Synthetic method for rubber cross-linking agent cyclohexanone peroxide

A technology of cyclohexanone peroxide and synthesis method, which is applied in the field of organic synthesis, can solve problems such as endangering the health of production operators and environmental pollution, and achieve the effects of prolonging the service life of equipment, reducing the risk factor, and improving the reaction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

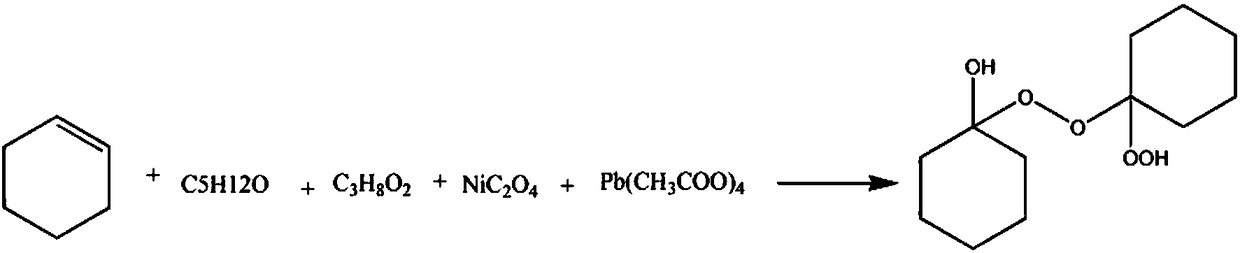

[0016] The synthetic method of rubber crosslinking agent cyclohexanone peroxide comprises the steps:

[0017] A: Add 2mol cyclohexene in the reaction vessel, 800ml mass fraction is 40% potassium nitrate solution, control the solution temperature to 15°C, control the stirring speed to 210rpm, add 4mol mass fraction to be 30% 1,2-propanediol solution, 4mol four For lead acetate, add 4mol mass fraction of 40% methyl tert-butyl ether solution in 2 times within 30 minutes, and continue to react for 80 minutes;

[0018] B: Then add 4mol nickel oxalate powder, control the stirring speed to 290rpm, continue to react at 120rpm, react for 2h, lower the temperature to 5°C, add 1.3L of 10% sodium sulfate solution by mass fraction, separate the layers of the solution, separate the oil layer, and use the mass fraction Wash with 60% hexane solution for 30 minutes, recrystallize in 70% butyl ether solution, and dehydrate with anhydrous sodium sulfate dehydrating agent to obtain 480.684 g of f...

Embodiment 2

[0020] The synthetic method of rubber crosslinking agent cyclohexanone peroxide comprises the steps:

[0021] A: Add 2mol cyclohexene in the reaction vessel, 800ml mass fraction is 43% potassium nitrate solution, control the solution temperature to 18°C, control the stirring speed at 220rpm, add 5mol mass fraction to be 33% 1,2-propanediol solution, 5mol four For lead acetate, add 5mol mass fraction of 44% methyl tert-butyl ether solution in 3 times within 40 minutes, and continue to react for 100 minutes;

[0022] B: Then add 5mol nickel oxalate powder, control the stirring speed to 310rpm, continue to react at 140rpm, react for 2.5h, lower the temperature to 7°C, add 1.3L of 13% sodium sulfate solution, the solution is separated, the oil layer is separated, and the Wash with 63% hexane solution for 40 minutes, recrystallize in 73% butyl ether solution, and dehydrate with anhydrous sodium sulfate dehydrating agent to obtain 481.668 g of finished cyclohexanone peroxide with a ...

Embodiment 3

[0024] The synthetic method of rubber crosslinking agent cyclohexanone peroxide comprises the steps:

[0025] A: Add 2mol cyclohexene in the reaction vessel, 800ml mass fraction is 47% potassium nitrate solution, control the solution temperature to 22°C, control the stirring speed to 230rpm, add 6mol mass fraction to be 36% 1,2-propanediol solution, 6mol four For lead acetate, add 6mol mass fraction of 47% methyl tert-butyl ether solution in 4 times within 50 minutes, and continue to react for 120 minutes;

[0026] B: Then add 6mol of nickel oxalate powder, control the stirring speed to 320rpm, continue to react at 160rpm, react for 3h, lower the temperature to 9°C, add 1.3L of 16% sodium sulfate solution by mass fraction, separate the layers of the solution, separate the oil layer, and use the mass fraction Wash with 65% hexane solution for 50 minutes, recrystallize in 76% butyl ether solution, and dehydrate with anhydrous sodium sulfate dehydrating agent to obtain 483.144 g ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com