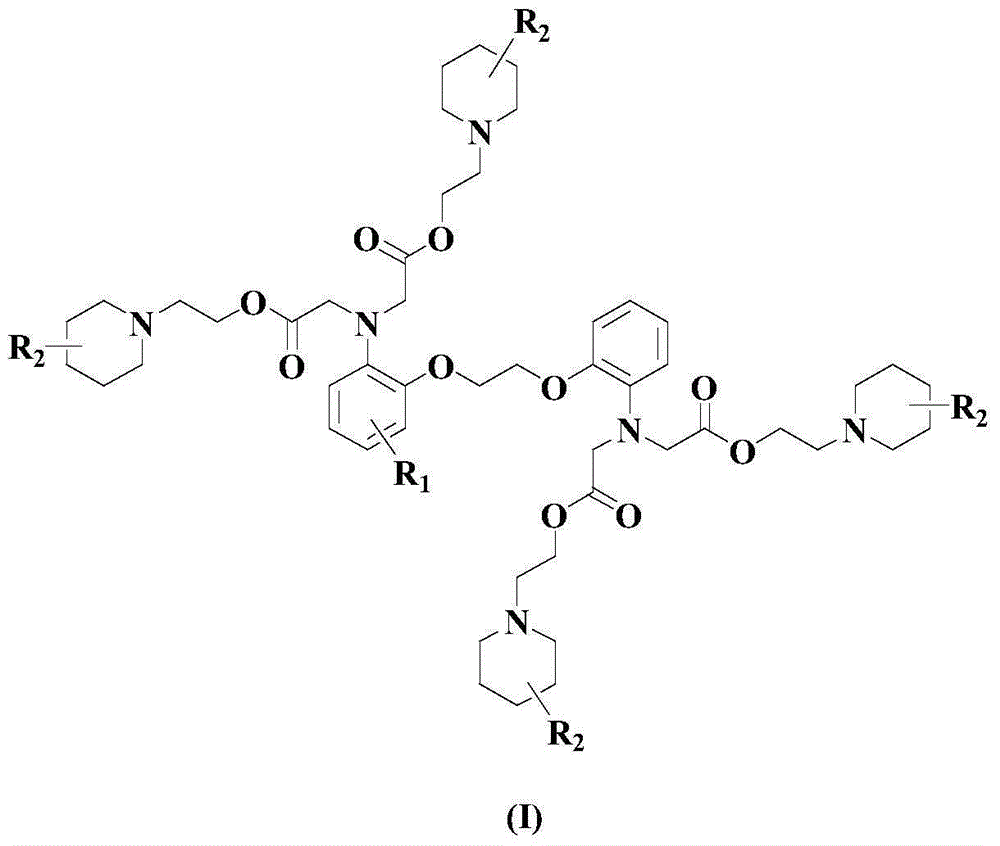

Novel calcium-ion selective chelating agent and preparation method and application thereof

A calcium ion, selective technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, drug combinations, etc. Achieve the effect of good industrial production potential, excellent biological activity, and good yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0056] Preparation Example 1: Preparation of Catalyst C1

[0057] (1) SBA-15 mesoporous molecular sieves were calcined at 500°C for 40 minutes, and then naturally cooled to room temperature to obtain primary treated molecular sieves;

[0058] (2) placing the primary treated molecular sieve in a water vapor atmosphere at 500° C. for 60 minutes to obtain a secondary treated molecular sieve;

[0059] (3) Add secondary treatment molecular sieve and ionic liquid N,N,N',N'-tetramethyl-N,N'-disulfonic acid propylpropylenediamine bisulfate to an appropriate amount of ethyl acetate (where , the mass of the secondary treatment molecular sieve and N,N,N',N'-tetramethyl-N,N'-disulfonic acid propylpropylenediamine bisulfate is 1:0.4), at 40°C Thoroughly stir and mix for 8 hours, then filter, wash the resulting solid with deionized water 2-3 times, and then vacuum-dry to obtain catalyst C1.

preparation example 2

[0060] Preparation Example 2: Preparation of Catalyst C2

[0061] (1) SBA-15 mesoporous molecular sieves were calcined at 520°C for 30 minutes, and then naturally cooled to room temperature to obtain primary treated molecular sieves;

[0062] (2) placing the primary treated molecular sieve in a water vapor atmosphere at 500°C for 70 minutes to obtain a secondary treated molecular sieve;

[0063] (3) Add the secondary treatment molecular sieve and ionic liquid N,N,N',N'-tetramethyl-N,N'-disulfonic acid propylpropylenediamine bisulfate into an appropriate amount of chloroform (wherein, the The mass ratio of the secondary treatment molecular sieve to N,N,N',N'-tetramethyl-N,N'-disulfonic acid propylpropylenediamine bisulfate is 1:0.5), fully Stir and mix for 6 hours, then filter, wash the resulting solid with deionized water for 2-3 times, and then vacuum-dry to obtain catalyst C2.

preparation example 3

[0064] Preparation Example 3: Preparation of Catalyst C3

[0065] (1) SBA-15 mesoporous molecular sieves were calcined at 550°C for 20 minutes, and then naturally cooled to room temperature to obtain primary treated molecular sieves;

[0066] (2) placing the primary treated molecular sieve in a water vapor atmosphere at 500°C for 80 minutes to obtain a secondary treated molecular sieve;

[0067] (3) Add the secondary treatment molecular sieve and ionic liquid N,N,N',N'-tetramethyl-N,N'-disulfonic acid propyl propylene diamine bisulfate into an appropriate amount of benzene (wherein, the The mass ratio of the secondary treatment molecular sieve to N,N,N',N'-tetramethyl-N,N'-disulfonic acid propylpropylenediamine bisulfate is 1:0.6), fully Stir and mix for 4 hours, then filter, wash the resulting solid with deionized water for 2-3 times, and then vacuum-dry to obtain catalyst C3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com