Metal electrode activation method for oxygen-metal battery

A metal battery and metal electrode technology, which is applied in the repair/maintenance of fuel cell half-cells, primary battery half-cells, and secondary batteries, to achieve the effects of increasing discharge power, reducing corrosion losses, and reducing side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

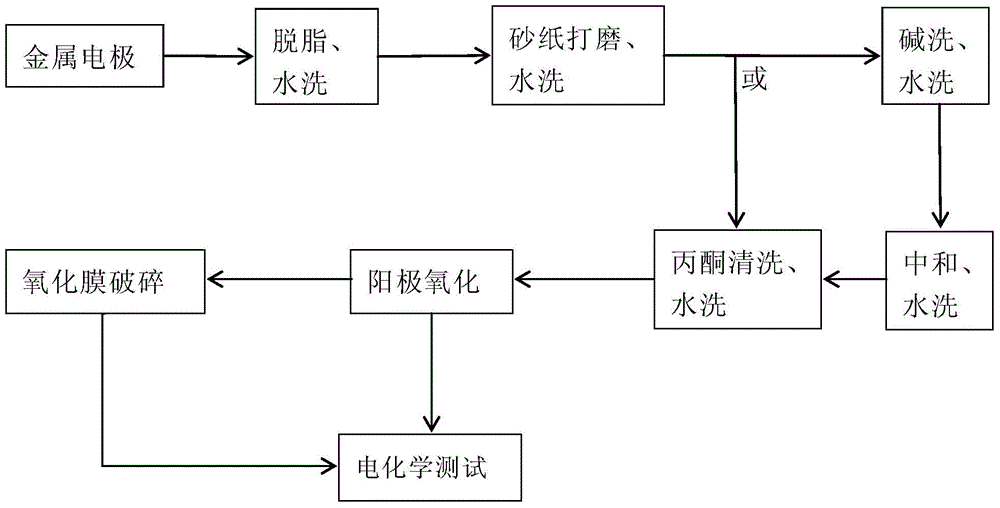

Method used

Image

Examples

Embodiment 1

[0025] Step 1: Degrease and polish

[0026] Clean the pre-prepared 5cm long, 1cm wide and 2mm thick aluminum plate with household detergent, and then sand it with No. 60, No. 240, No. 500, No. 800, No. 1000, and No. 2000 sandpaper. After polishing, wash it with water .

[0027] Step 2: Alkaline Wash

[0028] Prepare a 1mol / L NaOH solution, soak the polished aluminum plate in step 1 in the NaOH solution for 5 minutes, and then take it out and wash it with clean water.

[0029] Step Three: Neutralization

[0030] Put the aluminum plate cleaned in step 2 in 5mol / L HNO 3 In the solution for 10 seconds, take out and wash with water.

[0031] Step 4: Anodizing

[0032] Arrange the prefabricated 5cm long, 2cm wide, 2mm thick graphite plate and the aluminum plate of step 3 in parallel, and immerse in 15% H 2 SO 4 Among them, the two are immersed in 4cm and separated by 2cm. Adjust the current density to 10mA / cm 2 , Discharge at room temperature for 20 minutes, then take it ou...

Embodiment 2

[0046] Step 1: Degrease and polish

[0047] Clean the pre-prepared 5cm long, 1cm wide and 2mm thick magnesium board with household detergent, and then polish it with No. 60, No. 240, No. 500, No. 800, No. 1000, and No. 2000 sandpaper, and wash it with water after polishing net.

[0048] Step 2: Acetone Cleaning

[0049] Soak the polished aluminum plate in step 1 in acetone for 5 minutes, take it out and wash it with clean water.

[0050] Step 3: Anodizing

[0051] Arrange the pre-prepared 5cm long, 2cm wide, 2mm thick graphite plates and the magnesium plates of step 2 in parallel, and immerse them in the electrolyte. The proportion of the electrolyte is 2mol / L of KOH, 0.5mol / L of Na 2 CO 3 , 1mol / L Na 2 SiO 3 , graphite plate and magnesium plate immersed in 4cm, 2cm apart. Adjust the current density to 10mA / cm 2 , Discharge at room temperature for 30 minutes, then take it out, wash it with water, and dry it with a hair dryer.

[0052] Step 4: Broken oxide film

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com