A kind of industrial sewage treatment system and sewage treatment method

A sewage treatment method and technology of a treatment system, which are applied in the field of environmental protection water treatment, can solve the problems of secondary environmental pollution, hidden environmental risks of sewage temporary storage pools, and inability to achieve effective separation and utilization of sewage substances, so as to achieve convenient and reliable use and reduce Influence and damage, reasonable effect of structural composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

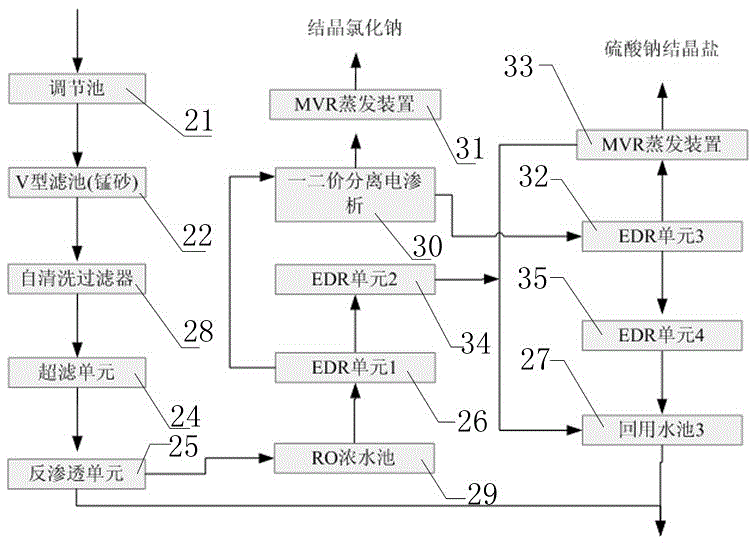

[0065] figure 2 As shown, the sewage treatment system used in the present invention mainly includes: "ultrafiltration + reverse osmosis + frequent reverse electrode electrodialysis system (EDR) + one-two price separation electrodialysis system (ED) + frequent reverse electrode electrodialysis system (EDR) +MVR evaporation device"

[0066] The effluent from the sewage treatment plant enters the reclaimed water unit regulating tank 21, and is homogenized and evenly measured and then lifted into the V-shaped filter 22. The suspended solids and colloidal substances in the sewage are removed by sand filtration. The V-shaped filter uses special filter media. , Has the function of removing cobalt and manganese ions. Sand filtration effluent enters "ultrafiltration + reverse osmosis + frequent reversed electrodialysis system (EDR) + primary and secondary separation electrodialysis system (ED) + frequent reversed electrodialysis system (EDR) + MVR evaporation device", ultrafiltration uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com