Self-skinning compound material for heat-resistant polyurethane foaming tyre and preparation method thereof

A technology of polyurethane and heat resistance, which is applied in special tires, tire parts, transportation and packaging, etc., can solve problems that are rarely reported, and achieve the effect of improving heat resistance, excellent performance, and expanding the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

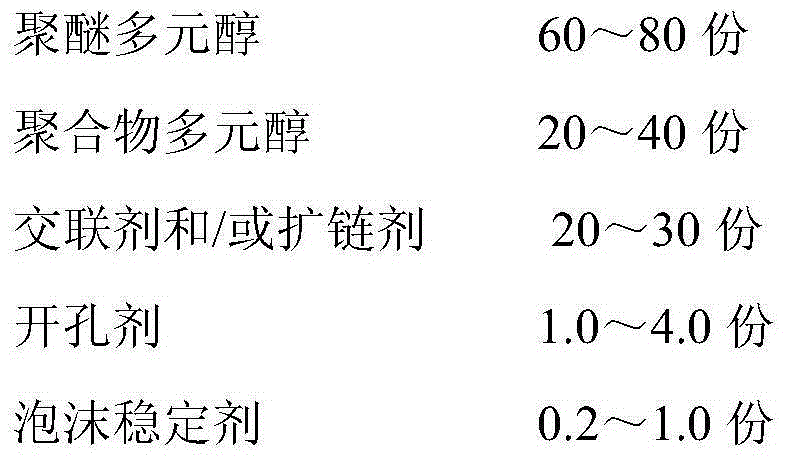

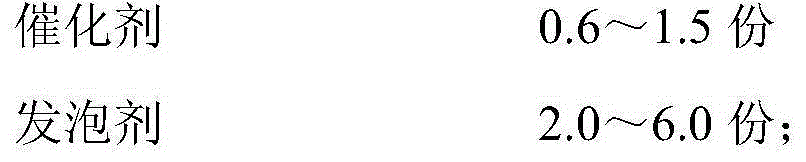

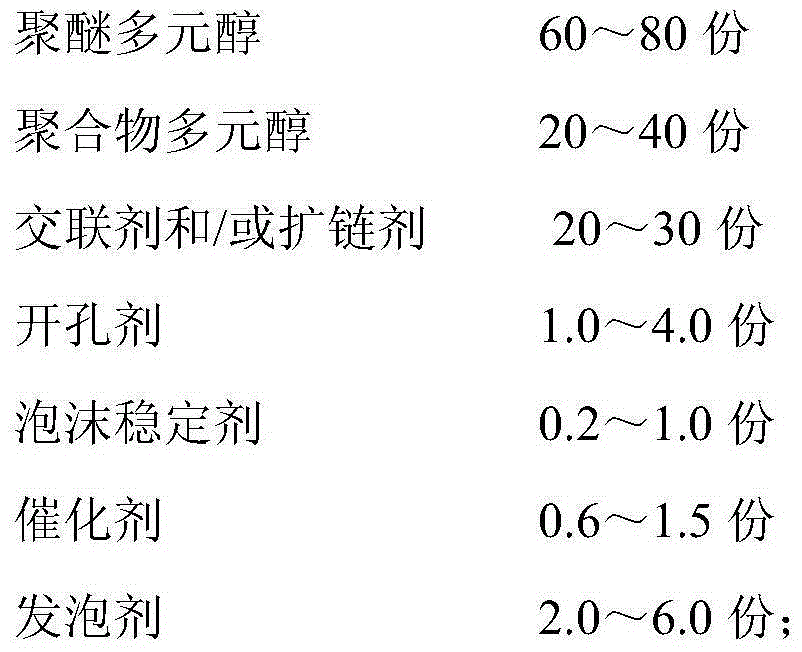

Method used

Image

Examples

Embodiment 1

[0034] Component A: Weigh 80kg of polyether polyol (EP-330NG, product of Shandong Bluestar Dongda Chemical Co., Ltd.), 20kg of polymer polyol (POP93 / 28, product of Shandong Bluestar Dongda Chemical Co., Ltd.), 1 , 4-butanediol 13kg, ethylene glycol 4kg, diethylene glycol 4kg, cell opening agent (DK-12, product of Shandong Bluestar Dongda Chemical Co., Ltd.) 3kg, organosilicon foam stabilizer DC193 (American gas chemical products Co., Ltd.) 0.3kg, MOCA (Suzhou Xiangyuan Fine Chemical Co., Ltd.) 1kg, tertiary amines and organotin catalysts (A-33 and T-12) 0.5kg and 0.1kg respectively, blowing agent HCFC-141B 4kg, placed in a reaction kettle, mixed evenly, discharged, sealed and stored;

[0035] Component B: Weigh 100kg of polyester polyol (PE2420, product of Shandong Yinuowei Polyurethane Co., Ltd.), keep the temperature at 55°C, add 210kg of 4,4-diphenylmethane diisocyanate, heat up to 77°C and keep warm for reaction After 1.2 hours, 20 kg of carbonized diimide-modified MDI wa...

Embodiment 2

[0038] Component A: Weigh 60kg of polyether polyol (EP-3600, product of Shandong Bluestar Dongda Chemical Co., Ltd.), 40kg of polymer polyol (POP36 / 28, product of Shandong Bluestar Dongda Chemical Co., Ltd.) The sum of ether polyol and polymer polyol 100), 1,4-butanediol 13kg, ethylene glycol 6kg, MOCA (Suzhou Xiangyuan Fine Chemical Co., Ltd.) 3kg, cell opener (DK-12, Shandong Lanxingdong Da Chemical Co., Ltd.) 1kg, organosilicon foam stabilizer DC193 (American Gas Chemical Products Co., Ltd.) 1.5kg, tertiary amines and equilibrium catalysts (A-33 and C-225) were 0.9kg and 0.4kg, respectively. Foaming agent HCFC-141B 4kg, placed in the reaction kettle, mixed evenly, discharged, sealed for storage.

[0039] Component B: Weigh 100kg of polyester polyol (PE2420, product of Shandong Yinuowei Polyurethane Co., Ltd.), keep the temperature at 60°C, add 200kg of 4,4-diphenylmethane diisocyanate, heat up to 80°C and keep warm for reaction For 1 hour, add 40 kg of carbonized diimide-m...

Embodiment 3

[0042]Component A: Weigh 70kg of polyether polyol (EP-330NG, product of Shandong Bluestar Dongda Chemical Co., Ltd.), 30kg of polymer polyol (POP93 / 28, product of Shandong Bluestar Dongda Chemical Co., Ltd.), 1 , 4-butanediol 19kg, ethylene glycol 3kg, MOCA (Suzhou Xiangyuan Fine Chemical Co., Ltd.) 5kg, cell opening agent (DK-12, product of Shandong Bluestar Dongda Chemical Co., Ltd.) 5kg, silicone foam Agent AK-7703 (Shanghai Demei Shichuang Co., Ltd.) 0.8kg, tertiary amines and equilibrium catalysts (A-33 and C-225) were 0.9kg and 0.6kg respectively, blowing agent HCFC-141B 4kg, placed in the reaction In the kettle, after mixing evenly, discharge the material and keep it sealed.

[0043] Component B: Weigh 100kg of polyester polyol (PE2420, product of Shandong Yinuowei Polyurethane Co., Ltd.), keep the temperature at 50°C, add 170kg of 4,4-diphenylmethane diisocyanate, heat up to 75°C and keep warm for reaction After 1.5 hours, 50 kg of carbonized diimide-modified MDI was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com