Collagen membrane and preparation method thereof

A collagen film and collagen technology, applied in the field of collagen film and its preparation, can solve the problem of single efficacy of collagen film, achieve good therapeutic effect, prolong storage time, and accelerate regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

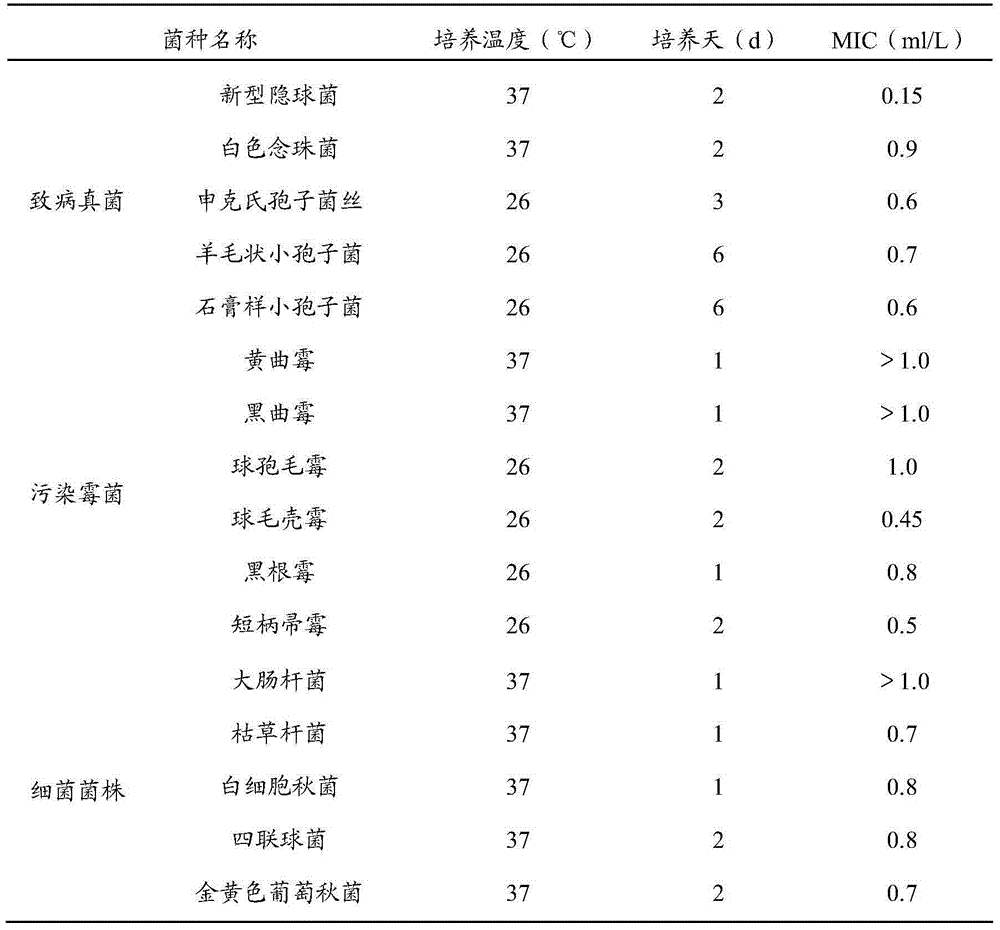

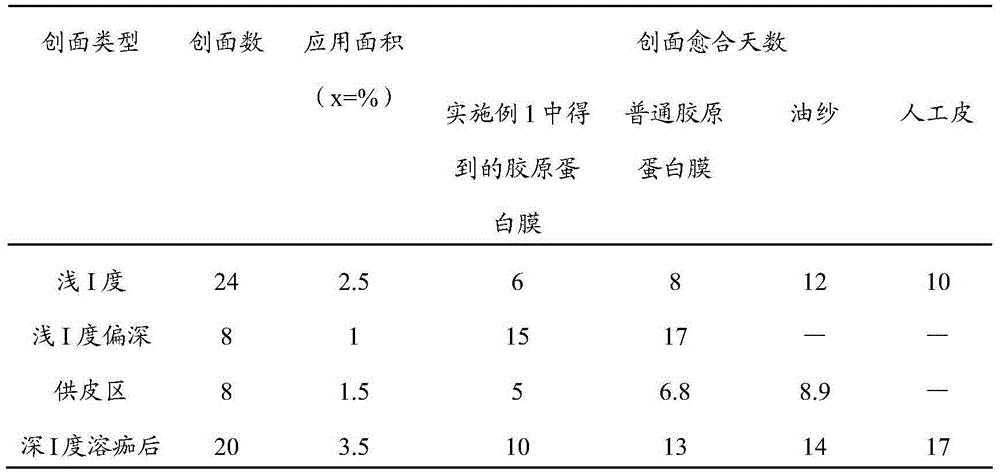

Examples

preparation example Construction

[0028] The present invention also provides a preparation method of the above-mentioned collagen film, comprising: mixing collagen, patchouli oil and glacial acetic acid aqueous solution, then adjusting the pH value to 5-6, gelling, cross-linking and drying at low temperature, Obtain a collagen film.

[0029] Wherein said collagen, patchouli oil and glacial acetic acid are all the same as above, and will not be repeated here.

[0030] According to the present invention, preferably first collagen is mixed with glacial acetic acid aqueous solution; The concentration of described glacial acetic acid aqueous solution is preferably 0.05~0.1mol / L; The pH value of described glacial acetic acid aqueous solution is preferably 3.2~4.5; The temperature of described mixing Preferably it is 4°C to 10°C, more preferably 4°C to 8°C. Mixing at this temperature can well protect the collagen triple helix structure. After mixing, it is preferable to stir at a uniform speed until completely diss...

Embodiment 1

[0043] 1.1 Add collagen to glacial acetic acid solution (pH3.2) with a concentration of 0.05mol / L and mix, control the temperature at 4°C, stir at a constant speed until the solution is complete, and obtain a collagen-acetic acid solution with a collagen mass concentration of 2.5% .

[0044] 1.2 Based on the collagen-acetic acid solution, add 0.05ml / L patchouli oil, 0.15ml / L litsea cubeba oil, 5ml / L turmeric volatile oil, and 0.2ml / L long Torreya volatile oil, 0.2ml / L volatile oil of bay leaf and 6ml / L garlic volatile oil to obtain Chinese medicine collagen solution.

[0045] 1.3 Add phenol red solution to the traditional Chinese medicine collagen solution obtained in 1.2, and adjust the pH value of the solution to 5.0.

[0046] 1.4 Gel: Put the solution obtained in 1.3 into a gel mold and gel at 4°C for 2 hours to obtain a collagen film.

[0047] 1.5 Crosslinking: put the collagen membrane obtained in 1.4 into 0.01mol / L EDC crosslinking agent for crosslinking for 10h, take ...

Embodiment 2

[0051] 2.1 Add collagen to glacial acetic acid solution (pH4.0) with a concentration of 0.5mol / L and mix, control the temperature at 4°C, stir at a constant speed until the solution is complete, and obtain a collagen-acetic acid solution with a collagen mass concentration of 3%. .

[0052] 2.2 Based on the collagen-acetic acid solution, add 0.5ml / L patchouli oil, 0.25ml / L litsea cubeba oil, 6ml / L turmeric volatile oil, and 0.25ml / L long Torreya volatile oil, 0.3ml / L volatile oil of bay leaf and 9ml / L garlic volatile oil to obtain Chinese medicine collagen solution.

[0053] 2.3 Add phenol red solution to the traditional Chinese medicine collagen solution obtained in 2.2, and adjust the pH value of the solution to 5.8.

[0054] 2.4 Gel: Put the solution obtained in 2.3 into a gel mold and gel at 4°C for 3 hours to obtain a collagen film.

[0055] 2.5 Crosslinking: put the collagen membrane obtained in 2.4 into 0.03mol / L EDC crosslinking agent for crosslinking for 10h, take ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com