Preparation method of NiCo<2>S<4>/carbon nanotube composite electrode material

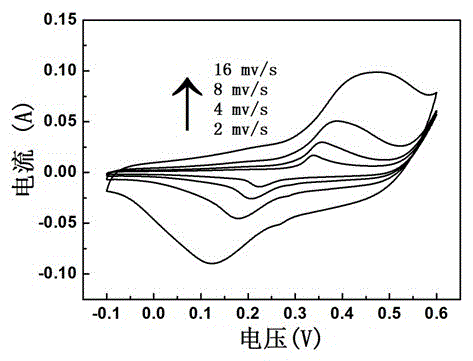

A carbon nanotube composite and carbon nanotube technology, which is applied in the field of composite materials, can solve unseen problems and achieve high specific capacitance value, good electrochemical performance stability, and strong binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

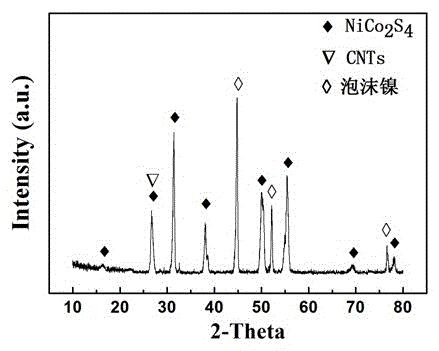

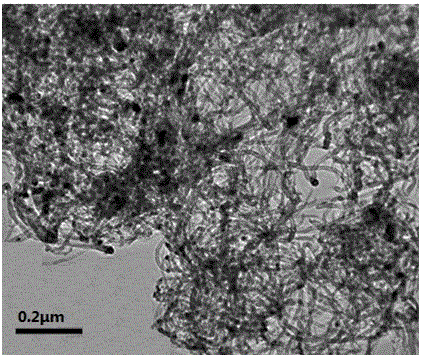

[0017] Specific implementation mode one: a kind of NiCo 2 S 4 The preparation method of the carbon nanotube composite electrode material is specifically completed according to the following steps.

[0018] 1. Preparation of carbon nanotube / nickel foam matrix: First, cut the nickel foam that has been ultrasonically cleaned with dilute hydrochloric acid, acetone, and absolute ethanol to 1*2cm; weigh 50mg of carbon nanotubes and 4.5mg of 60wt% polytetrafluoroethylene Dissolve it in 10ml of absolute ethanol and stir it into a slurry, then evenly coat it on the surface of 1*2cm nickel foam, and dry it in vacuum at 80°C to obtain a carbon nanotube / nickel foam matrix; the mass of carbon nanotubes loaded on the nickel foam 2mg / cm 3 .

[0019] 2. Preparation of electrodeposition solution: mix 1mmol Ni(NO 3 ) 2 ·6H 2 O and 2mmol Co(NO 3 ) 2 ·6H 2 O was dissolved in 100ml distilled water to prepare Ni 2+ / Co 2+ A mixed metal solution with a molar ratio of 1:2 was added, and 30...

specific Embodiment approach 2

[0021] Specific embodiment two: a kind of NiCo 2 S 4 The preparation method of the carbon nanotube composite electrode material is specifically completed according to the following steps.

[0022] 1. Preparation of carbon nanotube / nickel foam matrix: First, cut the nickel foam that has been ultrasonically cleaned with dilute hydrochloric acid, acetone, and absolute ethanol to 1*2cm; weigh 50mg of carbon nanotubes and 4.5mg of 60wt% polytetrafluoroethylene Dissolve it in 10ml of absolute ethanol and stir it into a slurry, then evenly coat it on the surface of 1*2cm nickel foam, and dry it in vacuum at 80°C to obtain a carbon nanotube / nickel foam matrix; the mass of carbon nanotubes loaded on the nickel foam 4mg / cm 3 .

[0023] 2. Preparation of electrodeposition solution: mix 2mmol Ni(NO 3 ) 2 ·6H 2 O and 4mmol Co(NO 3 ) 2 ·6H 2 O was dissolved in 100ml distilled water to prepare Ni 2+ / Co 2+ 100 mmol of thioacetamide was added to the mixed metal solution with a mola...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com