Novel superimposed perovskite solar cell preparation method

A solar cell and perovskite technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of high process cost, expensive price, and inability to meet large-scale large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

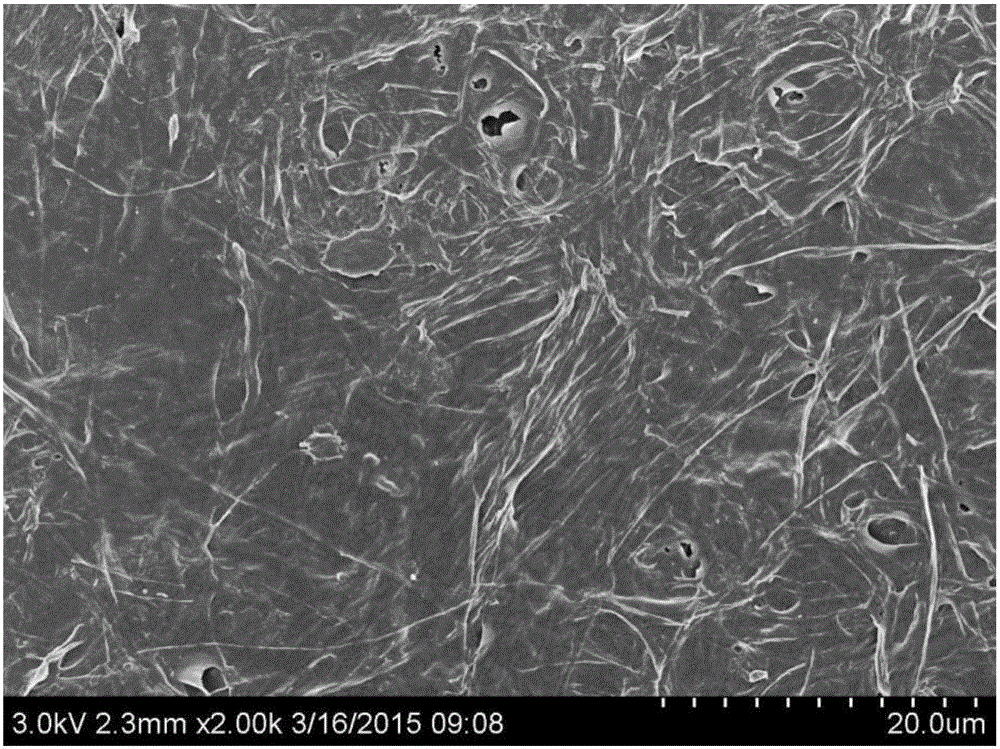

[0046] Weigh 40 mg of PEDOT:PSS granules, add 5 ml of isopropanol, and then add some zirconium beads and put them together in a desktop disperser for ball milling at a frequency of 35 Hz for 4 hours. After ball milling, pipette 250uL of the mixture of PEDOT:PSS and isopropanol with a pipette gun, and spray the mixture evenly onto the prepared Spiro-MeOTAD film with a spray gun in a thermal spraying method at a spraying temperature of 95°C. Then pipette 500uL of the mixture of PEDOT:PSS and isopropanol with a pipette gun, and spray the mixture evenly on the FTO glass substrate with a spray gun in a thermal spraying method, and the spraying temperature is 95°C. The surface morphology of PEDOT:PSS film obtained by ball milling method, such as figure 1 shown. Then assemble the device and test the photoelectric performance, at AM1.5, 100mW / cm 2 Use KEITHLEY 4200 to test the I-V performance curve of the battery under light, and the short-circuit current density of the battery is 1...

Embodiment 2

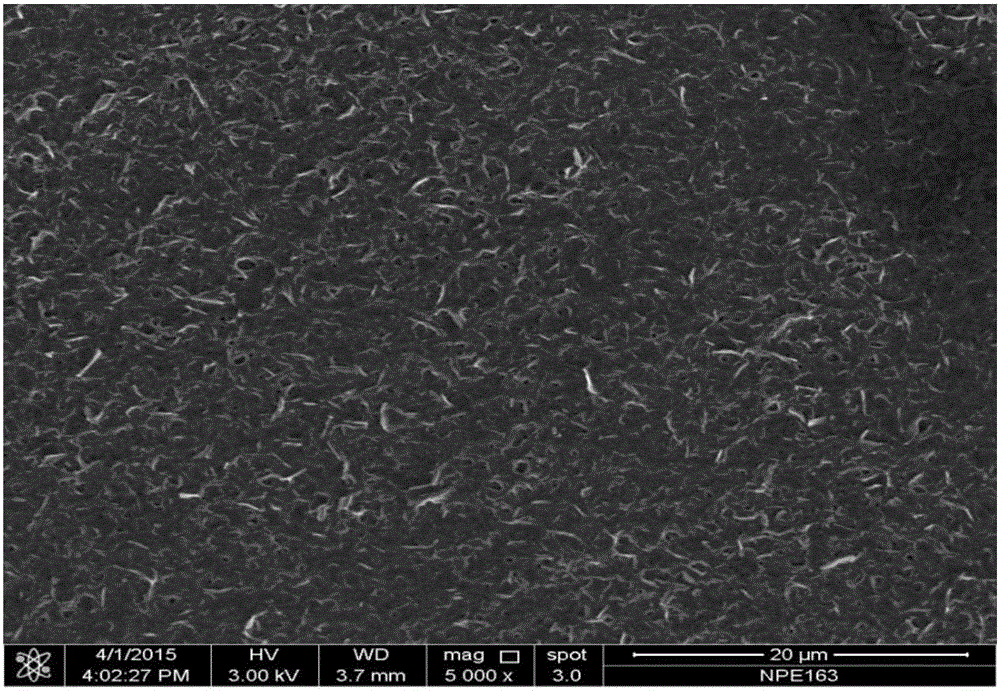

[0048] Weigh 40 mg of PEDOT:PSS granules, add 5 ml of isopropanol, and carry out mixing and dispersion under the condition of ultrasonic vibration, the frequency of ultrasonic vibration is 35 Hz, and the time is 2 h. After oscillating, pipette 250uL of the mixture of PEDOT:PSS and isopropanol with a pipette gun, and spray the mixture evenly onto the prepared Spiro-MeOTAD membrane with a spray gun in a thermal spraying method at a spraying temperature of 95°C. Then pipette 500uL of the mixture of PEDOT:PSS and isopropanol with a pipette gun, and spray the mixture evenly on the FTO glass substrate with a spray gun in a thermal spraying method, and the spraying temperature is 95°C. The surface morphology of PEDOT:PSS film obtained by ultrasonic oscillation method, such as figure 2 shown. Then assemble the device and test the photoelectric performance, at AM1.5, 100mW / cm 2 Use KEITHLEY 4200 to test the I-V performance curve of the battery under light, and the short-circuit curr...

Embodiment 3

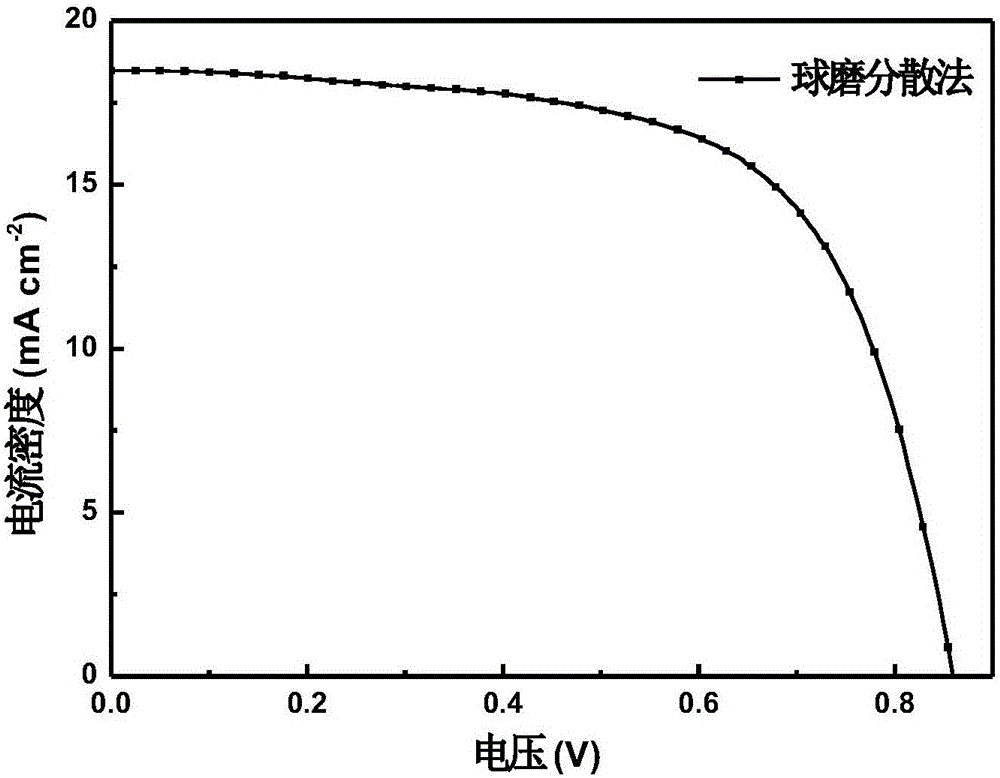

[0050] Weigh 40 mg of PEDOT:PSS granules, add 5 ml of isopropanol, and then add some zirconium beads and place them together in a desktop disperser for ball milling at a frequency of 45 Hz for 3 hours. After ball milling, use a pipette gun to pipette different amounts of mixtures of PEDOT:PSS and isopropanol, and spray the mixture evenly onto the prepared Spiro-MeOTAD film by thermal spraying with a spray gun at a spraying temperature of 65°C . Then pipette 500uL of the mixture of PEDOT:PSS and isopropanol with a pipette gun, and spray the mixture evenly on the FTO glass substrate with a spray gun in a thermal spraying method, and the spraying temperature is 65°C. Then assemble the device and test the photoelectric performance, at AM1.5, 100mW / cm 2 Use KEITHLEY 4200 to test the I-V performance curve of the battery under light, such as Figure 5 As shown, when the layer I spraying amount is 125uL, the short-circuit current density of the battery is 17.88mA / cm 2 , the open ci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com