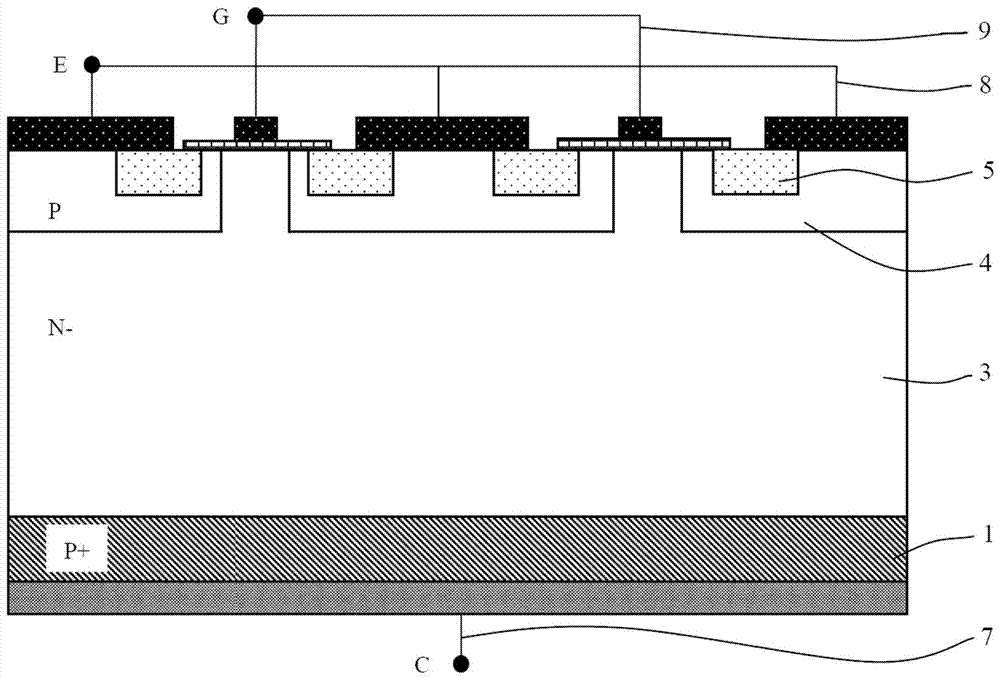

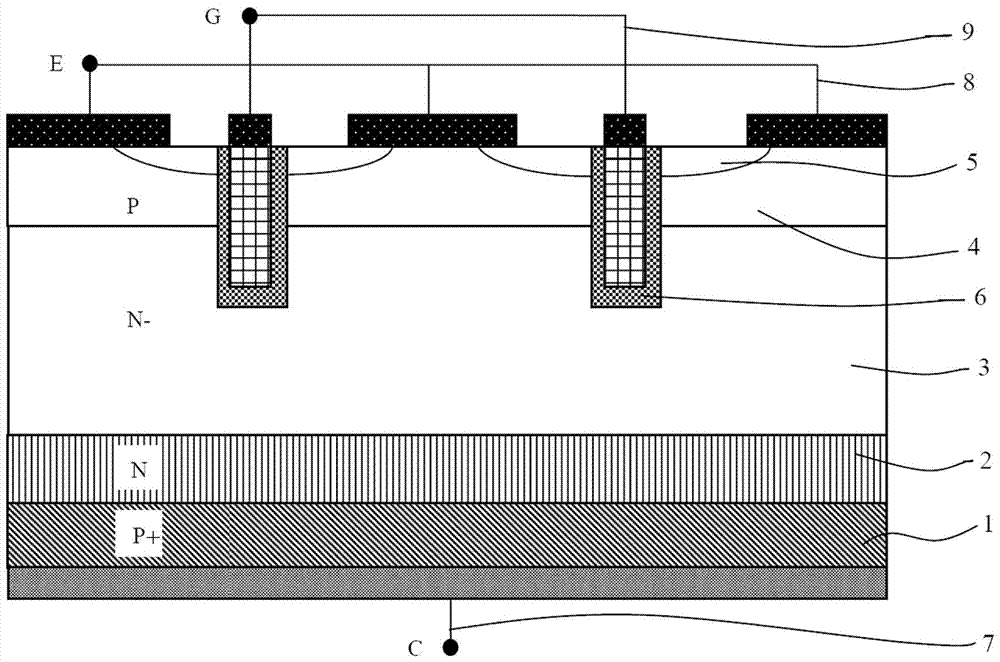

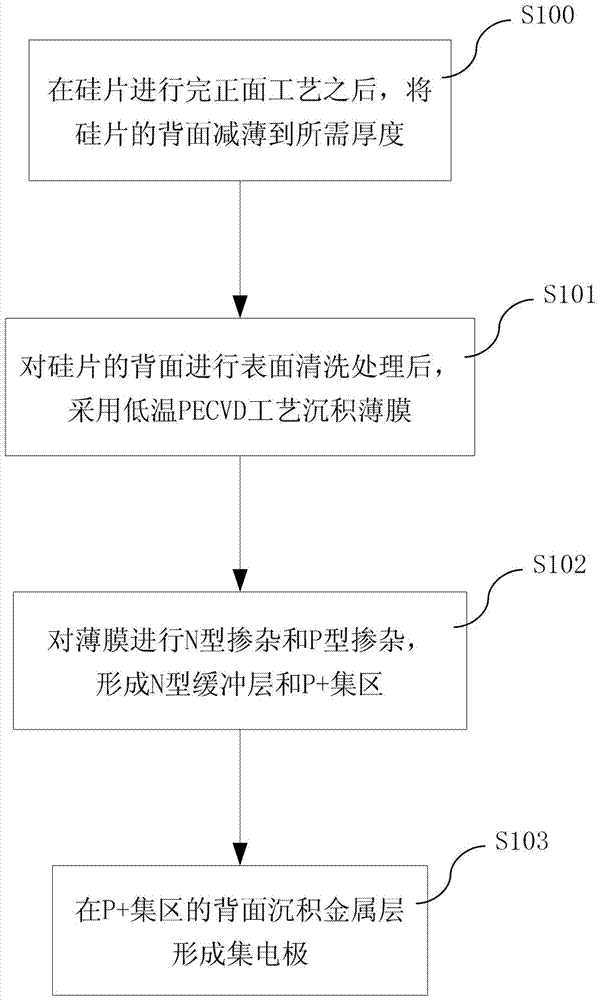

Semiconductor device with buffer layer and manufacturing method thereof

A manufacturing method and semiconductor technology, applied in the fields of semiconductor devices, semiconductor/solid-state device manufacturing, transistors, etc., can solve the problems of reducing the thermal budget, inability to achieve, and difficult to avoid high temperature annealing process, etc., to reduce the thermal budget, save equipment costs, The effect of reducing the turn-on voltage drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] For the sake of reference and clarity, the technical terms, abbreviations or abbreviations used below are recorded as follows:

[0042] IGBT: Insulated Gate Bipolar Transistor, short for insulated gate bipolar transistor;

[0043] NPT: Non-Punch Through, the abbreviation of non-punch through;

[0044] E: Emitter, the abbreviation of emitter;

[0045] G: Gate, the abbreviation of gate;

[0046] C: Collector, short for collector;

[0047] MOS: Metal Oxid Semiconductor, the abbreviation of Metal Oxide Semiconductor;

[0048] PECVD: Plasma Enhanced Chemical Vapor Deposition, the abbreviation of plasma enhanced chemical vapor deposition;

[0049] DMOS: double-diffused MOSFET, the abbreviation of double-diffused metal oxide semiconductor field effect transistor.

[0050]In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention will be clearly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com