Preparation method for high anti-tracking halogen-free flame-retardant glass-cloth laminate

A tracking-resistant and tracking-resistant technology is applied in lamination, lamination devices, chemical instruments and methods, etc. It can solve problems such as fire, short-circuit fire, and easy sparks, and achieves increased resin stability and increased polarity. Sexual group ratio, the effect of satisfying alcohol solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

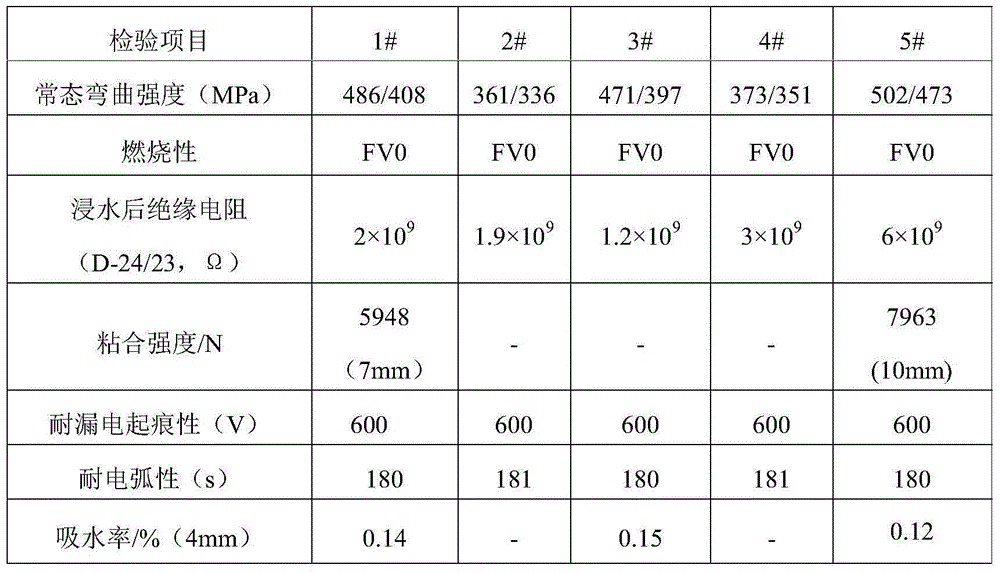

Examples

Embodiment 1

[0022] (1) Synthesis of melamine formaldehyde resin:

[0023] Put 100g of formaldehyde solution (37%), 73.5g of paraformaldehyde and 90g of methanol into the reactor, slowly raise the temperature to 70-80°C and keep it warm for 30min; , heat up to 70-80°C and react for 50 minutes, cool down to stop the reaction, and set aside;

[0024] (2) Synthesis of alcohol-soluble bisphenol A type epoxy resin

[0025] Add 300g of F51, 30g of propylene glycol monomethyl ether and 20g of methanol to the reactor in turn, heat to 70-80°C, stir and react for 30min, add 80.4g of diethanolamine and 94g of methanol, continue to react at 70-80°C for 120min, add 50g of methanol cooling to terminate the reaction, standby;

[0026] (3) Preparation of halogen-free flame retardant resin system

[0027] The above self-made melamine formaldehyde resin and alcohol-soluble bisphenol A epoxy resin are mixed according to the dry resin weight ratio of 2:1, and the molding time is tested by sampling (70-300s...

Embodiment 2

[0030] (1) Synthesis of melamine formaldehyde resin:

[0031] 100g of formaldehyde solution (37%) and about 0.25g of guanidine carbonate were put into the reactor, the pH was controlled at 9-10, 100g of melamine was put into the reactor, the temperature was slowly raised to 70-80°C and then kept for 60min; Adjust the pH to 5-6 with about g of oxalic acid, raise the temperature to 50-60°C for 30 minutes, adjust the pH to 9-10 with about 0.82g of guanidine carbonate, add 54.6g of melamine and 82.5g of paraformaldehyde respectively, and raise the temperature to 70-60°C. React at 80°C for 60 minutes, cool down and add 206g of methanol to stop the reaction, and set aside;

[0032] (2) Synthesis of alcohol-soluble bisphenol A type epoxy resin

[0033] Add 300g of E-35, 10g of propylene glycol monomethyl ether and 35g of methanol to the reactor successively, heat to 70-80°C, stir and react for 30min, then add 33.1g of diethanolamine and 80g of methanol, and continue to react at 70-8...

Embodiment 3

[0038] (1) Synthesis of melamine formaldehyde resin:

[0039] 202g of formaldehyde solution (37%), 35.2g of paraformaldehyde, 119g of methanol and 150g of melamine were put into the reactor respectively, and the temperature was slowly raised to 70-80°C and then kept for 15 minutes. React at ~80°C for 60 minutes, cool down to stop the reaction, and set aside;

[0040] (2) Synthesis of alcohol-soluble bisphenol A type epoxy resin

[0041] Add 300g E-51, 10 propylene glycol monomethyl ether and 40g methanol to the reactor successively, heat to 70-80°C, stir for 30min, then add 128.7g of diethanolamine and 70g of methanol, and continue to react at 70-80°C for 120min , add 74g methanol to cool down to terminate the reaction, set aside;

[0042] (3) Preparation of halogen-free flame retardant resin system

[0043] The above self-made melamine formaldehyde resin and alcohol-soluble bisphenol A epoxy resin are mixed according to the dry resin weight ratio of 3:1, and the molding ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com