Method for co-producing epoxypropane and furoic acid

A technology of propylene oxide and furoic acid, applied in the production of bulk chemicals, organic chemistry, etc., can solve the problems of difficult control of the reaction system, easy deactivation of catalysts, etc., and achieve easy separation, high selectivity, and simplified separation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

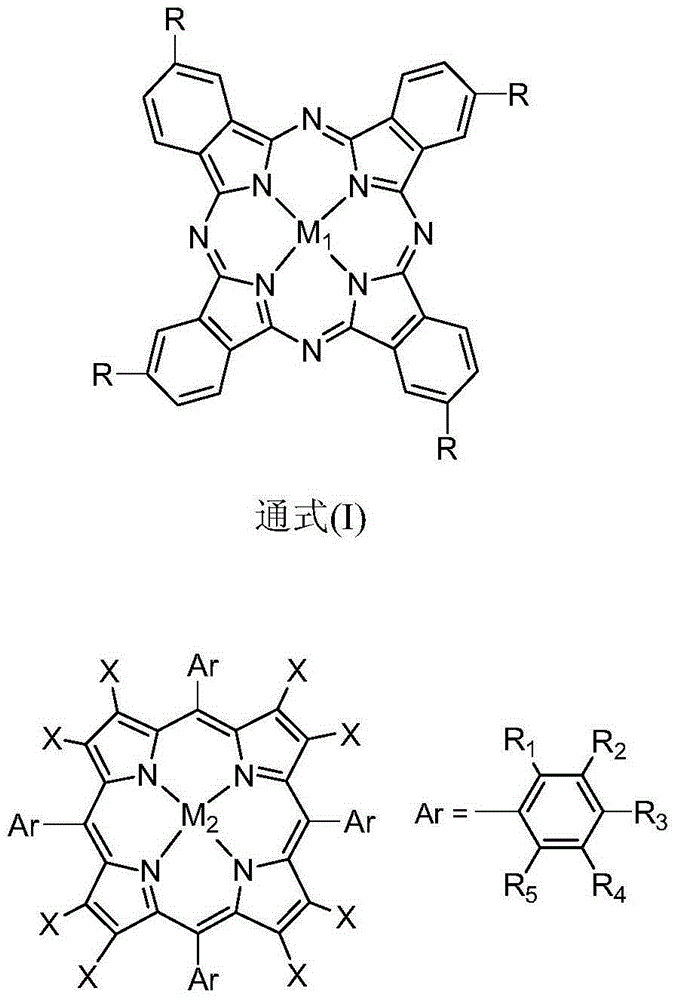

[0022] Contain 0.1mmol cobalt phthalocyanine in 25mL (R=H in general formula (I), M 1 =Co) in the acetonitrile solution of 0.01mol, add 0.01mol of furfural, charge respectively 0.8MPa of propylene and 1.2MPa of oxygen, and carry out stirring reaction at a temperature of 30°C. Through chromatographic analysis, the conversion rate of propylene is 15%, and furfural The conversion rate of 75%, the selectivity of propylene oxide is 84%, the yield of furoic acid is 75%.

Embodiment 2

[0024] Contains 1.0 x 10 in 25mL -3 mmol tetracarboxy copper phthalocyanine (R=COOH in general formula (I), M 1 =Cu) in the acetonitrile solution of Cu), add 5.0mmol furfural, be charged with the oxygen of propylene of 0.1MPa and 0.2MPa respectively, carry out stirring reaction under 50 ℃ at temperature, through chromatographic analysis, the conversion rate of propylene is 38%, the conversion rate of furfural The conversion rate was 85%, the selectivity of propylene oxide was 90%, and the yield of furoic acid was 85%.

Embodiment 3

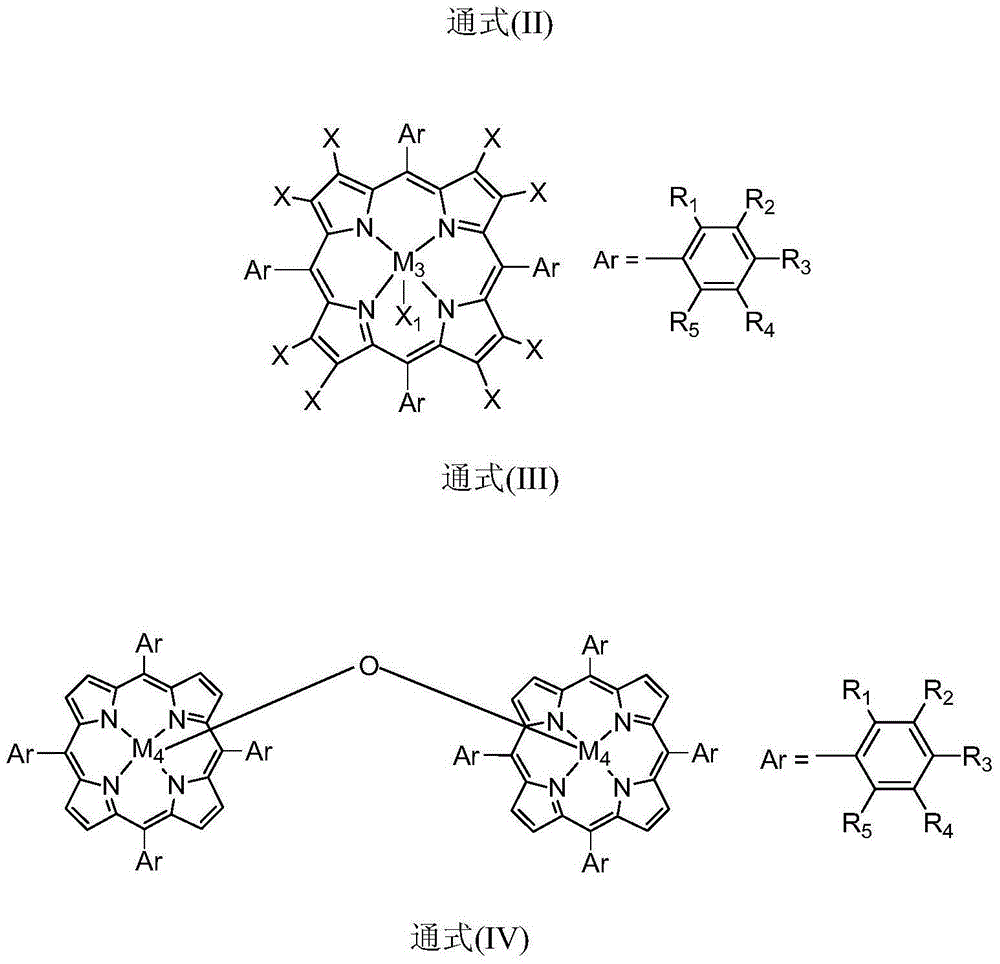

[0026] Contains 1.0×10 in 50mL -3 mmol o-chlorotetraphenyliron porphyrin (R in general formula (II) 1 =Cl,R 2 =R 3 =R 4 =R 5 =H,M 2 =Fe, X=H) in 1,2-dichloroethane solution, add 0.1mol of furfural, respectively fill in 0.8MPa of propylene and 2.2MPa of oxygen, and carry out stirring reaction at a temperature of 90°C. Analysis showed that the conversion rate of propylene was 30%, the conversion rate of furfural was 78%, the selectivity of propylene oxide was 91%, and the yield of furoic acid was 78%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com