The preparation method of stannous sulfide nano sheet

A stannous sulfide and nanosheet technology, applied in chemical instruments and methods, nanotechnology, nanotechnology and other directions, can solve the problems of easy oxidation reaction process, low purity, low yield, etc., and achieve simple method and high sample purity. , the effect of large output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

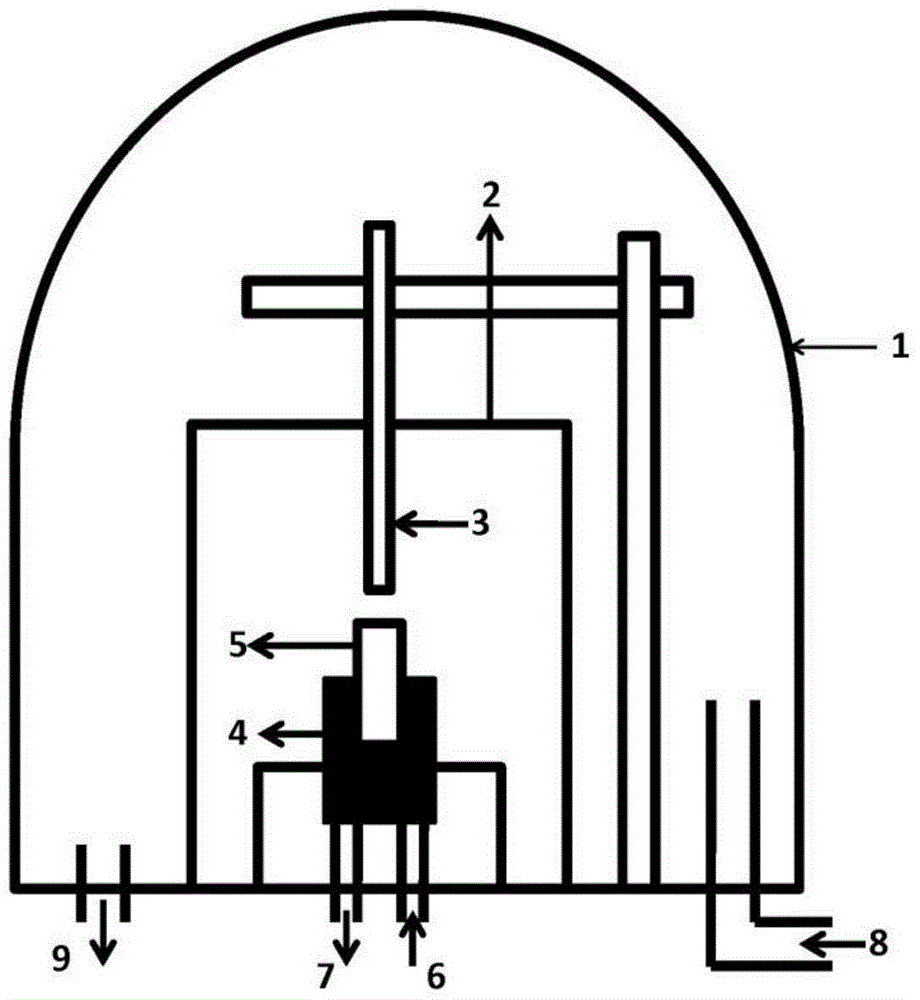

[0024] Put 200-mesh tin (Sn) powder and sulfur (S) powder into the mixer at a molar ratio of 1:1 and mix evenly. Take out 4g of mixed powder, use a tablet press to press into a cylinder with a diameter of 1.8cm and a height of 0.5cm, specifically a density of 4g / cm 3 briquettes of mixed powder. Put the briquette of the pressed mixed powder into the graphite pot, and then put it into the anode in the reaction chamber of the DC arc discharge device. The anode of the DC arc discharge device is a copper pot (a graphite pot is placed in the copper pot as an anode), the cathode is a tungsten electrode, and the tungsten rod cathode is placed opposite to the anode of the copper pot. Evacuate the reaction chamber of the DC arc discharge device into a vacuum (less than 5pa), and then fill it with argon gas at 20kPa (atmospheric pressure). The copper pot is fed with circulating cooling water and starts to discharge. During the discharge process, keep the voltage at 30V, the current at...

Embodiment 2

[0027] Put the 200-mesh Sn powder and S powder into the mixer according to the molar ratio of 1:1 and mix them evenly. Take out 4g of the mixed powder, use a tablet press to briquette, and press it into a cylinder with a diameter of 1.8cm and a height of 0.5cm, specifically a briquette of the mixed powder with a density of 4.5g / cm3. Put the briquette of the pressed mixed powder into the graphite pot, and then put it into the anode in the reaction chamber of the DC arc discharge device. The anode of the arc discharge device is a copper pot (a graphite pot is placed in the copper pot as an anode), the cathode is a tungsten rod electrode, and the tungsten rod cathode is placed opposite to the anode of the copper pot. Evacuate the reaction chamber of the DC arc discharge device into a vacuum (less than 5pa), and then fill it with argon gas at 5kPa (atmospheric pressure). The copper pot is fed with circulating cooling water and starts to discharge. During the discharge process, t...

Embodiment 3

[0029] Put the 200-mesh Sn powder and S powder into the mixer according to the molar ratio of 1:1 and mix them evenly. Take out 5g of mixed powder, use a tablet press to briquette, and press it into a cylinder with a diameter of 3cm and a height of 3cm, specifically a density of 5g / cm 3 briquettes of mixed powder. Put the briquette of the pressed mixed powder into the graphite pot, and then put it into the anode in the reaction chamber of the DC arc discharge device. The anode of the arc discharge device is a copper pot (a graphite pot is placed in the copper pot as an anode), the cathode is a tungsten rod electrode, and the tungsten rod cathode is placed opposite to the anode of the copper pot. Evacuate the reaction chamber of the DC arc discharge device into a vacuum (less than 5pa), and then fill it with argon gas at 30kPa (atmospheric pressure). The copper pot is fed with circulating cooling water and starts to discharge. During the discharge process, the voltage is kept...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com