A kind of treatment method of oil product refining waste lye

A treatment method and technology of waste lye, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems that are not used as inspection indicators, and achieve reduction of reagent usage, Effect of reducing phenol concentration and COD and realizing zero discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

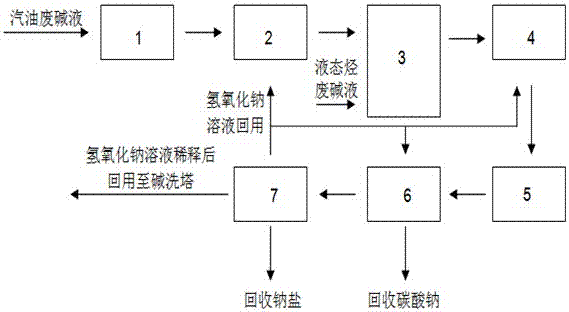

Image

Examples

Embodiment 1

[0034] A stream of gasoline waste lye, its COD is 536000mg / L, S 2- The concentration is 12700mg / L, the concentration of phenol is 196000mg / L, the concentration of sodium carbonate is 23760mg / L, the concentration of sodium hydroxide is 2.6wt%, and the concentration of oil is 190mgL. A stream of liquid hydrocarbon waste lye containing organic nitrogen, its COD is 179000mg / L, the concentration of organic nitrogen is 8730mg / L, S 2- The concentration is 35800mg / l, the concentration of phenol is 32300mg / L, the concentration of sodium carbonate is 10800mg / L, the concentration of sodium hydroxide is 3.5wt%, and the concentration of oil is 150mg / L. Adopt the inventive method to process under the following conditions:

[0035] (1) Acidification and neutralization: Add concentrated sulfuric acid to gasoline waste lye, when the pH value of waste lye is 3-4, stop adding acid, stir for 30 minutes, and stand still for 24 hours. After the acidification treatment, the waste lye is divided in...

Embodiment 2

[0043] A stream of gasoline waste lye, its COD is 396800mg / L, S 2- The concentration is 9360mg / l, the concentration of phenol is 147000mg / L, the concentration of sodium carbonate is 18390mg / L, the concentration of sodium hydroxide is 2.9wt%, and the concentration of oil is 173mgL. A stream of liquid hydrocarbon waste lye containing organic nitrogen, its COD is 158200mg / L, the concentration of organic nitrogen is 7240mg / L, S 2- The concentration is 29320mg / l, the concentration of phenol is 28240mg / L, the concentration of sodium carbonate is 9920mg / L, the concentration of sodium hydroxide is 3.8wt%, and the concentration of oil is 135mg / L. Adopt the inventive method to process under the following conditions:

[0044] (1) Acidification and neutralization: add concentrated sulfuric acid to the waste gasoline lye, when the pH value of the waste lye is 5-6, stop adding acid, stir for 30 minutes, and stand still for 24 hours. After the acidification treatment, the waste lye is divi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com