Nano-structure electrode for energy storage device and pseudocapacitor having electrode

An energy storage device and nanostructure technology, which is applied in the field of pseudocapacitors and nanostructure electrodes, can solve the problems of low surface area utilization rate and difficulty in reaching the ideal level of FP actual capacity, and achieve the effect of improving utilization rate and capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

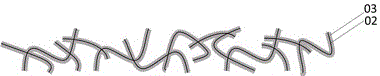

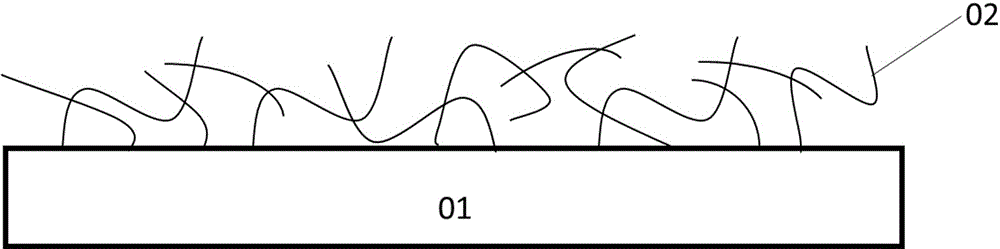

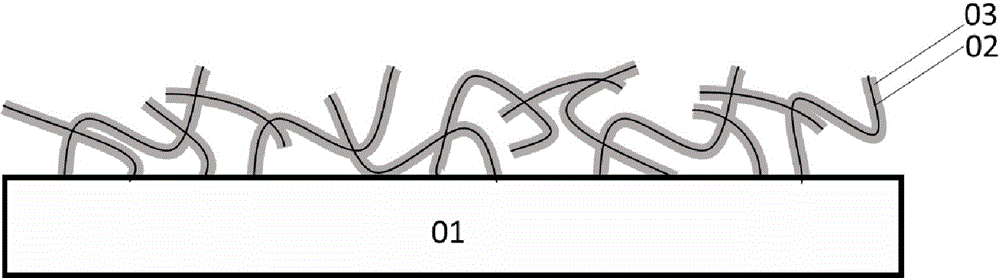

[0046] A nanostructured electrode for energy storage devices such as figure 1 As shown, there is an extraction electrode with interconnected metal nanostructures, and the surface of the extraction electrode is coated with an active layer 03 .

[0047] Specifically, the lead-out electrodes are metal nanowires 02 . The metal nanowire 02 has a diameter of 5 nm to 500 nm and a length greater than 5 um.

[0048] Specifically, the thickness of the active layer 03 is set to 1m~1000 nm, the active layer 03 can be formed by stacking one or more sub-active layers, and the material of each sub-active layer is transition metal oxide, conductive polymer Or any of the composite pseudocapacitive materials.

[0049] Among them, the transition metal oxide as the sub-active layer is specifically RuO 2 , MnO 2 、In 2 o 3 、MoO 3 , CuO, V 2 o 5 or TiO 2 any one or a combination of more than one.

[0050] The conductive polymer used as the sub-active layer is specifically polyaniline (PANi)...

Embodiment 2

[0062] A nanostructured electrode for energy storage devices such as Image 6 As shown, other structures are the same as those in Example 1, except that the nanostructure electrode is also provided with a modification layer 04, and the modification layer 04 is arranged between the surface of the lead-out electrode and the active layer 03. The modification layer can reduce the contact barrier between the active layer and the electrode surface and improve the charge transport efficiency.

[0063] The thickness of the modification layer 04 is 0.1 nm-10 nm. Specifically, the modification layer 04 is formed by stacking one or more sub-modification layers, and the material of the sub-modification layer is metal oxide, metal nitride or metal fluoride, specifically including: MgO, ZnO, CsO, TiN, MoN, LiF or CsF.

[0064] The nanoelectrode is prepared by the following steps:

[0065] (1) The metal nanowire 02 film is prepared on the flexible substrate 01 by using the solution proces...

Embodiment 3

[0074] A pseudocapacitor with the same structure as Figure 5 , prepared by the following method.

[0075] The Ag nanowire solution with a diameter of 120 nm was selected, and the Ag nanowire film 02 was prepared on the PI substrate 01 by screen printing processing method. Then use VO(OC 3 h 7 ) 3 As a V source precursor, use H 2 O was used as an oxygen source to coat Ag nanowires with 80 nm of V at 200 °C 2 o 5 as the active layer 03. Then select PEO / LiClO4 and polypropylene as the electrolyte 05 and diaphragm 06 to make a one-sided pseudocapacitor. Finally, two single-sided capacitors are attached on the diaphragm side to form a symmetrical capacitor.

[0076] Since the pseudocapacitor adopts nanometer electrodes with high surface area, it can have the characteristics of large capacity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com