Technology and device for producing national standard oil through fischer-tropsch synthesis oil and coal tar through hydrogenation

A technology for Fischer-Tropsch synthetic oil and coal tar, applied in the field of coal chemical industry, can solve the problems of low single-pass conversion rate, low diesel yield, small profit margin, etc., and achieve high one-pass conversion rate, low operating cost, and good product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

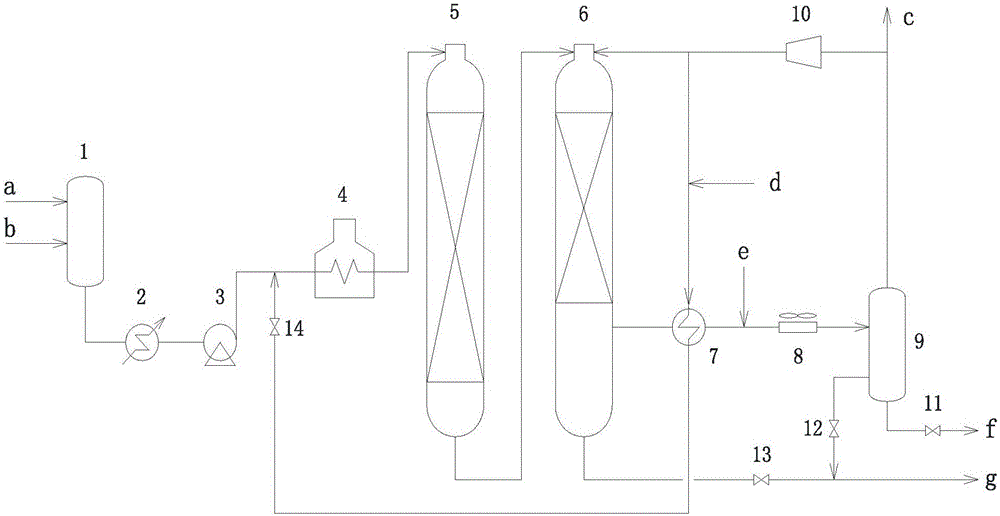

[0046] Fully mix Fischer-Tropsch synthetic oil (low temperature fee) at 70-80°C and coal tar (medium-low temperature or high temperature) at 80-85°C in a mixing tank at a ratio of 0.1-10. The mixing tank is pressurized with hydrogen to 0.8-2.5MPa (gauge pressure) for isolation and sealing. The mixed mixed oil is used as hydrogenation raw material oil, and enters the raw material oil heater through the bottom of the mixing tank to exchange heat with 300°C heat transfer oil to 230-260 After ℃, pressurize to 15.2-19.1MPa (gauge pressure) by the raw oil pump. The pressurized raw material oil and the mixed hydrogen from the high-pressure heat exchanger after heat exchange and temperature rise are mixed in the pipeline and enter the start-up heating furnace. The volume ratio of hydrogen and raw oil is 550-800. During normal operation, the starting heating furnace is in a stuffy state, and the temperature of the raw material oil does not change. The raw material oil from the start-u...

Embodiment 2

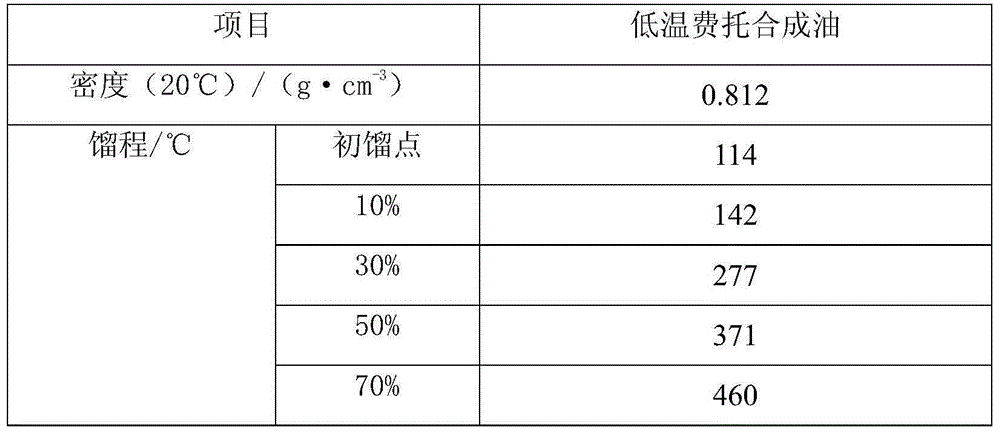

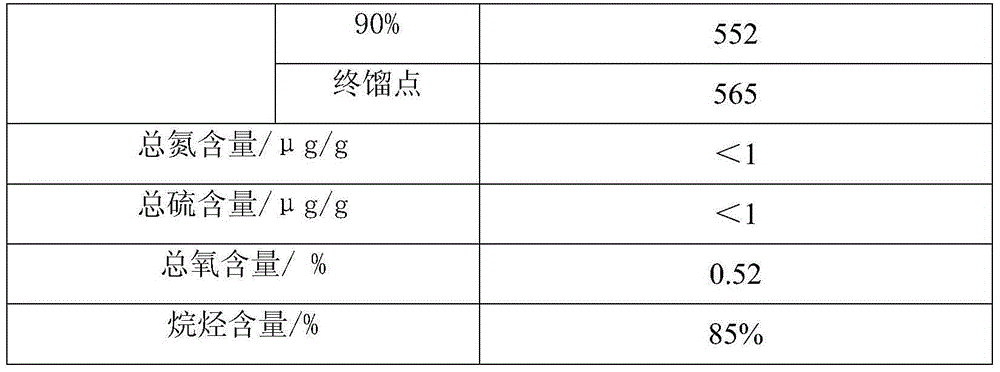

[0054] Fully mix Fischer-Tropsch synthetic oil (low-temperature Fischer-Tropsch synthetic oil) a at 72°C and coal tar (medium-low temperature coal tar) b at 81°C at a ratio of 0.35 in the mixing tank 1, and the mixing tank 1 is pressurized with hydrogen to 1.1MPa (gauge pressure) for isolation and sealing. The mixed mixed oil is used as hydrogenation raw material oil, and enters the raw material oil heater 2 through the bottom of the mixing tank 1 to exchange heat with the 300°C heat transfer oil to 243°C, and then the raw oil pump 3 is used for hydrogenation. Pressure to 16.2MPa (gauge pressure). After the pressurization, the raw material oil and mixed hydrogen are mixed in the pipeline and enter the start-up heating furnace 4, and the volume ratio of the hydrogen gas and the raw material oil is 610. During normal operation, the start-up heating furnace 4 is in a stuffy state, and the temperature of the raw material oil does not change. The raw material oil coming out from t...

Embodiment 3

[0056] The Fischer-Tropsch synthetic oil (low-temperature fee) a of 74 ° C and the coal tar (high-temperature coal tar) b of 85 ° C are fully mixed in the mixing tank 1 at a ratio of 2.1, and the mixing tank 1 is pressurized to 1.46 MPa ( Gauge pressure) for isolation and sealing, the mixed mixed oil is used as the hydrogenation raw material oil, enters the raw material oil heater 2 through the bottom of the mixing tank 1, exchanges heat with the 300°C heat transfer oil to 253°C, and then is pressurized to 17.6MPa by the raw oil pump 3 (Gauge). After the pressurization, the raw material oil and the mixed hydrogen are mixed in the pipeline and enter into the start-up heating furnace 4, and the volume ratio of hydrogen to oil is 721. During normal operation, the start-up heating furnace 4 is in a stuffy state, and the temperature of the raw material oil does not change. The raw material oil coming out from the start-up heating furnace 4 enters the lightening reactor 5 . The op...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap