Emergency rescue method of accident of methylchlorosilane production system

A technology of methyl chlorosilane and emergency rescue, which is applied in the field of emergency response to chemical production accidents, and can solve problems such as reactor overtemperature danger, complex process and equipment, reactor explosion hazard, etc., to reduce casualties and property losses , reduce the risk of injury, the effect of fast emergency response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

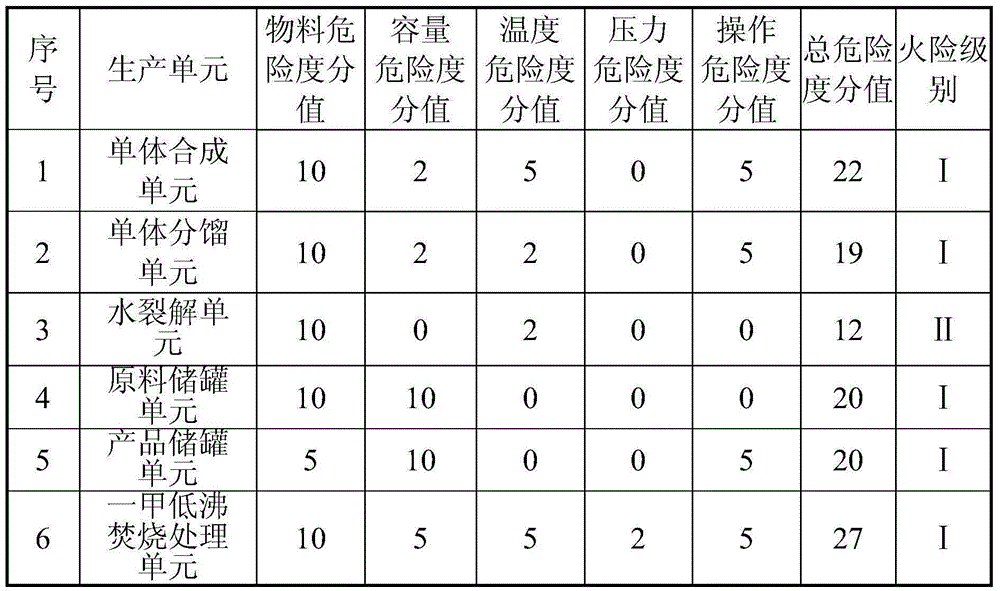

[0057] A single production device, facility or site of the entire methylchlorosilane production system; or several (sets) of production devices, facilities or sites that belong to the same production and business unit and whose edge distance is less than 500m are divided into one production unit.

[0058] The methyl chlorosilane production system is divided into multiple production units, mainly including monomer synthesis unit, monomer fractionation unit, water cracking unit, raw material storage tank unit, product storage tank unit, and a low-boiling incineration treatment unit. The raw material storage tank unit includes methyl chloride storage tank, methanol storage tank, etc. The product storage tank unit includes first-class storage tanks, second-class storage tanks, third-class storage tanks, first-class hydrogen storage tanks, etc.

[0059] The monomer synthesis unit is the core unit of the organosilicon production system. Silicon powder and catalyst copper powder are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com