Fluid electric energy feedback type semi-active control shock absorber system

A semi-active control and shock absorber technology, which is applied in the direction of liquid shock absorbers, shock absorbers, fluid pressure actuation system components, etc., can solve the problem that the performance of shock absorbers is difficult to meet the driving requirements of vehicles, and it is not suitable for long-term practical applications. Use, reciprocating compression of the spring-loaded mass, etc., to achieve the effect of excellent external characteristics, simple structure, and small changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

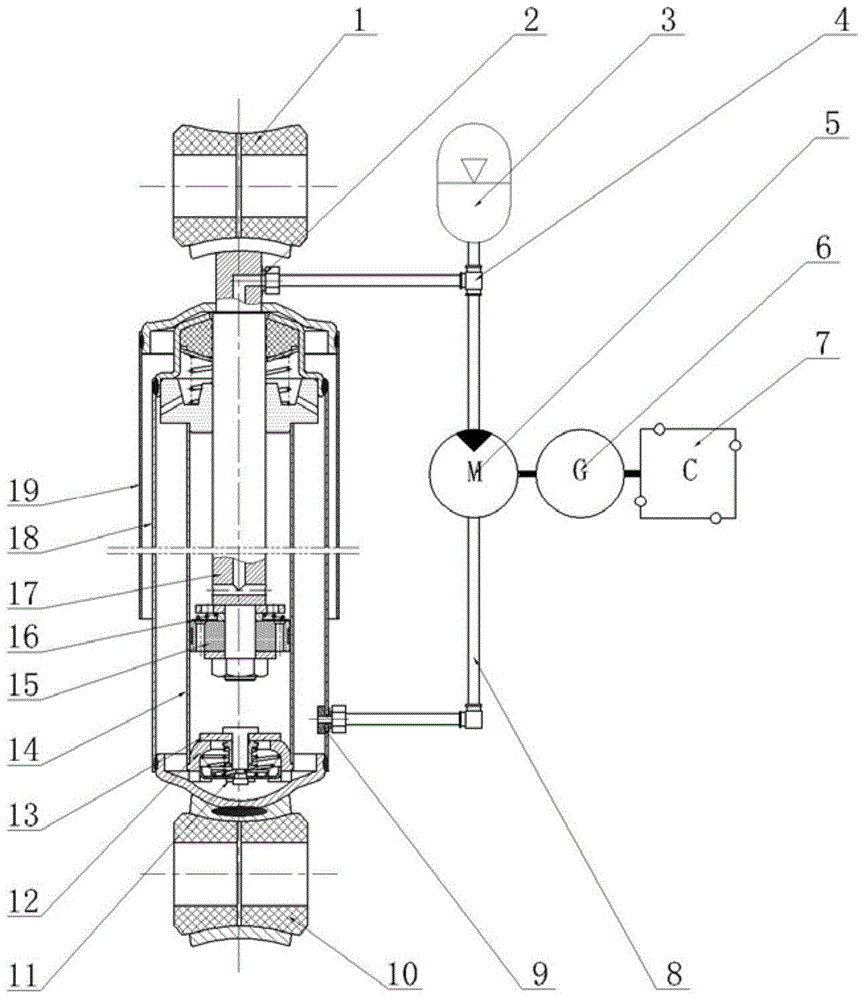

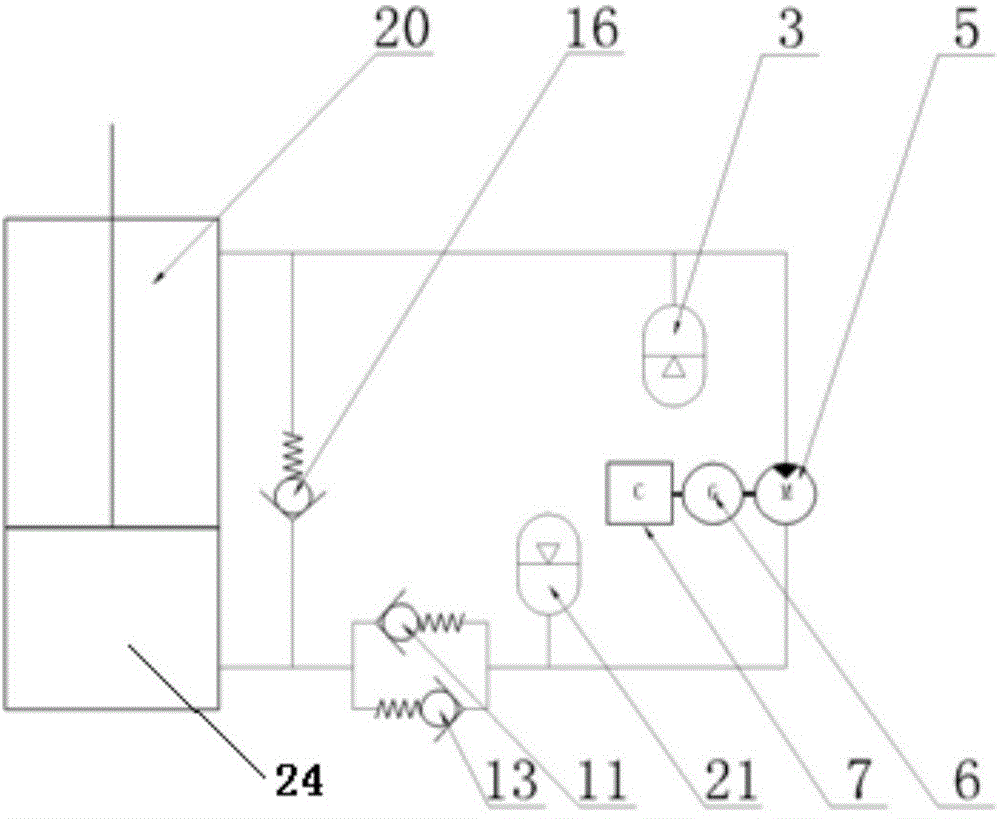

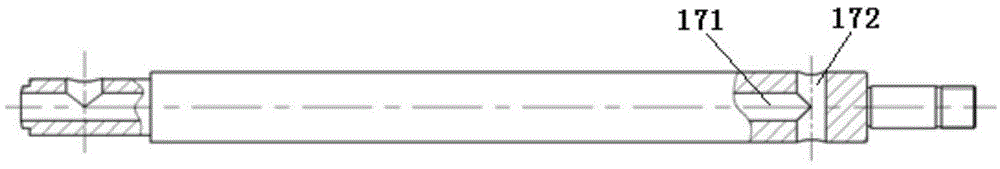

[0025] The present invention will be described in detail below in conjunction with the drawings: as attached figure 1 , 2 As shown, the present invention mainly includes a double-barrel hydraulic damping module composed of a hydraulic working cylinder 14, a storage cylinder 18, a piston 15, a hollow piston rod 17, a compression valve 11, and a compensation valve 12, and a hollow piston rod adapter 2, The accumulator 3, the oil storage cylinder adapter 9, the hydraulic energy feed pipe 8, the hydraulic motor 5, the generator 6, and the load control circuit 7 constitute the hydraulic and electric energy feed control module. A round hole is drilled through which the oil storage cylinder adapter 9 is welded; the top end of the hollow piston rod 17 in the hydraulic working cylinder 14 radially leads out an oil outlet, and the hollow piston is welded at the oil outlet Rod adapter 2; the front end of the hydraulic motor 5 is connected to the hollow piston rod adapter 2 of the hollow pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com