Degradable non-woven fabric glue dipping composite preparation technology and materials thereof

A composite process, non-woven technology, applied in synthetic resin layered products, lamination devices, lamination auxiliary operations, etc., can solve problems such as good moisture permeability, increase wear resistance and tear resistance, tear resistance Excellent performance, the effect of delaying or stopping the spread of flames

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

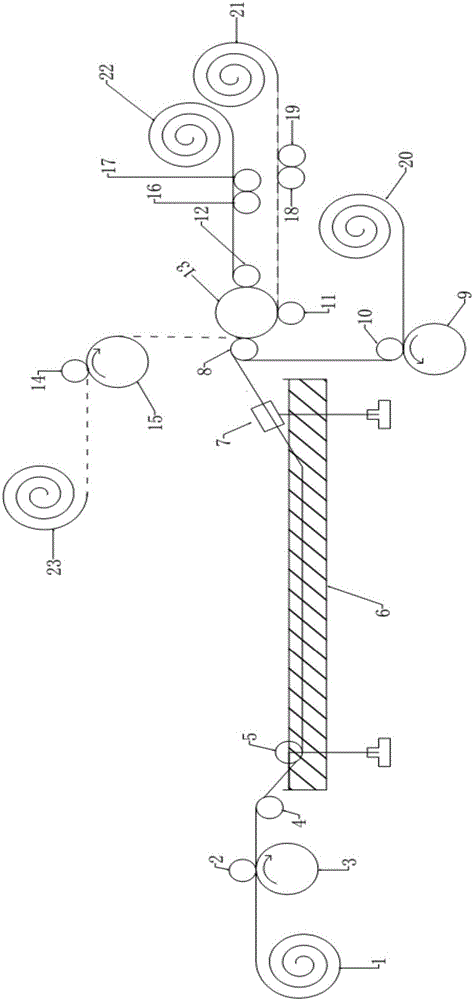

Image

Examples

Embodiment 1

[0031] The method for preparing composite material of the present invention specifically comprises the following steps:

[0032] Step 1, first prepare a certain size of PVA non-woven fabric, the size of which can be changed according to the device matched with it, then prepare a PVA colloidal solution with a PVA mass fraction of 10%, and place the colloidal solution in a metal tray;

[0033] Step 2. Arrange the PVA nonwovens of the selected size on the unwinding frame, pass through the tension control device and the deviation correction device, and then enter the metal disc box containing the PVA colloidal solution, and pass the temperature control under the metal disc box The device controls the temperature in the metal disc box to 60°C, and a scraper is installed on the side of the PVA non-woven fabric facing away from the metal disc box;

[0034] Step 3. The PVA non-woven fabric passes through at a speed of 10m / min and is immersed in the metal disc box. When it moves to the s...

Embodiment 2

[0039] The method for preparing composite material of the present invention specifically comprises the following steps:

[0040] Step 1, first prepare a certain size of PVA non-woven fabric, the size of which can be changed according to the device matched with it, then prepare a PVA colloidal solution with a PVA mass fraction of 12%, and place the colloidal solution in a metal tray;

[0041] Step 2. Arrange the PVA nonwovens of the selected size on the unwinding frame, pass through the tension control device and the deviation correction device, and then enter the metal tray containing the PVA colloidal solution, and pass the temperature control under the metal tray. The device controls the temperature in the metal disc box to 80°C, and a scraper is installed on the side of the PVA non-woven fabric facing away from the metal disc box;

[0042] Step 3. The PVA non-woven fabric passes through at a speed of 10m / min and is immersed in the metal disc box. When it moves to the scrape...

Embodiment 3

[0046] The method for preparing composite material of the present invention specifically comprises the following steps:

[0047] Step 1, first prepare a certain size of PVA non-woven fabric, its size can be changed according to the device matched with it, and then the mass fraction of PVA is 15%, the mass fraction of plasticizer glycerol is 3.5%, and the mass fraction of stearic acid is prepared. 0.8% PVA colloidal solution, the colloidal solution is placed in a metal tray;

[0048] Step 2. Arrange the PVA nonwovens of the selected size on the unwinding frame, pass through the tension control device and the deviation correction device, and then enter the metal tray containing the PVA colloidal solution, and pass the temperature control under the metal tray. The device controls the temperature in the metal disc box to 70°C, and a scraper is installed on the side of the PVA non-woven fabric facing away from the metal disc box;

[0049] Step 3. The PVA non-woven fabric passes th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peel strength | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com