Method for preparing environmentally friendly reclaimed rubber by two-stage desulfurization

A reclaimed rubber, environmental protection technology, applied in the direction of recycling technology, plastic recycling, etc., can solve the problems of poor mechanical properties such as tensile strength, large damage degree of rubber carbon chain, and small damage degree of rubber carbon chain, etc., to achieve tensile strength Good mechanical properties, good processing performance, and less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

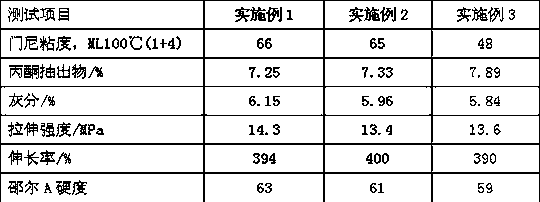

Embodiment 1

[0018] The waste rubber powder selected is the rubber powder of the carcass rubber of the waste radial tire.

[0019] One-stage high-temperature desulfurization: add 100 parts of 28-mesh tire rubber powder; 1 part of activator 450; 220°C, pressure 2.1MPa, heat desulfurization for 120min, turn off the heating power, do not keep warm, directly exhaust and relieve pressure, stop stirring, open the tank door, discharge, cool to about 50°C, and obtain a section of high-temperature desulfurization reclaimed rubber.

[0020] Two-stage low-temperature desulfurization: introduce the reclaimed rubber that has been desulfurized at a high temperature and cooled to about 50°C into the mixer, add 1 part of low-temperature desulfurization regenerant RV rubber regenerant, stir for 10 minutes, and then introduce it into the rubber double-roller mill. For 30 minutes, the thin pass conditions are roll temperature 50°C, roll distance 0.1 mm, and the second-stage desulfurization environmentally fr...

Embodiment 2

[0023] The waste rubber powder selected is the rubber powder of the carcass rubber of the waste radial tire.

[0024] One-stage high-temperature desulfurization: add 100 parts of 28-mesh tire rubber powder; 1.5 parts of activator 450; 1.5 parts of rosin; 30 parts of tap water into the desulfurization tank, stir and heat at a stirring speed of 30 rpm, and heat up the material gradually To 210°C, pressure 1.85MPa, heat and desulfurize for 105min, turn off the heating power, do not keep warm, directly exhaust the pressure, stop stirring, open the tank door, discharge the material, cool to about 50°C, and obtain a section of high-temperature desulfurized reclaimed rubber.

[0025] Two-stage low-temperature desulfurization: introduce the reclaimed rubber that has been desulfurized at a high temperature and cooled to about 50°C into the mixer, add 1.5 parts of low-temperature desulfurization regenerant RV rubber regenerant, stir for 25 minutes, and then introduce it into the rubber m...

Embodiment 3

[0028] The waste rubber powder selected is the rubber powder of the carcass rubber of the waste radial tire.

[0029] One-stage high-temperature desulfurization: 100 parts of 28-mesh tire rubber powder; 2 parts of activator 450; 2 parts of rosin; 200°C, pressure 1.7MPa, heat desulfurization for 90 minutes, turn off the heating power, do not keep warm, directly exhaust and relieve pressure, stop stirring, open the tank door, discharge, cool to about 50°C, and obtain a section of high-temperature desulfurization reclaimed rubber.

[0030] Two-stage low-temperature desulfurization: introduce the reclaimed rubber that has undergone high-temperature desulfurization and cooled to about 50°C into the mixer, add 2 parts of low-temperature desulfurization regenerant RV rubber regenerant, stir for 30 minutes, and then introduce it into the rubber double-roller mill. For 15 minutes, the thin pass conditions are roll temperature 80°C, roll distance 0.3 mm, and the second-stage desulfuriza...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com