A method for high-yield cellulase utilizing Trichoderma fungus

A technology of cellulase and Trichoderma, which is applied in the field of high-yield cellulase using Trichoderma fungus, can solve problems affecting the popularization and application of cellulase, increase the cost of cellulase, increase production costs, etc., and achieve improved induction effect , Enzyme system structure is perfect, the effect of saving production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

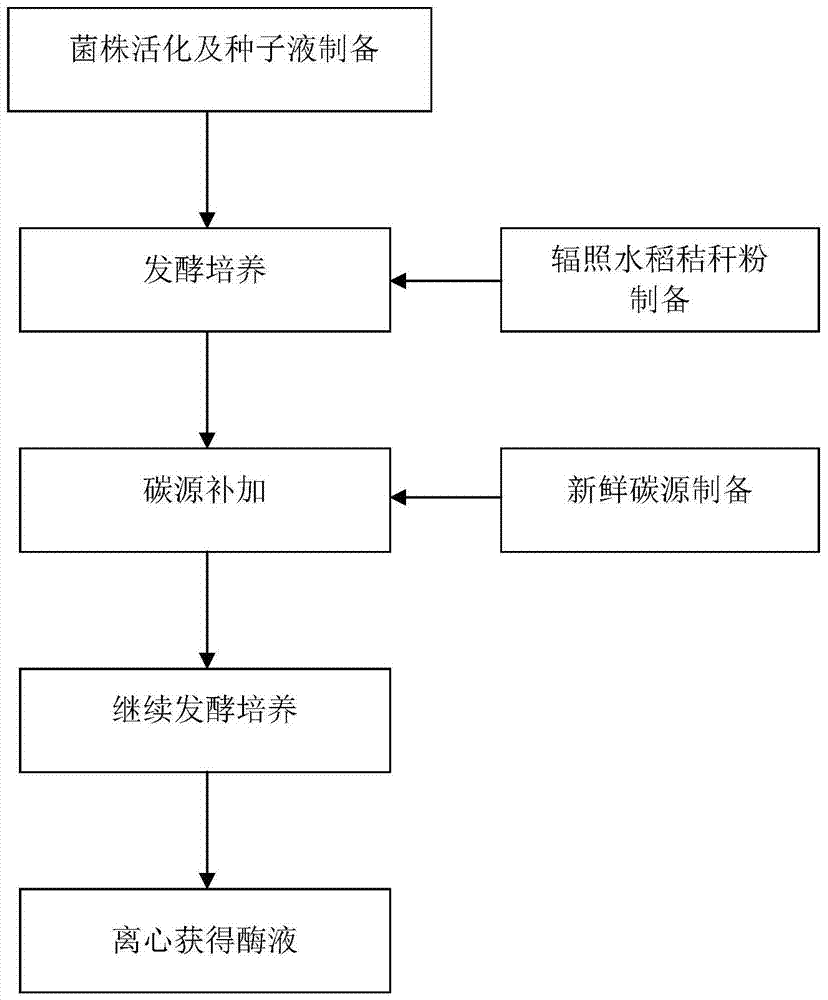

[0045] a kind of like figure 1 Shown utilizes the method for Trichoderma viride (Trichoderma viride) high-yield cellulase, comprises the following steps:

[0046] (1) The spores of Trichoderma viride were inoculated on the PDA plate culture medium in a sterile environment, cultured with shaking at 30° C. for 96 hours, and then a ring was picked and inoculated in the seed medium. The production process of the seed medium is as follows: cut 200g of potatoes into small pieces, add 800ml of water, boil for 30min, filter with gauze, add 20g of glucose after the filtrate is cooled, dilute to 1L, and sterilize at 120°C for 15min. The shaker culture was carried out in the seed medium, and the temperature was 30° C., and the rotation speed was 130 r / min. The shaker was cultured for 48 hours, and the seed liquid was obtained after the shaker culture.

[0047](2) Insert the seed liquid obtained in step (1) into the fermented enzyme production medium according to the amount of 5% of the ...

Embodiment 2

[0058] a kind of like figure 1 Shown utilize Trichoderma reesei (Trichoderma reesei) high-yield cellulase method, comprises the following steps:

[0059] (1) The spores of Trichoderma reesei were inoculated on a PDA plate culture medium under a sterile environment, cultured with shaking at 28° C. for 96 hours, and then a loop was picked and inoculated in the seed medium. The production process of the seed medium is as follows: cut 200g of potatoes into small pieces, add 800ml of water, boil for 30min, filter with gauze, add 20g of glucose after the filtrate is cooled, dilute to 1L, and sterilize at 120°C for 15min. The shaker culture was carried out in the seed medium, and the temperature was 28° C., and the rotation speed was 130 r / min. The shaker was cultured for 48 hours, and the seed liquid was obtained after the shaker culture.

[0060] (2) Insert the seed solution obtained in step (1) into the fermented enzyme production medium according to the insertion amount of 4%, a...

Embodiment 3

[0071] a kind of like figure 1 Shown utilizes Trichoderma koningi (Trichoderma koningi) high-yield cellulase method, comprises the following steps:

[0072] (1) The spores of Trichoderma konii were inoculated on a PDA plate medium for culture in a sterile environment, cultured with shaking at 30° C. for 96 hours, and then a loop was picked and inoculated in the seed medium. The production process of the seed medium is as follows: cut 200g of potatoes into small pieces, add 800ml of water, boil for 30min, filter with gauze, add 20g of glucose after the filtrate is cooled, dilute to 1L, and sterilize at 120°C for 15min. The shaker culture was carried out in the seed medium, and the temperature was 30° C., and the rotation speed was 130 r / min. The shaker was cultured for 48 hours, and the seed liquid was obtained after the shaker culture.

[0073] (2) Insert the seed solution obtained in step (1) into the fermented enzyme production medium according to the amount of 6% of the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com