Oil well cement thixotropic agent and preparation method thereof

A technology of oil well cement and thixotropic agent, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of temperature sensitivity, weak comprehensive performance, weak thixotropy, etc., and achieve improvement of thixotropy and comprehensive performance good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] An oil well cement thixotropic agent provided by an embodiment of the present invention includes: ultrafine clay and an amphoteric polymer, and the mass ratio of the ultrafine clay to the amphoteric polymer is 10:1.

[0041] In this example, the amphoteric polymer is a tetrapolymer synthesized by aqueous radical polymerization.

[0042] Specifically, the tetrapolymer includes: acrylamide, 2-acrylamido-2-methylpropanesulfonic acid, acrylic acid and a cationic monomer, and acrylamide, 2-acrylamido-2-methylpropanesulfonic acid The weight ratio of acid, acrylic acid and cationic monomer is: 35-80 parts of acrylamide, 10-50 parts of 2-acrylamido-2-methylpropanesulfonic acid, 5-15 parts of acrylic acid, 5-5 parts of cationic monomer 30 servings.

[0043] In this embodiment, the cationic monomer is dimethyl diallyl ammonium chloride, acryloyloxyethyl trimethyl ammonium chloride or octadecyl dimethyl allyl ammonium chloride.

Embodiment 2

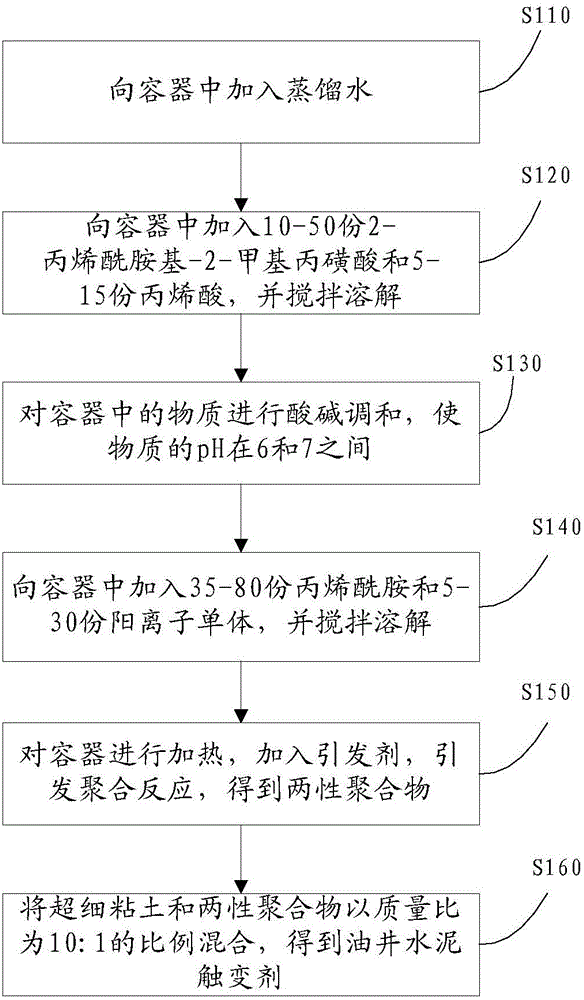

[0045] see figure 1 , the preparation method of the oil well cement thixotropic agent provided by the embodiment of the present invention, the method is used to prepare the above-mentioned oil well cement thixotropic agent, comprising:

[0046] Step S110: adding distilled water to the container;

[0047] Step S120: Add 10-50 parts of 2-acrylamido-2-methylpropanesulfonic acid and 5-15 parts of acrylic acid into the container, and stir to dissolve;

[0048] Step S130: adjusting the acid-base of the substance in the container, so that the pH of the substance is between 6 and 7;

[0049] To illustrate this step, step S130 specifically includes:

[0050] Add sodium hydroxide solution to the container to acid-base the substance so that the substance has a pH between 6 and 7.

[0051] Step S140: Add 35-80 parts of acrylamide and 5-30 parts of cationic monomer into the container, and stir to dissolve;

[0052] The embodiment of the invention is specifically described:

[0053] Af...

Embodiment 3

[0065] Weigh 15 parts of 2-acrylamido-2-methylpropanesulfonic acid and 5 parts of acrylic acid into a beaker with an appropriate amount of distilled water, and stir to dissolve. Then sodium hydroxide solution was added dropwise to adjust the pH of the system to 6.5, and the mixture was poured into a cleaned three-necked bottle. Add 70 parts of acrylamide and 10 parts of cationic monomer, fill with nitrogen, and start stirring. After all the monomers are dissolved, turn on the heating device to heat the mixed solution in the three-necked bottle. When the temperature of the system reaches 35°C, add 0.5 part of initiator to initiate the polymerization reaction. After reacting in a constant temperature water bath at 50°C for 4-6 hours, a gel-like viscous substance was obtained. The synthetic colloidal viscous material is granulated, dried, and ground to obtain a solid granular product, and the ultrafine clay and the solid granular product are mixed uniformly with a mass ratio of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com