoparticle Synthesis

[0034] Weigh 18 mg silver nitrate (AgNO 3) was dissolved in 100 mL ultrapure water, fully dissolved, and another 2 mL of sodium citrate (Na 3 C 6 h 5 o 7 ) solution (1 wt%) for later use, that is, weigh 0.023 g sodium citrate dihydrate (Na 3 C 6 h 5 o 7 2H 2 O) Dissolve in 2 ml ultrapure water. AgNO 3 The solution was heated to boiling, and Na was gradually added dropwise while stirring. 3 C 6 h 5 o 7 solution to boiling AgNO 3 In the solution, continue to stir and keep the solution boiling for 15 min, then stop heating, and the solution is naturally cooled to room temperature to obtain a gray-green silver sol, which is stored in the dark at 4 °C. The average particle size of the synthesized silver nanoparticles is about 60 nm, and the maximum absorption wavelength is 425 nm when irradiated with ultraviolet-visible light.

[0035] Self-Assembly of Silver Nanoparticles on the Surface of Si Sheet

[0036] 0.5 ml of ascorbic...

Embodiment 2

[0046] Silver Nanoparticle Synthesis

[0047] Weigh 18 mg silver nitrate (AgNO 3 ) was dissolved in 100 mL ultrapure water, fully dissolved, and another 3 mL of sodium citrate (Na 3 C 6 h 5 o 7 ) solution (1 wt%) for later use. AgNO 3 The solution was heated to boiling, and Na was gradually added dropwise while stirring. 3 C 6 h 5 o 7 solution to boiling AgNO 3 In the solution, continue to stir and keep the solution in a boiling state for 60 min, then stop heating, and the solution is naturally cooled to room temperature to obtain a gray-green silver sol, which is stored in the dark at 4 °C. The average size of the synthesized silver nanoparticles is about 59 nm.

[0048] Self-Assembly of Silver Nanoparticles on the Surface of Si Sheet

[0049] 0.04 ml of ascorbic acid (AA) was added to 20 ml of freshly prepared silver sol under vigorous stirring to activate it. A 1 cm×1 cm silicon wafer was washed with ultrapure water, acetone, ethanol, and ultrapure water in seq...

Embodiment 3

[0053] Silver Nanoparticle Synthesis

[0054] Silver nanoparticles were synthesized according to the method of Example 1.

[0055] Self-Assembly of Silver Nanoparticles on the Surface of Si Sheet

[0056] Activate by adding 2 ml of 0.1 M ascorbic acid (AA) to 20 ml of freshly prepared silver sol under vigorous stirring. A 1 cm×1 cm silicon wafer was washed with ultrapure water, acetone, ethanol, and ultrapure water in sequence, and N 2 blow dry. Then immersed in the activated silver sol, assembled for 1 h.

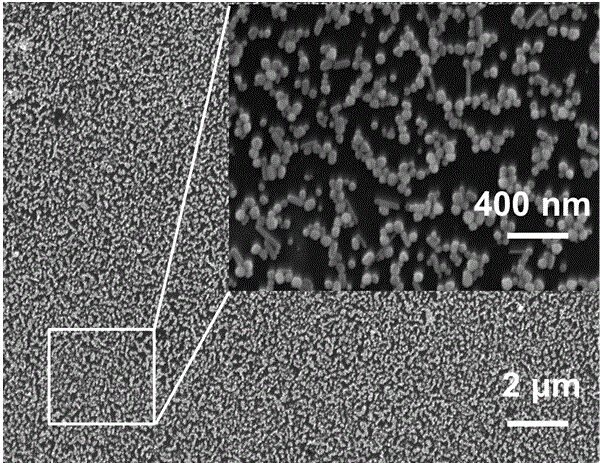

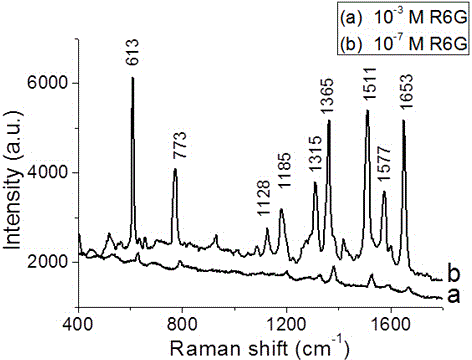

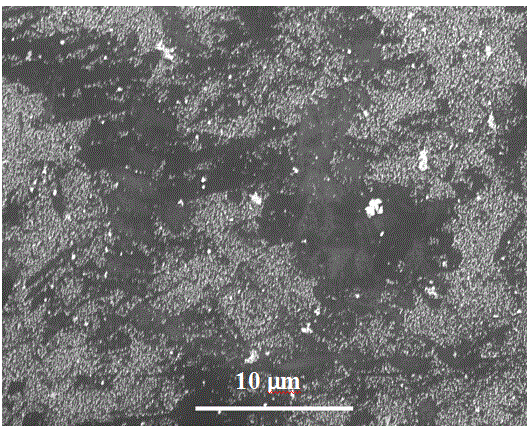

[0057] Morphology and property analysis of surface-enhanced Raman substrates

[0058] Figure 4 It is the SEM image of the silver nanoparticles assembled on the Si surface after adding the activator AA. It can be seen that the AgNPs are assembled into a single layer, but due to the large amount of AA added, AgNPs aggregate in some areas. When using R6G to detect its Raman performance, it is measured that 10 -7 M R6G I SERS =9.83×10 4 , the Raman enhancement eff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com