A kind of calibration method of powder aerosol concentration sensor

The technology of a concentration sensor and a calibration method is applied in the special calibration of the concentration sensor of the powder aerosol and the calibration of the concentration sensor, which can solve the problems of the error of the calibration result, the low flow rate of the powder aerosol, and the waste of the experimental materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Example 1, take N=20, X=20, Y=20, and carry out the calibration test of the powder aerosol concentration sensor

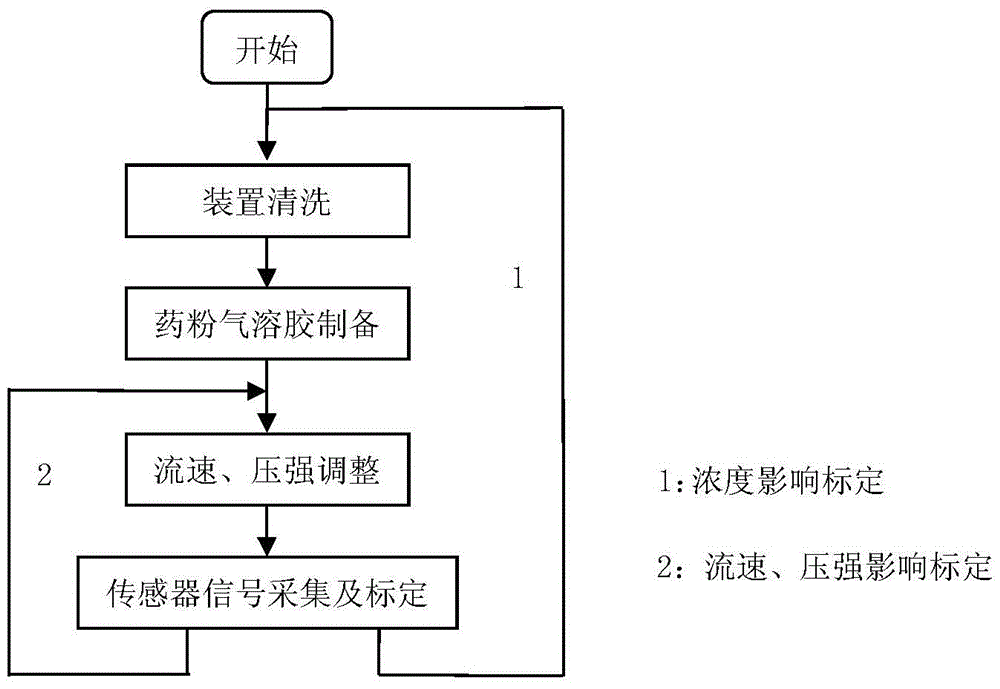

[0047] Such as figure 1 As shown, a calibration method for the concentration sensor of the powder aerosol mainly includes four parts: the device cleaning process, the preparation process of the powder aerosol, the flow rate, the pressure adjustment process, and the signal acquisition and calibration process of the sensor for the concentration sensor of the powder aerosol to be calibrated. Path 1 represents the basic flow of the concentration-affected calibration test of the sensor to be calibrated, and path 2 represents the basic flow of the flow-velocity-affected calibration test and pressure-affected calibration test of the sensor to be calibrated.

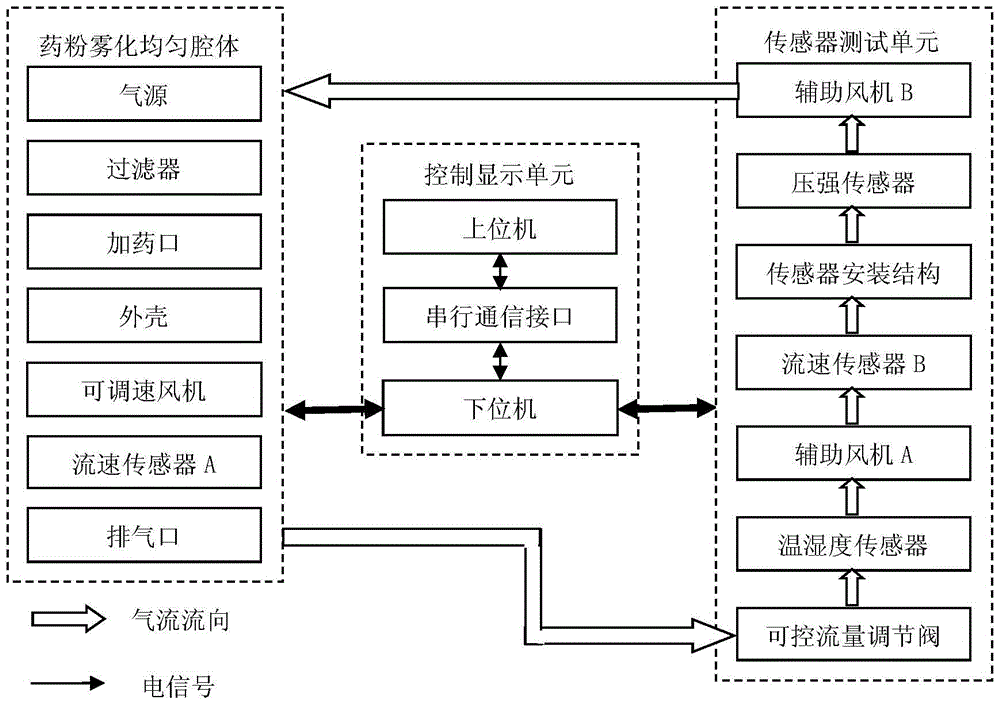

[0048] Such as figure 2As shown, a calibration test device for a drug powder aerosol concentration sensor used to realize the calibration method of a drug powder aerosol concentration sensor according to the...

Embodiment 2

[0064] Example 2, take N=5, X=5, Y=5, and carry out the calibration test of the powder aerosol concentration sensor

[0065] The number of concentration factor calibration groups N=5, the number of flow rate sampling points X=5, and the number of pressure sampling points Y=5, carry out the concentration effect calibration test, flow rate effect calibration test and pressure effect calibration test of the drug powder aerosol concentration sensor to realize the accuracy of the drug powder aerosol Various influencing parameters of the concentration sensor are calibrated, and other details and parameters are the same as those in Embodiment 1.

Embodiment 3

[0066] Embodiment three, take N=50, X=50, Y=50, carry out the calibration test of the powder aerosol concentration sensor, the number of concentration factor calibration groups N=50, the number of flow rate sampling points X=50, the number of pressure sampling points Y=50, carry out the powder The concentration-influenced calibration test, flow-velocity-influenced calibration test and pressure-influenced calibration test of the aerosol concentration sensor realize the calibration of various influencing parameters on the powder aerosol concentration sensor, and the rest of the details and parameters are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com