Low-cost normalizing rolling hot rolling H type steel and preparation method thereof

A technology of normalizing rolling and H-shaped steel, which is applied in the field of low-cost normalizing rolling and hot-rolled H-shaped steel and its preparation, which can solve the problems of high risk of equipment hazards, bending and skewing of rolled parts, difficult control of size, and high production costs. problem, to achieve the effect of solving the easy blockage of the nozzle, the high risk of equipment damage, and the small risk of equipment damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

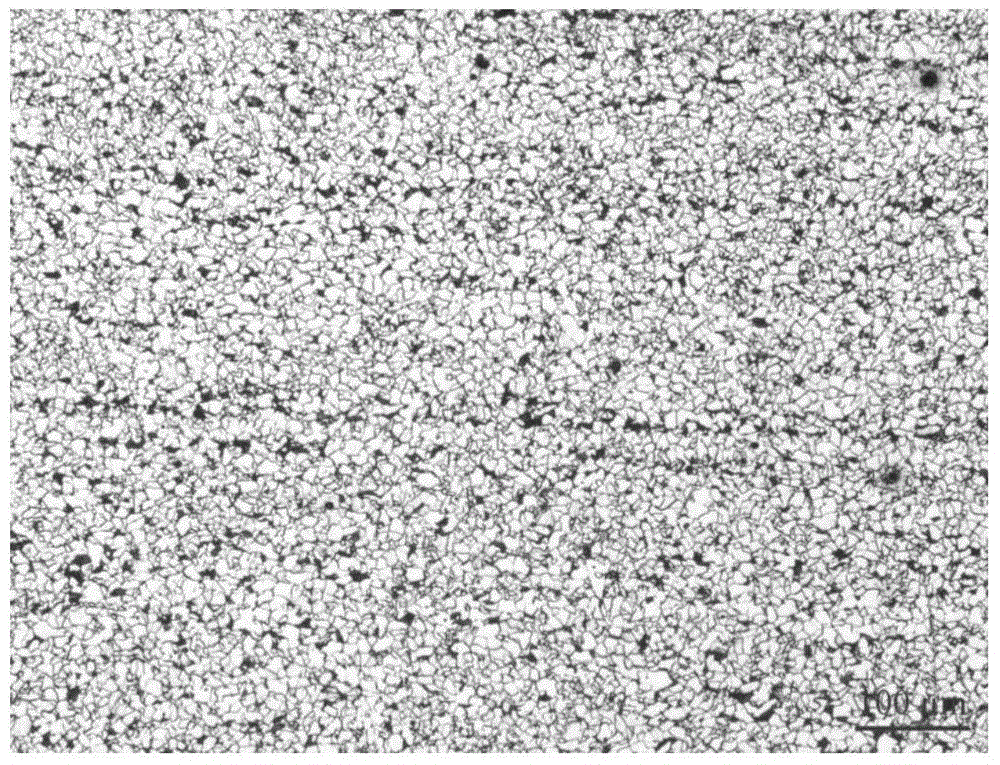

Embodiment 1

[0032] The chemical composition of the control profile is shown in Table 1.

[0033] 1) Converter smelting

[0034] Low sulfur and arsenic-containing blast furnace molten iron is generally required to have sulfur content [S] ≤ 0.02%, arsenic content [S] ≤ 0.0005%, and smelting end point control: [S] < 0.015%, [P] < 0.015%; The pretreated molten iron and high-quality steel scrap are added to the top-bottom combined blowing converter according to the designed ratio. The slag making system adopts the single slag process to reasonably control the basicity of the final slag and the target value of the end point; The process adopts aluminum-manganese-ferro deoxidation alloying, utilizes vanadium-iron and vanadium-nitrogen microalloying, controls target value according to vanadium microalloying alloy, adds vanadium-iron: vanadium-nitrogen=1:3 ratio, vanadium-iron and vanadium-nitrogen alloy in molten steel Add to 1 / 4 of the output, add to 3 / 4 of the output, and control the alkalinity ...

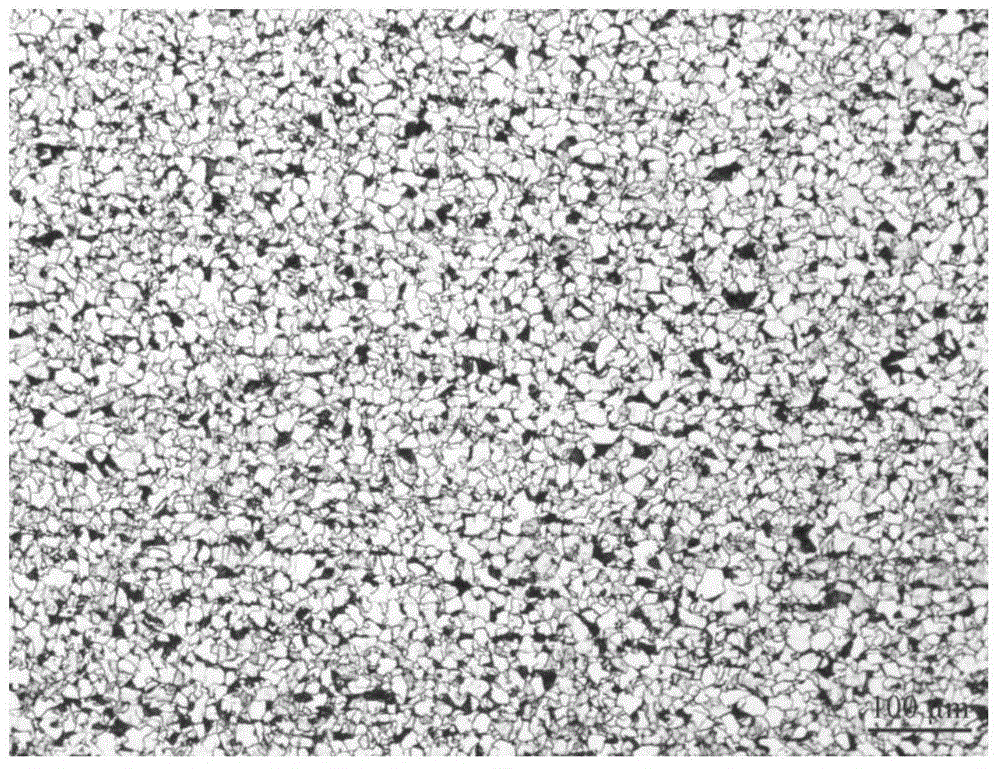

Embodiment 2

[0051] The chemical composition of the control profile is shown in Table 1.

[0052] 1) Converter smelting

[0053] Low sulfur and arsenic-containing blast furnace molten iron is generally required to have sulfur content [S] ≤ 0.02%, arsenic content [S] ≤ 0.0005%, and smelting end point control: [S] < 0.015%, [P] < 0.015%; The pretreated molten iron and high-quality steel scrap are added to the top-bottom combined blowing converter according to the designed ratio. The slag making system adopts the single slag process to reasonably control the basicity of the final slag and the target value of the end point; The process adopts aluminum-manganese-ferro deoxidation alloying, utilizes vanadium-iron and vanadium-nitrogen microalloying, controls target value according to vanadium microalloying alloy, adds vanadium-iron: vanadium-nitrogen=1:3 ratio, vanadium-iron and vanadium-nitrogen alloy in molten steel Add to 1 / 4 of the output, add to 3 / 4 of the output, and control the final rol...

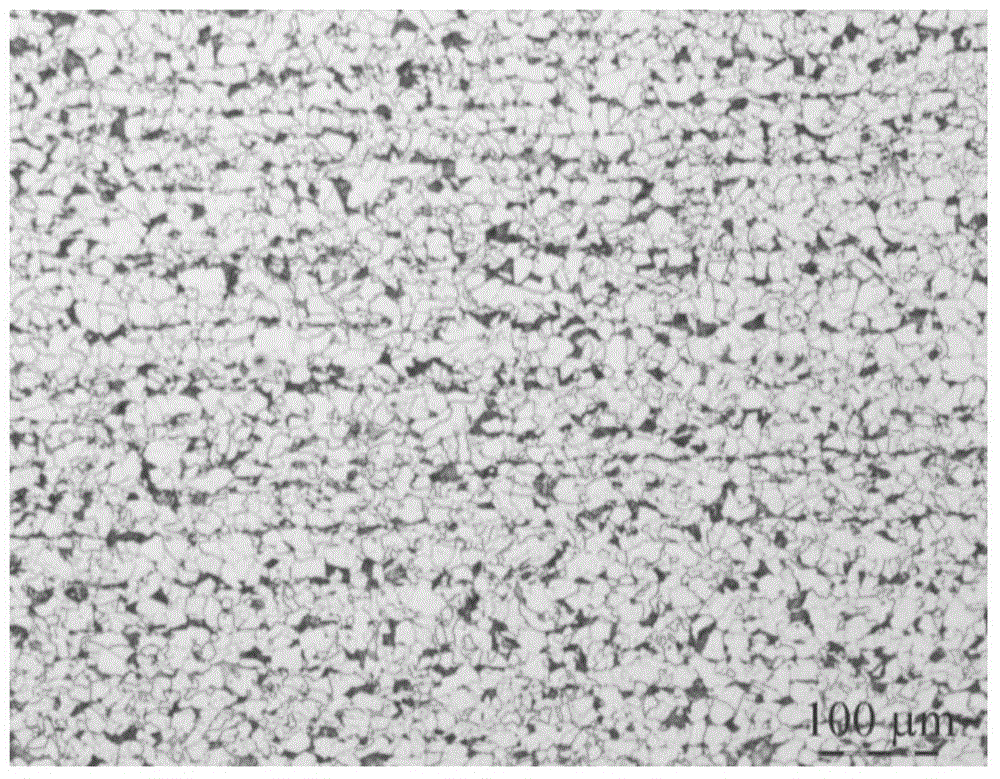

Embodiment 3

[0065] The chemical composition of the control profile is shown in Table 1.

[0066] 1) Converter smelting

[0067] Low sulfur and arsenic-containing blast furnace molten iron is generally required to have sulfur content [S] ≤ 0.02%, arsenic content [S] ≤ 0.0005%, and smelting end point control: [S] < 0.015%, [P] < 0.015%; The pretreated molten iron and high-quality steel scrap are added to the top-bottom combined blowing converter according to the designed ratio. The slag making system adopts the single slag process to reasonably control the basicity of the final slag and the target value of the end point; The process adopts aluminum-manganese-ferro deoxidation alloying, uses vanadium-iron and vanadium-nitrogen microalloying, controls the target value according to the vanadium microalloying alloy, adds vanadium-iron: vanadium-nitrogen=1:3 ratio, vanadium-iron and vanadium-nitrogen alloy in molten steel Add to 1 / 4 of the output, add to 3 / 4 of the output, and control the final...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com