Low-temperature SO2-resistant MnxSby/PG-type SCR denitration catalyst and preparation method thereof

A denitrification catalyst and catalyst technology, applied in the direction of physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve problems such as high energy consumption and complex processes, and achieve strong adsorption ability, low cost, good thermal stability and formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: The denitration catalyst described in this embodiment has the following main components:

[0031] Active component: manganese nitrate, 8 parts by weight;

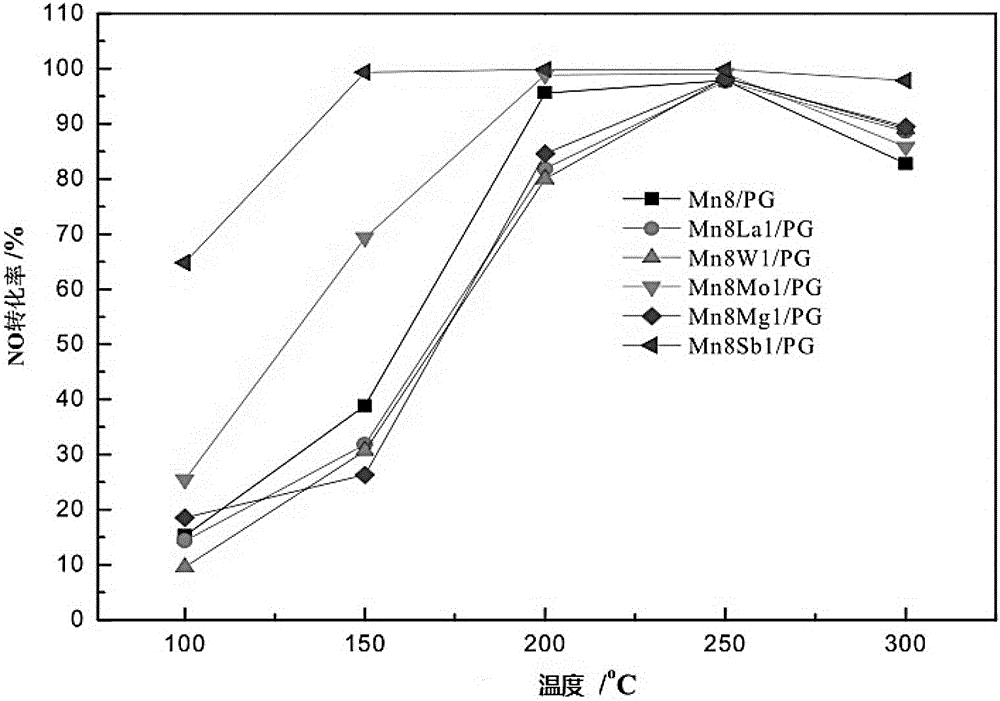

[0032] Add metal: one of Sb, Mo, La, W and Mg, 1 part by weight;

[0033] Carrier: attapulgite (PG), 100 parts by weight.

[0034] The preparation method of the denitration catalyst is as follows:

[0035] (1) Weigh manganese nitrate and another metal acetate according to the ratio of Mn:M=8:1 (M is one of Sb, Mo, La, W and Mg), and dissolve them in a mass concentration of 50 % citric acid solution, make MnO x and another metal oxide accounted for 4wt% and 0.5wt% of the catalyst respectively, and after the solution was fully dissolved, they were mixed into an active solution for later use;

[0036](2) Select attapulgite PG of 20-40 mesh as the carrier, add 92wt% PG, water, and ammonia water with a mass concentration of 15% to the mixer at a speed of 100rpm, and then add 0.5% at a mass ratio of 1:5 ...

Embodiment 2

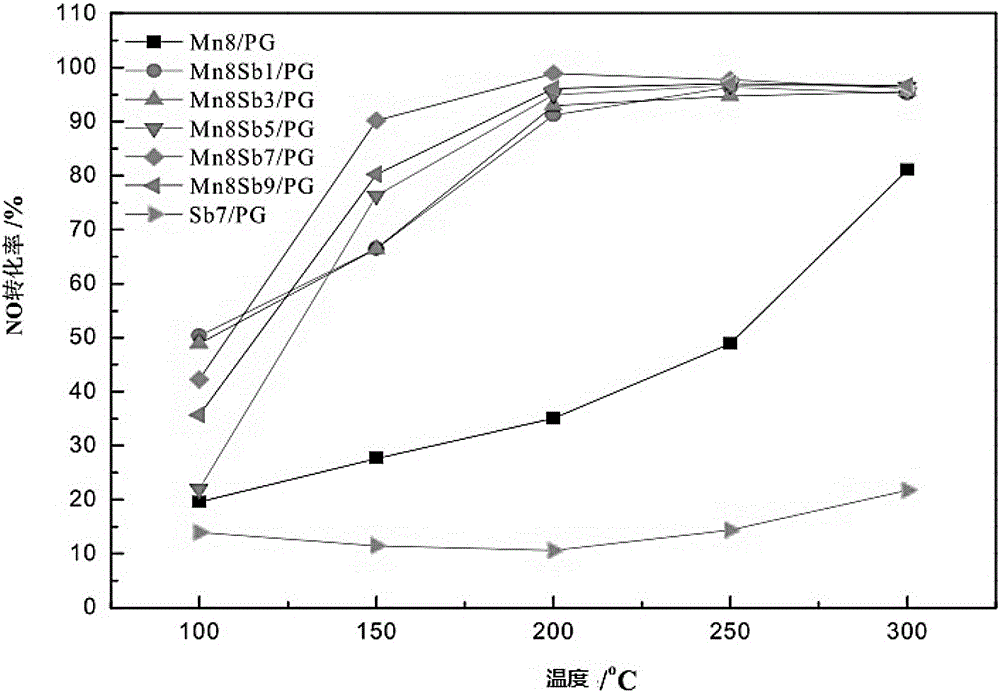

[0042] Embodiment 2: The denitration catalyst described in this embodiment has the following main components:

[0043] Active ingredient: manganese nitrate, 8 parts by weight;

[0044] Add metal: Sb, respectively 0, 1, 3, 5, 7, 9 parts by weight;

[0045] Carrier: attapulgite (PG).

[0046] The preparation method of the denitration catalyst is as follows:

[0047] (1) Weigh a certain amount of manganese nitrate and antimony acetate according to Mn:Sb=8:x (x is 0, 1, 3, 5, 7, 9), and dissolve them in citric acid solution with a mass concentration of 50% , making MnO x and Sb 2 o 5 Accounting for 4wt% of the catalyst, (0, 0.5, 1.5, 2.5, 3.5, 4.5)wt%, respectively, after the solution is fully dissolved, mix it into an active solution for later use;

[0048] (2) (2) Select 20-40 mesh attapulgite PG as the carrier, add (92.5, 92, 91, 90, 89, 88) wt% of PG, water, and ammonia water with a mass concentration of 15% at a speed of 100rpm Put down the mixer, then add 0.5wt% stear...

Embodiment 3

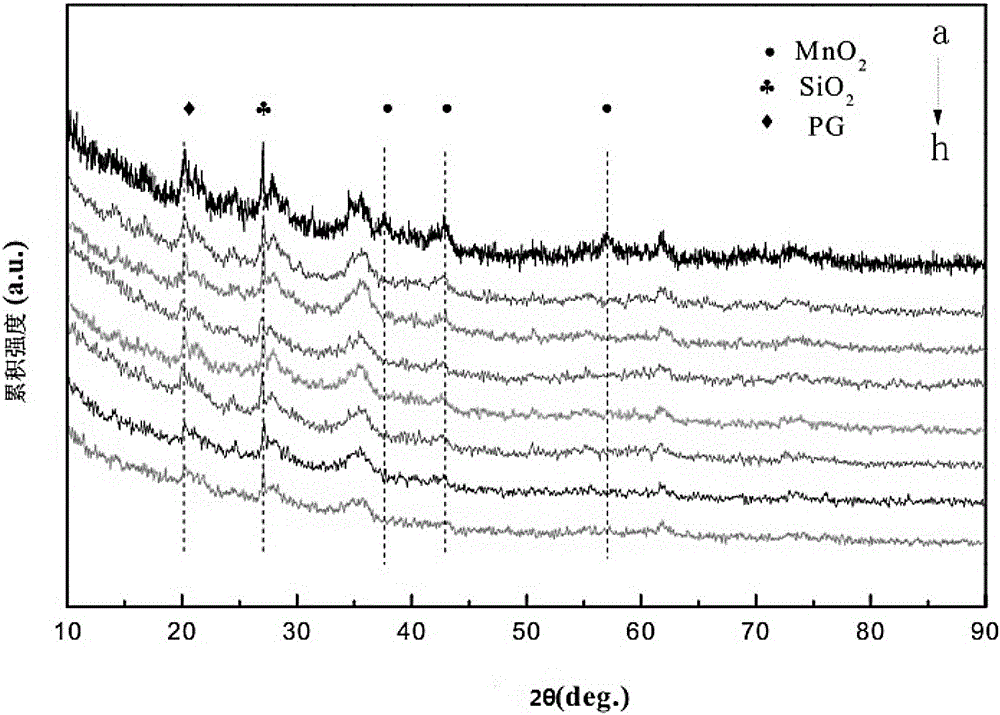

[0055] A series of Mn prepared in embodiment 2 8 Sb x / PG (x=0, 1, 3, 5, 7, 9) catalysts were analyzed by XRD and obtained image 3 . Such as image 3 As shown, all catalysts show MnO at 2θ=37.6, 42.8, 57.0 2 characteristic diffraction peaks. Antimony-based catalysts and Mn 8 / PG exhibited lower peaks, which could be assigned to the nature of small grains forming solids. In addition, when the antimony content continues to increase, the corresponding MnO 2 The characteristic peaks at 2θ = 37.6, 42.8, and 57.0 weaken order, indicating that manganese oxides are gradually highly dispersed on the catalyst surface, and manganese oxide crystal structures have been proposed to improve the presence of oxygen vacancies and enhance catalyst performance. Furthermore, for all catalysts, no antimony oxide crystallites were detected, which indicated that antimony oxide was highly dispersed on the surface of the PG support.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com