Applied film

A technology of coating film and coating liquid, which is applied in the field of coating film, can solve problems such as easy curling or slack, and achieve the effects of preventing oligomer precipitation, high industrial use value, and excellent appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

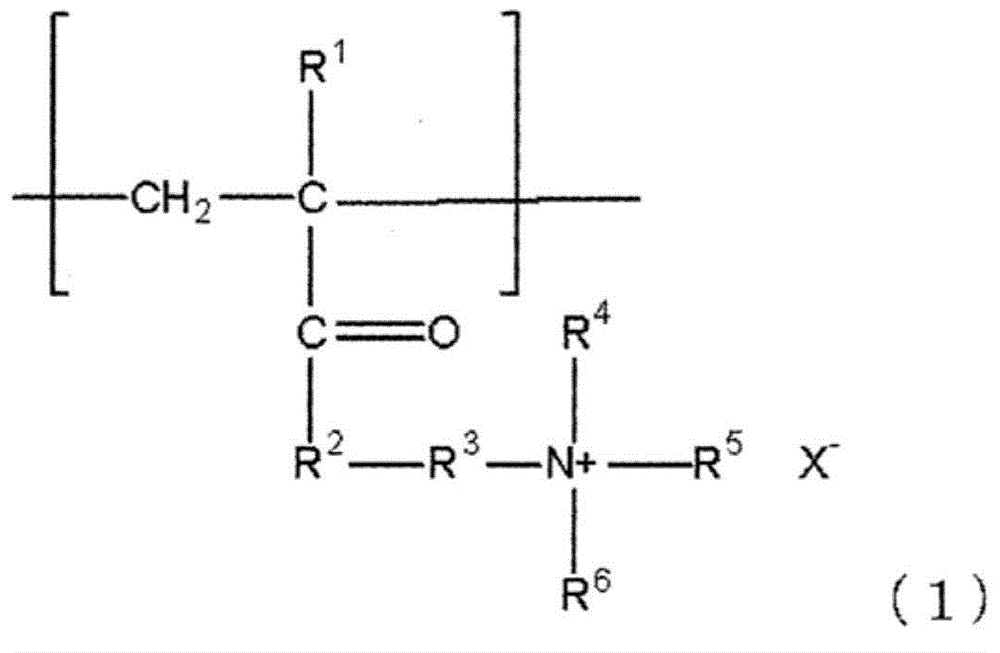

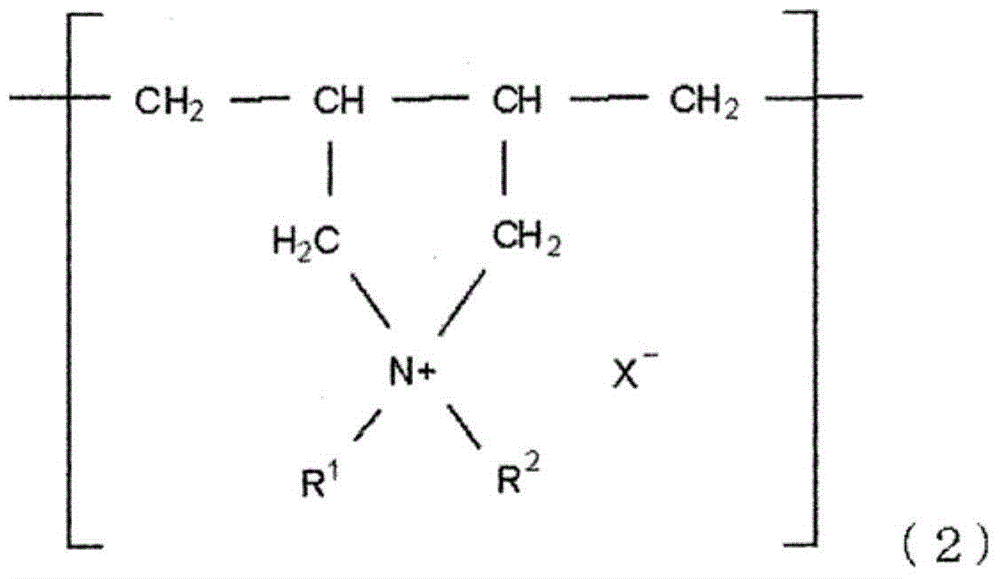

Method used

Image

Examples

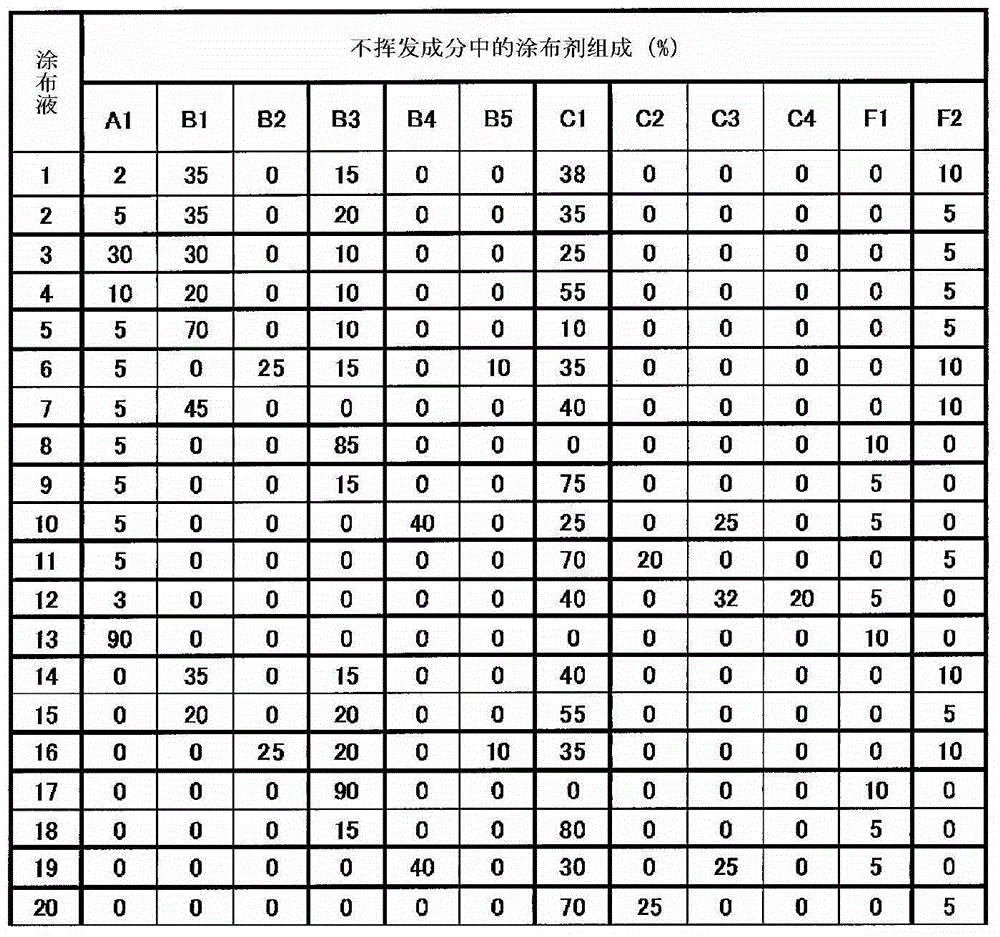

Embodiment 1

[0152] The mixture of polyester (B) and (E) blended in a weight ratio of 80 / 20 is used as the raw material of the surface layer, and only the polyester (A) is used as the raw material of the middle layer, which are respectively supplied to two extruders, After heating to 285°C and melting, layer A is used as the outermost layer (surface layer), layer B is used as the middle layer, and two types of three layers (A / B / A) are co-extruded to form a thickness ratio of A / B / A =4 / 117 / 4, using the electrostatic adhesion method, making it adhere to a mirror-faced cooling roll with a surface temperature of 40-50° C., cooling and solidifying it, and producing an unstretched polyethylene terephthalate film. After the film was stretched 3.4 times in the longitudinal direction by using the difference in the circumferential speed of the rollers while passing through a set of heating rollers at 85°C, the water-based coating shown in Table 1 below was applied to one side of the longitudinally str...

Embodiment 2~13

[0155] In Example 1, except having changed the coating agent composition into the coating agent composition shown in Table 1, it manufactured similarly to Example 1, and obtained the polyester film. The obtained polyester film had the characteristics shown in Table 3, and the film haze increase value (ΔH) due to the heat treatment was small, and the precipitation amount of the ester cyclic trimer was small, which was good.

Embodiment 14

[0157] In Example 1, the polyester film was obtained by the same method as in Example 1 except that the thickness composition ratio was set to A / B / A=5 / 178 / 5, and the thickness of the polyester film was changed to 188 μm. . Table 3 shows the properties of the obtained polyester film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com