Acrylate modified hydroxyl-terminated butadiene resin with low infrared emissivity, and preparation method thereof

A hydroxyl-terminated polybutadiene, low infrared emission technology, applied in the field of resin, can solve the problems of high reflectivity, insufficient paint film resistance, poor weather resistance, etc., and achieves good infrared transparency, enhanced salt spray resistance, Excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

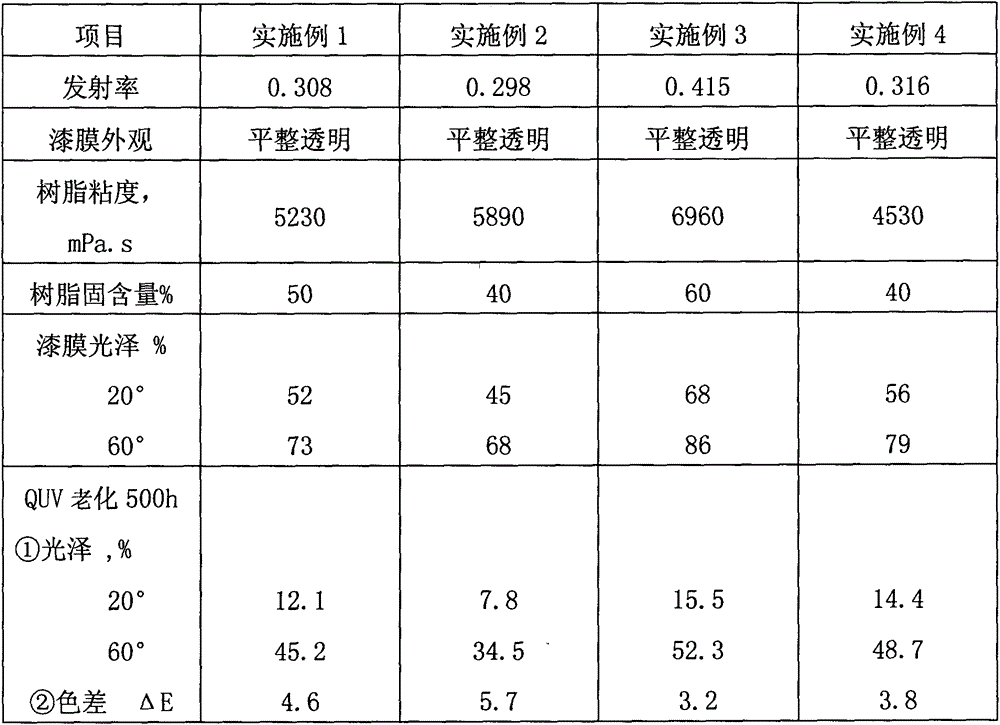

Examples

Embodiment 1

[0026] (Example 1, the acrylate-modified hydroxyl-terminated polybutadiene resin of low infrared emissivity)

[0027] The acrylate-modified hydroxyl-terminated polybutadiene resin with low infrared emissivity in this embodiment is obtained by radical copolymerization of hydroxyl-terminated polybutadiene and acrylate monomers and / or methacrylate monomers. The amount of each raw material in the radical copolymerization reaction is as follows: 5wt%-15wt% of hydroxyl-terminated polybutadiene, 25wt%-55wt% of acrylate monomer or methacrylate monomer, 35wt%-65wt% of solvent, and 0.5wt% of initiator % to 2 wt%, the sum of the amount of each raw material is 100 wt%, and the solid content of the obtained acrylate-modified hydroxyl-terminated polybutadiene resin with low infrared emissivity is 40-60 wt%.

[0028] The hydroxyl-terminated polybutadiene is a homopolymer of butadiene with a number average molecular weight of 2000-3000. There are more than two hydroxyl groups on average at b...

Embodiment 2

[0032](The preparation method of the acrylate-modified hydroxyl-terminated polybutadiene resin of embodiment 2, low infrared emissivity)

[0033] The preparation method of the acrylate-modified hydroxyl-terminated polybutadiene resin of the low infrared emissivity of the present embodiment is as follows:

[0034] In a 500mL four-necked reaction flask equipped with a stirrer, a thermometer, a dropping funnel and a condenser, add solvent xylene 200g (accounting for 40wt% of the total amount of reaction feed), 50g of hydroxyl-terminated polybutadiene (accounting for reaction feed 10wt% of the total amount), under the protection of a nitrogen atmosphere, start the stirrer, and heat the material in the reaction bottle to 80°C.

[0035] Open the dropping funnel and start to add 200 g of the mixed solution of acrylate monomer and / or methacrylate monomer and initiator in the dropping funnel at a constant speed. In this embodiment, the mixed solution in the dropping funnel includes met...

Embodiment 3

[0037] (The preparation method of the acrylate-modified hydroxyl-terminated polybutadiene resin of embodiment 3, low infrared emissivity)

[0038] The preparation method of the acrylate-modified hydroxyl-terminated polybutadiene resin of the low infrared emissivity of the present embodiment is as follows:

[0039] In a 500mL four-necked reaction flask equipped with a stirrer, a thermometer, a dropping funnel and a condenser, add solvent toluene 250g (accounting for 50wt% of the total amount of the reaction feed), 50g of hydroxyl-terminated polybutadiene (accounting for the total amount of the reaction feed). 10wt% of the amount), under the protection of a nitrogen atmosphere, start the stirrer, and heat the material in the reaction bottle to 100 ° C.

[0040] Open the dropping funnel and start to add 150 g of the mixed solution of acrylate monomer and / or methacrylate monomer and initiator in the dropping funnel at a constant speed. In this embodiment, the mixed solution in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com